Premium Only Content

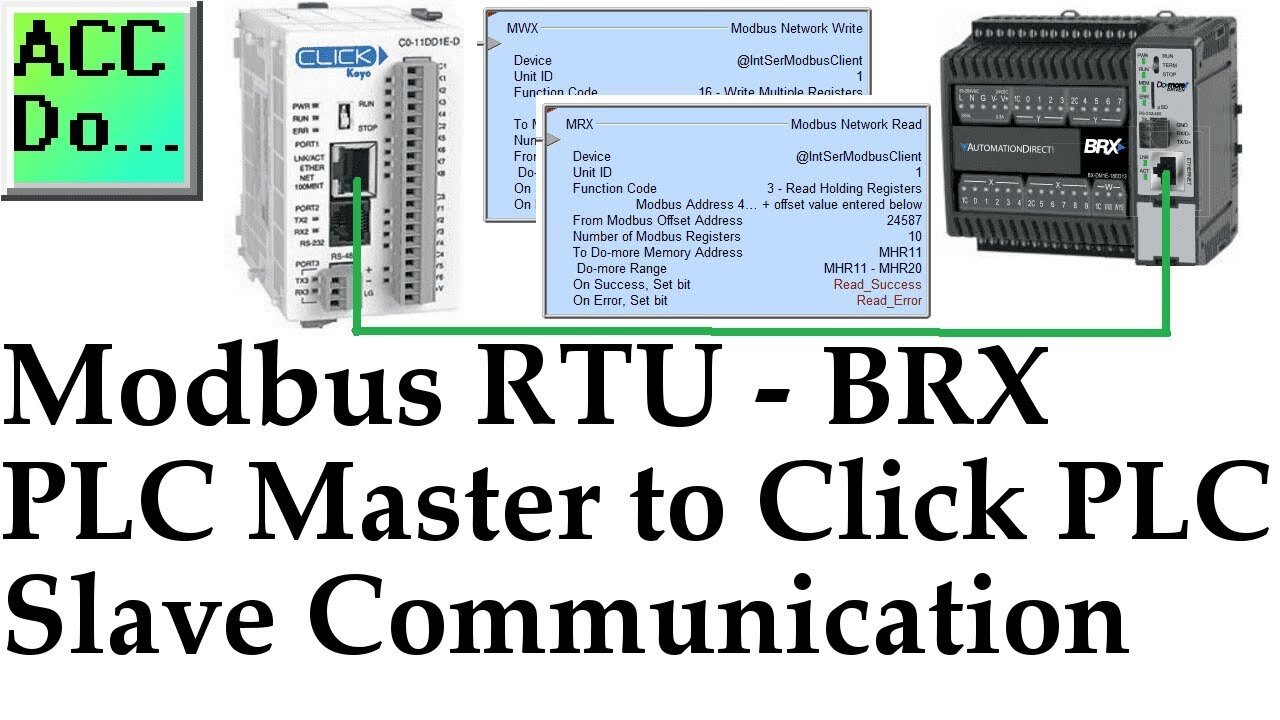

Modbus RTU BRX Do-More Master to Click Slave PLC

Recently I was asked to demonstrate communication between a BRX PLC and Click PLC using Modbus RTU. Both PLCs are available from automation direct com. Modbus serial communication (Modbus RTU) is a standard protocol used in many automation devices. It works on a Master / Slave configuration. You can have only one master per network on Modbus RTU (Remote Terminal Unit). A maximum of 32 devices (Nodes) on the network can communicate to the master. A review of the Modbus RTU protocol (RTU frames) can be seen at the following URL.

https://www.rtaautomation.com/technologies/modbus-rtu/

Using the BRX PLC as a Master, we will be communicating to the Click PLC (Slave). Our example will read 10 registers from the Click PLC and write 10 registers from the BRX PLC. Let's get started!

More information can be obtained at our website. This includes all of the links mentioned in this video.

https://accautomation.ca/modbus-rtu-brx-plc-master-to-click-plc-slave-communication

00:00 Modbus RTU BRX Do-More Master to Click Slave PLC

00:24 Overview of Communication - Modbus

01:40 Modbus RTU (RS485) Wiring

02:16 Click PLC Setup and Program for Modbus RTU Slave Unit

03:21 BRX Do-More PLC Setup and Program for Modbus RTU Master Unit

07:45 Running the programs and testing communication

This post is part of our BRX Series PLC. Here are some of the topics that we have already covered in this series.

System Hardware

https://accautomation.ca/brx-plc-system-hardware

System Hardware Video

https://youtu.be/wSYgY09VYeA

Unboxing Video

https://youtu.be/-Tf8m3BqzPo

Installing the Software

https://accautomation.ca/brx-plc-installing-the-software

Installing the Software Video

https://youtu.be/iFI1ebP8Zkk

Establishing Communication

https://accautomation.ca/brx-plc-establishing-communication

Establishing Communication Video

https://youtu.be/shU5g8MA8VM

Updating Firmware Video

https://youtu.be/gsfcGGK4-Sk

Numbering Systems and Addressing

https://accautomation.ca/brx-plc-numbering-systems-and-addressing

Numbering Systems and Addressing Video

https://youtu.be/-GiKnIDycKY

First Program

https://accautomation.ca/brx-plc-first-program

First Program Video

https://youtu.be/ANSNhdlm_Ao

Monitoring and Testing the Program

https://accautomation.ca/brx-plc-monitoring-and-testing-the-program

Monitoring and Testing the Program Video

https://youtu.be/gv3d0vozxac

Online Editing and Debug Mode

https://accautomation.ca/brx-plc-online-editing-and-debug-mode

Online Editing and Debug Mode Video

https://youtu.be/77pemu3zXrE

Timers

https://accautomation.ca/brx-plc-timers

Timers Video

https://youtu.be/0qU9kgunPi4

Counters

https://accautomation.ca/brx-plc-counters

Counters Video

https://youtu.be/k84VQy8ifgg

High-Speed IO

https://accautomation.ca/brx-plc-high-speed-io

High-Speed IO Video

https://youtu.be/6B5hp_Ri0Ls

There are several reasons why we are using the BRX Series Controller. Here are just a few.

- Standalone PLC with built-in I/O

- Built-in Data Logging

- Communication ability - Ethernet Port, RS232, RS485, USB - support for protocols such as Modbus RTU, Modbus TCP, ASCII, K-sequence (DirectLOGIC users), Custom Protocols (ASCII over serial, TCP or UDP over Ethernet)

- Built-in Analog input and output

- Integrated motion control

- High-speed counters

- Powerful instruction set (Video of Instructions in software)

- Ability to expand the system with a variety of modules

- Part of the Do-More series of PLCs which use the same free software. (Do-More Designer)

- Integrated simulator in the software capable of external communications for testing

The BRX series of programmable logic controllers consist of four different units. They differ depending on the Inputs and Outputs built into the unit and if it has an ethernet port.

No I/O Micro PLC unit – (BX ME)

10 Point Micro PLC unit – (BX 10/10E)

18 Point Micro PLC unit - (BX 18/18E)

36 Point Micro PLC unit - (BX 36/36E)

These CPUs (Central Processing Units) are also known as MPU (Multi-Processing Units) because of their communication capabilities.

-

LIVE

LIVE

vivafrei

8 hours agoEp. 290: Canada's Darkest Week; Comey Fix is In! Tariffs, SNAP, Hush Money Win & MORE!

15,945 watching -

LIVE

LIVE

MattMorseTV

1 hour ago🔴Senate VOTES to END the SHUTDOWN.🔴

1,842 watching -

3:05:05

3:05:05

GamerGril

5 hours agoThere's A Killer Afoot 💞Until Dawn: The Final Gril💞

60.2K3 -

LIVE

LIVE

LadyDesireeMusic

1 hour agoCookin & Convo - Potato Soup, Ham & Apple Pie

306 watching -

51:25

51:25

The Connect: With Johnny Mitchell

1 day ago $37.76 earnedInside The REAL Narco State: The Colombian Drug Cartels DOMINATING The Global Cocaine Trade

54.6K30 -

LIVE

LIVE

bucketofish

2 hours ago///ARC Raiders || Loot, Scoot + Boogie

47 watching -

5:41:25

5:41:25

GritsGG

6 hours ago#1 Most Warzone Wins 3953+!

29.8K2 -

LIVE

LIVE

Spartan

2 hours agoGetting to DLC Boss on Stellar Blade (Hard Mode), then moving on to something else.

32 watching -

![THIS GAME IS SO OLD :: Half-Life (1998) :: FINISHING IT TODAY [FIRST TIME PLAYING] {18+}](https://1a-1791.com/video/fww1/5e/s8/1/A/6/a/y/A6ayz.0kob-small-THIS-GAME-IS-SO-OLD-Half-Li.jpg) LIVE

LIVE

a12cat34dog

4 hours agoTHIS GAME IS SO OLD :: Half-Life (1998) :: FINISHING IT TODAY [FIRST TIME PLAYING] {18+}

134 watching -

10:23

10:23

Forrest Galante

12 hours agoAsking an Indian Billionaire Why He Is Saving 1 Million Animals

95.5K34