Premium Only Content

Rollsizing brass to eliminate case bulge after firing

There have been numerous methods developed to eliminate the inevitable "bulge" in fired brass cases. Effectively what happens when you fire a typical handgun is the case expands disproportionately at the base of the case where it is allowed to do so due to clearance in the chamber. This prevents excessive pressure buildup and allows the case to take the brunt of this combustion pressure.

The problem that arises is that typical full length re-sizing dies cannot fully resize the case right to the very bottom of the case because of the thickness of the shell plate on your reloading press. This thickness means the sizing die can only reach the top of the shell plate while the bottom of the case sits in the shell case below the top of the shell plate. After full length sizing, the bulge often remains. This is more prevalent with guns having a generous chamber tolerance like service weapons but also with heavy powder loads. Nevertheless it becomes a problem even with light loads as many firings tends to build the bulge further and further and often to the point where case separation from the case head occurs, or more annoying the rounds fail to feed correctly or worse still jam in the action.

The remedy is to Rollsize all cases after firing before one does the final full length sizing during the reloading process on your reloading press.

This process brings the case geometrically back to specification just like brand new cases. It also extends the possible reloading cycles of your cases.

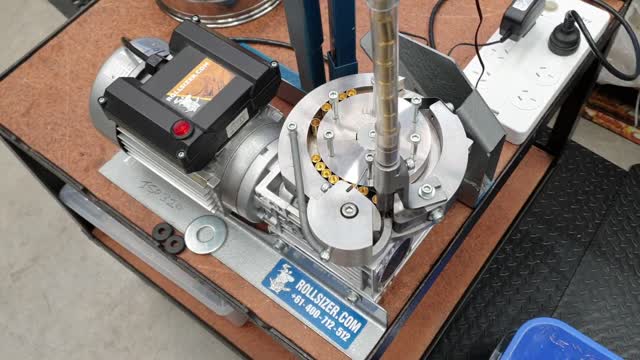

Shown here is an automated Rollsizing machine with a very quick cycle rate. The same manufacturer has a home consumer model which is slower in processing speed but ideal for the lower volume reloader.

Most importantly, you will always have the most consistent and reliably cycling ammunition in your gun by adding this important step to your ammo reloading process.

-

3:50

3:50

Reloading technology

3 years ago $0.12 earnedUnloading brass tumbler tank

6052 -

0:59

0:59

New York Post

4 years agoBill Burr called Gina Carano a sweetheart after her firing

5.52K39 -

0:53

0:53

WXYZ

4 years agoDuron Harmon talks Lions life after Patricia's firing

37 -

1:32

1:32

WXYZ

4 years agoMan arrested after firing at officers

2951 -

0:38

0:38

A Bikers Life

4 years ago $0.02 earnedTest firing Gypsy after doing repair work on her

114 -

2:08

2:08

KNXV

4 years agoWhat's changed in policing after Floyd case

7 -

4:04

4:04

The Classic Metal Show | Chris Akin Stuff

4 years agoCMSN | Noon Noize 5.27.21 - David Ellefson Comments After Firing From Megadeth

40 -

1:03:57

1:03:57

The Amber May Show

3 hours agoShattering the Narrative: Trump, Media Collapse & The Rising Chaos

5K2 -

LIVE

LIVE

LFA TV

23 hours agoLFA TV ALL DAY STREAM - MONDAY 7/28/25

625 watching -

DVR

DVR

freecastle

8 hours agoTAKE UP YOUR CROSS- STOP the Hate From State to State!

14.8K4