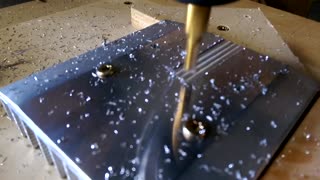

CNC - simple G code drill operation into soft plastic

This video shows a basic drill operation using a few lines of G code.

The spindle was manually adjusted into position using Chilipeppr software before starting the operation.

I found it fairly quick to program just automate 1 drill operation then go the the next location and stop. If nothing went wrong, just click the run button again to start the next hole..

Here is G-code with additional spindle automation and lots of comments:

(Drill holes and go to next position to prepare for next hole.)

(Drill bit size #23, 20-55 RPM. Soft plastic)

(Only drill ? holes at a time to allow clearing of shavings)

(Set bit about 1/4" above work piece)

G20

M03 (SPINDLE ON clockwise)

G04 P5.0(Wait for spindle to ramp up)

G91 G01 F20 Z-0.50 (Drill hole - G91 is incremental mode, G01=move at feedrate F, G00 is move at max rate)

G91 G00 Z0.50 (raise drill out of material)

G91 G00 X1.00 (Go to hole 2 location 1" on x axis)

(repeat as needed for more holes)

(End of drilling)

M05 (stop spindle)

M02 (end program)

-

0:32

0:32

Electronic Investigation

3 years agoCNC aluminum with simple G code -early testing

923 -

3:06

3:06

Reuters Innovation

3 years agoPaving the way: Kenyan recycles plastic into bricks

168 -

0:28

0:28

Rich_Stadler

3 years ago $0.02 earnedCnc plastic routing

82 -

16:40

16:40

MGSHAF2

3 years agoA SIMPLE HOW-TO!

1392 -

0:47

0:47

5DogsInc

3 years agoSimple Joy!

84 -

3:55

3:55

LearnHowToQuilt

3 years ago $0.01 earnedSimple Table Runners

1101 -

6:34:36

6:34:36

SilverFox

20 hours ago🔴LIVE - Elden Ring NEW Play Through Who Dis?

32.8K1 -

2:05:21

2:05:21

Barstool Yak

8 hours agoSteven Joined The Mile High Club...Kinda | The Yak 5-6-24

37.5K3 -

4:48

4:48

unclemattscookerylessons

5 hours agoRisotto Milanese: A culinary masterpiece

31.3K8 -

41:03

41:03

Athlete & Artist Show

3 days ago3rd DEL Cup In 4 Years, Rod Brind'Amour To Seattle? And More!

29K3