Premium Only Content

3D Printed Parts Are Making Fusion Energy a Reality #FusionEnergy #3DPrinting #WorldTechnology

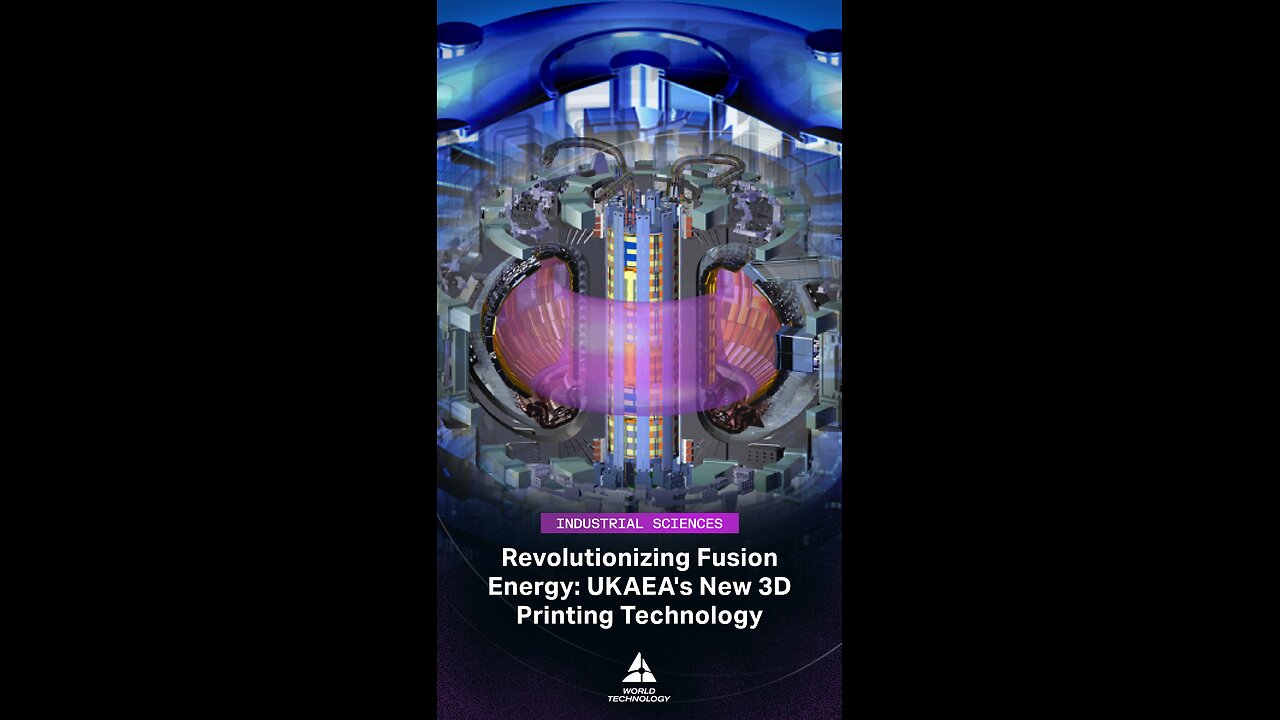

Fusion energy promises the power of the sun right here on Earth. But making it work requires extreme heat, intense magnetic fields, and materials that can survive both.

That is where Roy Marshall and the UK Atomic Energy Authority step in. They are using cutting edge 3D printing techniques like electron beam melting and selective laser melting to build custom reactor parts from tungsten, copper, and advanced steels. These materials can withstand brutal conditions and still perform.

By replacing traditional manufacturing with 3D printed precision, the UKAEA is making fusion systems cheaper, faster, and more efficient. Their work brings us closer than ever to clean, sustainable energy.

We celebrate Roy Marshall and the UKAEA team for transforming the future of energy with bold innovation.

About World Technology:

Welcome to World Technology where science meets competition. We bring together brilliant minds and innovative thinkers from around the globe to compete collaborate and celebrate advancements in Life Sciences Earth Sciences Industrial Sciences and Data Sciences.

👉 Visit us: www.worldtechnology.games

👉 Our socials on Linktree: linktr.ee/worldtechnologygames

#FusionEnergy #3DPrinting #WorldTechnology #RoyMarshall #UKAEA #CleanEnergy #AdvancedManufacturing #ElectronBeamMelting #SelectiveLaserMelting #EnergyInnovation #Tungsten #CopperAlloys #ExtremeEngineering #EnergyFuture #NuclearFusion #EngineeringBreakthrough #SustainableTech #AdditiveManufacturing #CelebrateHumanIngenuity #WorldTechnologyGames #SmartMaterials #HeatResistantMetals #ScienceAndInnovation #NextGenEnergy #FusionReactor

-

18:53

18:53

Wrestling Flashback

23 days ago $7.88 earned10 WWE Wrestlers Who Ruined Their Bodies Wrestling Too Long

14.1K4 -

LIVE

LIVE

Amarok_X

1 hour ago🟢LIVE ARC RAIDERS | TOPSIDE FOR SCRAPPY | PREMIUM CREATOR | VETERAN GAMER

218 watching -

27:03

27:03

The Kevin Trudeau Show Limitless

3 days agoThey're Not Hiding Aliens. They're Hiding This.

49.4K72 -

22:17

22:17

MetatronGaming

6 days agoI spent 7 days in the 1980s

10K7 -

LIVE

LIVE

FrizzleMcDizzle

1 hour agoGRINDING new NightReign content - COME HANG

98 watching -

26:02

26:02

Planet 3 Outdoors

28 days ago $0.74 earnedBuilding a Treehouse and Catch & Cook a Giant Fish by the River 🌧️🍳

12.3K4 -

LIVE

LIVE

Rotella Games

14 hours agoSaturday Morning Family Friendly Fortnite

102 watching -

LIVE

LIVE

Shield_PR_Gaming

2 hours ago12/06/25 | Mobius Final Fantasy Reborn & other games!? Follow me on PickAx (referral in description)

41 watching -

1:44:12

1:44:12

L1feCount3r

3 hours agoARC RAIDERS x LC: Enter the Chaos. Leave No Scrap Behind

10.5K -

LIVE

LIVE

smay2010

3 hours agoVariety Game Stream!

41 watching