Premium Only Content

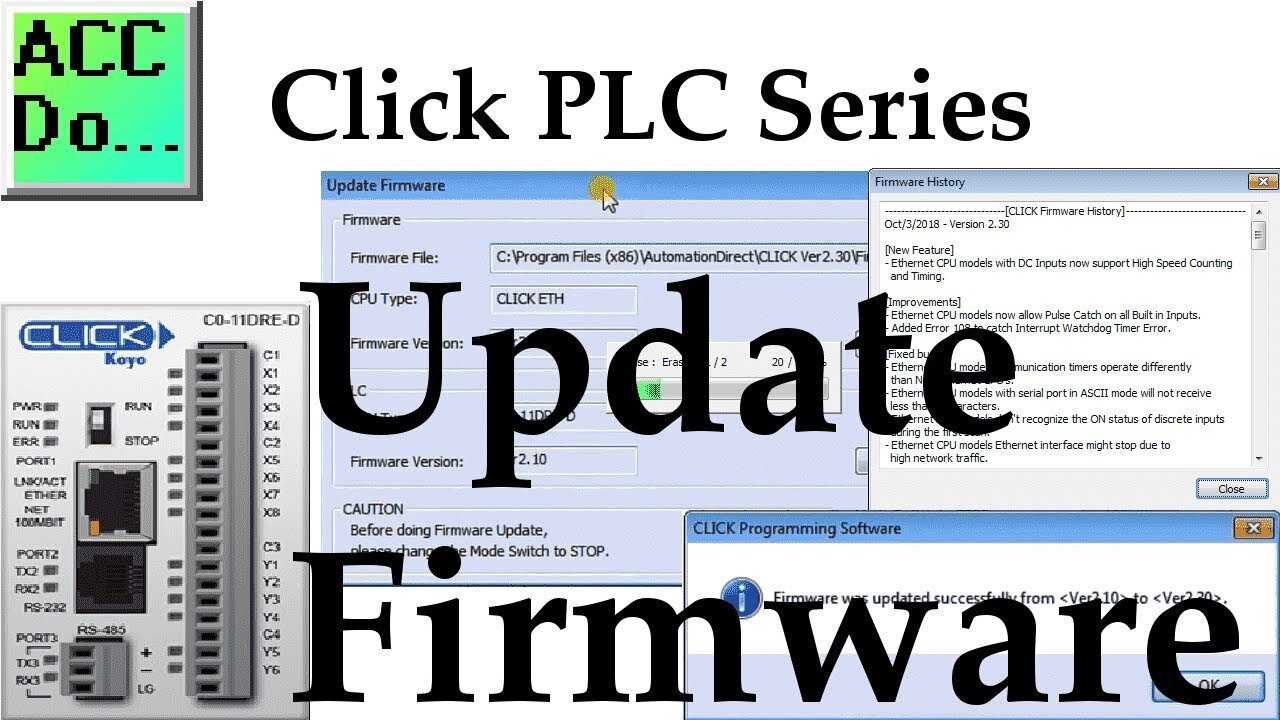

Click PLC Update Firmware

We will now update the firmware on our Click PLC. Firmware is usually PLC operating system code that is written into a read-only memory. The BIOS (Basic Input Output System) of a PC (personal computer) is a good example of firmware. It provides a low-level interface between the hardware and software. The Click PLC firmware comes with the programming software.

https://support.automationdirect.com/products/clickplcs.html

We will be updating the firmware of our Click PLC from 2.10 to 2.30. Let's get started!

More information can be obtained on our website. This includes all of the links mentioned in this video.

http://accautomation.ca/click-plc-update-firmware

Previously we discussed:

Click PLC System-Hardware.

http://accautomation.ca/click-plc-system-hardware/

Click PLC Installing the Software

http://accautomation.ca/click-plc-installing-the-software/

Click PLC Establish Communication

http://accautomation.ca/click-plc-establish-communication/

Click PLC Numbering System and Addressing

http://accautomation.ca/click-plc-numbering-system-and-addressing

Click PLC Timers and Counters

http://accautomation.ca/click-plc-timers-and-counters

Click PLC Compare and Math Instructions

http://accautomation.ca/click-plc-compare-and-math-instructions

Click PLC Program Control Instructions

http://accautomation.ca/click-plc-program-control-instructions

Click PLC Shift Register Instruction

http://accautomation.ca/click-plc-shift-register-instruction

Click PLC Drum Instruction

http://accautomation.ca/click-plc-drum-instruction

Click PLC Send and Receive Instructions

http://accautomation.ca/click-plc-send-and-receive-instructions

Click PLC AdvancedHMI Communication

http://accautomation.ca/click-plc-advancedhmi-communication

Modbus RTU Click PLC Master to BRX PLC Slave Communication

http://accautomation.ca/modbus-rtu-click-plc-master-to-brx-plc-slave-communication

Video

https://youtu.be/CIsj-Xppoog

There are several reasons why we are using the Click PLC. Here are just a few.

- Investment is low for the hardware and the software is free

- Standalone PLC with built-in I/O

- Communication ability - Ethernet Port, RS232, RS485 - support for protocols such as Modbus RTU, Modbus TCP, etc.

- Ability to expand the system with a variety of modules including RTD and Thermocouple inputs directly.

-

2:55:39

2:55:39

Barry Cunningham

1 day agoBREAKING NEWS: DID PRESIDENT TRUMP MAKE A HUGE MISTAKE? SOME SUPPORTERS THINK SO!

48.3K31 -

LIVE

LIVE

SpartakusLIVE

5 hours agoSOLOS on WZ || #1 Challenge MASTER is BACK in Verdansk

325 watching -

2:49:38

2:49:38

megimu32

4 hours agoOFF THE SUBJECT: Chill Stream, Music & Fortnite Chaos 🎹🎮

27.4K4 -

2:24:09

2:24:09

vivafrei

14 hours agoEp. 290: Canada's Darkest Week; Comey Fix is In! Tariffs, SNAP, Hush Money Win & MORE!

226K181 -

5:01:48

5:01:48

EricJohnPizzaArtist

5 days agoAwesome Sauce PIZZA ART LIVE Ep. #68: DDayCobra Jeremy Prime!

28.6K12 -

LIVE

LIVE

meleegames

4 hours ago32X Roulette - 30 Years. 32 Games. 32X.

89 watching -

SOLTEKGG

3 hours ago(30+ KILL WORLD RECORD) - Battlefield 6

6.76K1 -

1:18:00

1:18:00

HELMETFIRE

4 hours ago🟢GAMING WITH FIRE EP15🟢

6K -

3:18:34

3:18:34

BubbaSZN

4 hours ago🔴 LIVE - FARTNITE W/ @CATDOG & @CHEAP

10.2K1 -

2:54:01

2:54:01

LadyDesireeMusic

7 hours ago $7.58 earnedCookin & Convo - Potato Soup, Ham & Apple Pie

40.9K5