Premium Only Content

Allan Fink's Mosquito Helicopter

The Mosquito is especially developed to meet the legal limit for an ultralight helicopter designation in the. As such, no pilot certificate is required to fly. But please note, that one must know how to fly a helicopter before attempting to fly the single-place Mosquito. The is an exact copy of the Mosquito, but comes with floats, a vertical stabilizer and the fuel capacity is reduced.

Although the Mosquito will float on calm water, it is not recommended that one operate on water. Depending on the water activity, mast-bumping or even a boom-strike is possible.

The Mosquito airframe is a unibody construction made entirely of high quality fiberglass in a vinylester matrix. Body and structure are the same to minimize weight and maximize structural efficiency.

The Mosquito a two cycle, two-cylinder engine with the highest power to weight ratio on the market today. This engine employs Reed Induction which yields a very flat torque curve ensuring power is delivered constantly over the required operating range. It also has a lower operating speed of 6000 rpm when compared to other engines with similar power range that typically operate at 6500 to 7000 rpm resulting in less stress on the engine and improving reliability. The complete engine package only weighs 69 pounds and comes with a 180-watt alternator that provides power to run the electrical system, which also features an electric start system.

The primary reduction is bolted directly to the engine. A centrifugal clutch on the engine crankshaft permits startup of the engine without the load of the rotor. Power is transmitted from the clutch to the driven pulley of the reduction through an cog belt, one of the highest power to weight ratio power transmission methods available. The driven pulley houses the sprage clutch which permits the rotor to overrun the engine during autorotation.

The main rotor is a semi-rigid configuration. Main rotor blades consist of an aluminum spar bonded to a wrapped aluminum sheet skin. Foam plugs at both ends prevent interior contamination and pumping losses. The tail rotor is also of a semi-rigid configuration with aluminum skin wrapped around a tube and foam plugs at either end. A 45 degree drag hinge is utilized to maintain tail rotor alignment.

The control system is unique to the Mosquito. Main rotor control is achieved from the floor mounted joystick and collective through a control mixer in the base of the main mast, then through push tubes in the mast up to the base of the swash plate. The swash plate is contained within the mast and is supported by a push tube located in the rotor shaft. Control rods on either side of the push tube transmit inputs through the rotor shaft to the control lever on top of the rotor shaft and then down to the blade pitch horns through pitch links.The tail rotor is controlled by the foot pedals through a push pull cable to an actuating lever on the tail rotor shaft.

-

9:34

9:34

amar60

6 years ago $0.01 earnedMosquito helicopter

136 -

9:34

9:34

Airspace2

6 years agoMosquito Helicopter, the smallest helicopter in the world

86 -

0:47

0:47

WGBA

6 years agoHuge mosquito

18 -

4:35

4:35

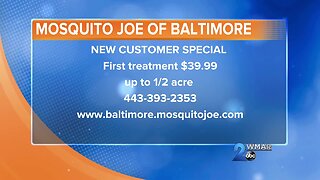

WMAR

6 years agoMosquito Joe

14 -

2:58

2:58

KERO

5 years agoBakersfield Mosquito Sprays

728 -

1:39

1:39

KERO

5 years agoBakersfield Mosquito Sprays

30 -

1:39

1:39

KERO

5 years agoBakersfield Mosquito Sprays

26 -

2:46

2:46

KERO

6 years agoUnusual Mosquito Activity

22 -

2:46

2:46

KERO

6 years agoUnusual Mosquito Activity

22 -

0:42

0:42

TJAlex

6 years agoHelicopter acrobatic

16.6K2