Premium Only Content

4K Walk - Quivira Road Viaduct

I took a walk up the ramps that lead up to the top of the bridge at the Quivira Road Viaduct in Overland Park, Kansas. Footage taken on a windy Saturday afternoon, March 27th, 2021.

Q UIVIRA ROAD IS A MAJOR NORTHSOUTH ARTERIAL ROUTE THROUGH LENAXA, KS, and several other suburbs on the

west side of Kansas City. Unfortunately, the roadway was discontinuous at its intersection with I-35, which caused traffic headaches and congestion on nearby roads. The solution to this problem, the Quivira Road Viaduct, was completed in June 1994. The new viaduct crosses two frontage roads, I-35, a parking lot, a retail lumberyard warehouse, two BurlingtonNorthern railroad tracks and a local access street—and the skew angle for most of these crossings is in excess of 50

degrees. Preliminary studies were performed to determine the best structural system for the viaduct and haunched steel welded plate girders were chosen over prestressed concrete girders because of the requirement for longer spans over the Interstate and the need to reduce the number of substructure members in the parking lot of the retail

business below the viaduct. The haunched welded plate girders also created an attractive appearance. The desired roadway template for the

viaduct varied from four lanes at the south end to five lanes at the north end. After considering several options, an open median structure was used for the south portion and a closed median was used at the north end. The open median and single column bents on the south

portion provided the distinct benefit of allowing the spans to be constructed without the 50+ degree skew. Span lengths for the parallel bridges were identical but reversed from north to south on the open median portion of the viaduct. This redundancy lead to economy in both design and construction. The south approach structure is a 333’ stabilized earth structure. Nine spans totaling 1,195’ with a maximum

span length of 160’ make up the open portion of the viaduct. The girders have straight haunches to match the tapered piers and are painted an earth tone to match the bridge rail, fence and street lights. An intumescent coating was applied to the spans above the warehouse to provide a thermal barrier that would give fire officials time to close the

viaduct in case of fire in the warehouse below. Each portion of the open median structure, northbound and southbound, carries a 30’-wide roadway and a 6’-wide sidewalk. Northbound and southbound roadways share common end bents but otherwise are on separate single column bents. The closed median portion of the viaduct consists of three spans totaling 396’ with a maximum span length of 160’. These girders are tapered and painted like the open median spans and carry a 71’-wide roadway and one 6’-wide sidewalk. These spans sit on multiple column bents that create the appearance of a series of single column bents that are under the south part of the viaduct. The north approach structure is a 290’-long mechanically stabilized earth structure.

Prior to the construction of the viaduct, Santa Fe Trail Drive intersected 87th Street Parkway at Quivira Drive. Construction of the viaduct eliminated this connection, so southbound traffic on Santa Fe Trail Drive now exits Quivira Road before raching the viaduct and an aerial signalized intersection was added between northbound Santa Fe Trail Drive and Quivira Road on the viaduct. This structure, called the Santa

Fe Trail Ramp, consists of a 200’-long mechanically stabilized earth approach structure, a three-span 230’-long curved steel welded plate girder main structure and a 43’-long flared steel welded plate girder jump span. The presence of the signalized aerial intersection results in more starts and stops and there was concern that this would create the need for additional deicing chemicals, which could be detrimental to the bridge deck. To prevent the arbitrary application of excessive amounts of de-icing chemicals, a moisture monitoring system was incorporated into the structure. The sensors are connected to a small on-site weather

station, which is connected to the local transportation weather monitoring and forecasting network. The completed viaduct carries more than 18,500 vehicles per day and has reduced the traffic on the 87th Street Parkway and the I-35 interchange by 5,000 vehicles per day.

Project Team Designer:

Bucher, Willis, & Ratliff

Corporation

Kansas City, MO

General Contractor & Erector:

APAC-Kansas, Inc.

Wilkerson-Maxwell Division

Kansas City, MO

Fabricator: DeLong’s Inc.

Jefferson City, MO

Owner: City of Lenexa, KS

Project Data:

Steel wt./sq. ft. of deck: 29.12 lbs

Cost: $10.5 million

Steel Tonnage: 1,519

-

19:05

19:05

Joe_The_Fenceman

4 years agoReading Railroad Viaduct

37 -

0:30

0:30

Pelmorex_Eng

4 years agoExcited for a snowy walk down the road

19 -

2:59

2:59

Ferrovia Sul

4 years ago $0.01 earnedBrazil TRAIN RUMO three SD40 locomotives on Paraná Viaduct

110 -

2:13

2:13

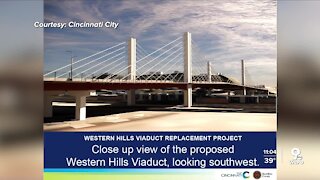

WCPO

4 years agoWhat the Western Hills Viaduct replacement could look like

17 -

1:57

1:57

helitack32f1

4 years agoLocomotive walk around

57 -

0:23

0:23

1984 M1010 Campulance

4 years agoRoad test

271 -

0:19

0:19

Official "Japanese daily life" Vlogs

4 years agoHoliday walk

19 -

0:51

0:51

chetkane

4 years agoSpring walk on the river walk

9 -

0:37

0:37

Muka

4 years agoA cat's walk.

24 -

1:00:00

1:00:00

BEK TV

2 days agoMIKE MOTSCHENBACHER ON NORTH DAKOTA POLITICS, TEA PARTY ROOTS, AND THE 2026 ELECTION

18.9K