Premium Only Content

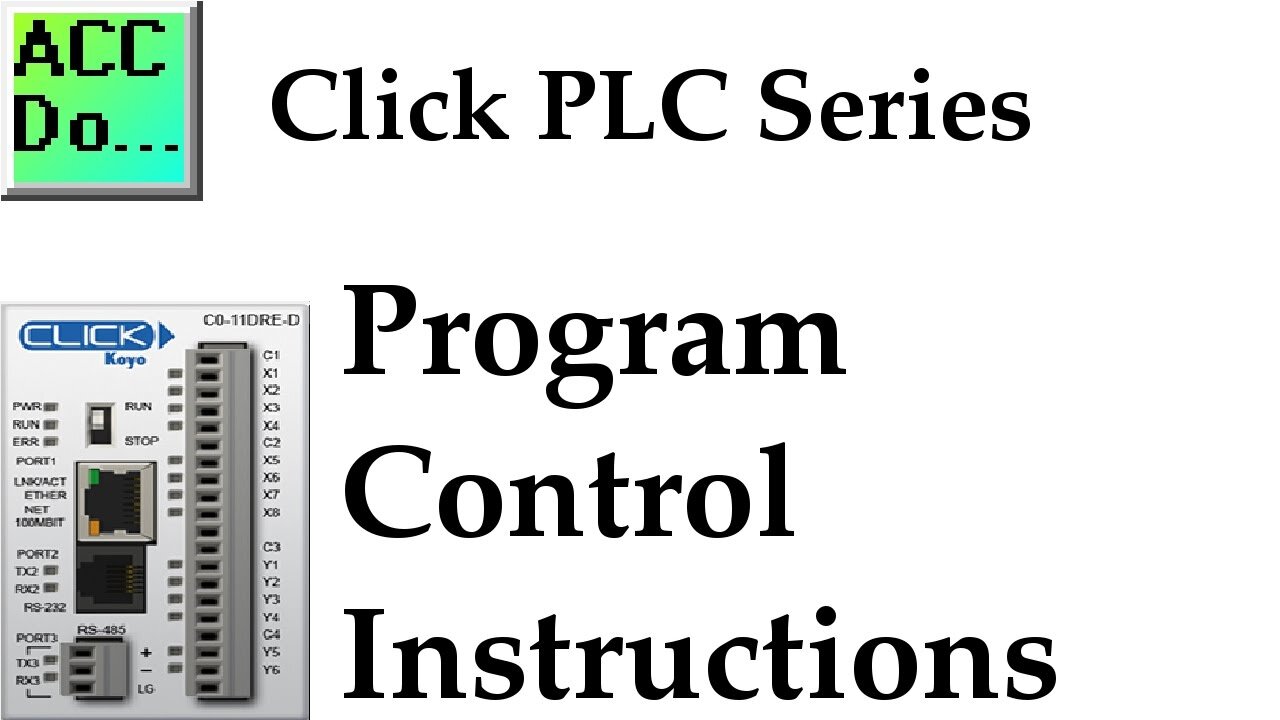

Click PLC Program Control Instructions

We will now look at the click plc program control instructions available to you.

The program control instructions will allow us to specify what parts of the logic get solved and when this happens. This will control how the PLC will scan and solve your logic in your program.

Program control (flow) instructions in the Click PLC will utilize interrupts and subroutines. In the last post on Click PLC Compare and Math Instructions, we discussed interrupts. They can be timed or event (Built-in inputs on the CPU.) When the interrupt happens it will immediately go and solve the logic in the interrupt and then return to the instruction following the location that it was called. This can and will happen at any time throughout the scan of the PLC.

More information can be obtained on our website. This includes all of the links mentioned in this video.

https://accautomation.ca/click-plc-program-control-instructions

00:00 Click PLC program control

00:23 Click PLC Interrupts

01:45 Interrupt Setup

02:35 Click PLC Subroutines

03:12 Calling subroutines - Main PLC

04:33 Testing our PLC Program Control

Previously we discussed:

Click PLC System-Hardware.

https://accautomation.ca/click-plc-system-hardware/

Click PLC Installing the Software

https://accautomation.ca/click-plc-installing-the-software/

Click PLC Establish Communication

https://accautomation.ca/click-plc-establish-communication/

Click PLC Numbering System and Addressing

https://accautomation.ca/click-plc-numbering-system-and-addressing

Click PLC Timers and Counters

https://accautomation.ca/click-plc-timers-and-counters

Click PLC Compare and Math Instructions

https://accautomation.ca/click-plc-compare-and-math-instructions

Download the Click Programming software at the following address:

https://support.automationdirect.com/products/clickplcs.html

There are several reasons why we are using the Click PLC. Here are just a few.

- Investment is low for the hardware and the software is free

- Standalone PLC with built-in I/O

- Communication ability - Ethernet Port, RS232, RS485 - support for protocols such as Modbus RTU, Modbus TCP, etc.

- Ability to expand the system with a variety of modules including RTD and Thermocouple inputs directly.

-

LIVE

LIVE

meleegames

2 hours agoSONG REQUESTS CLOSED - Melee Music - Beat Hazard 3 - Devil Inside

133 watching -

LIVE

LIVE

The Connect: With Johnny Mitchell

9 hours agoIs Garth Brooks A Serial Killer? Exposing The Dark Secrets Of Country Music's Biggest Star

174 watching -

1:00:49

1:00:49

MattMorseTV

2 hours ago $53.63 earned🔴Massive VICTORY in the SUPREME COURT.🔴

71.9K64 -

LIVE

LIVE

GritsGG

1 hour ago#1 Most Warzone Wins 4015+!

84 watching -

4:20:08

4:20:08

Biscotti-B23

4 hours ago🔴 LIVE STREAM ENDS WHEN I GET 100 WINS 🥵 INVINCIBLE VS CLOSED ALPHA

2.66K1 -

12:38

12:38

Timcast

1 day agoJasmine Crocket HUMILIATED By CNN To HER FACE Over Epstein LIE | Tim Pool

102K73 -

19:32

19:32

MetatronHistory

22 hours agoWas Nazism Left Wing or Right Wing? An Answer From History

23.4K49 -

1:54:20

1:54:20

Mally_Mouse

22 hours ago🌶️ 🥵Spicy BITE Saturday!! 🥵🌶️- Let's Play: Human Fall Flat

62K3 -

4:36

4:36

GreenMan Studio

4 hours agoTHE RUMBLE COLLAB SHOW EP. 5 W/Greenman Reports

1.35K3 -

LIVE

LIVE

ShitShow Gaming

6 hours agoOUTLAST 2 IN 2025. . . | #WWP #horrorgames #multistream

7 watching