Premium Only Content

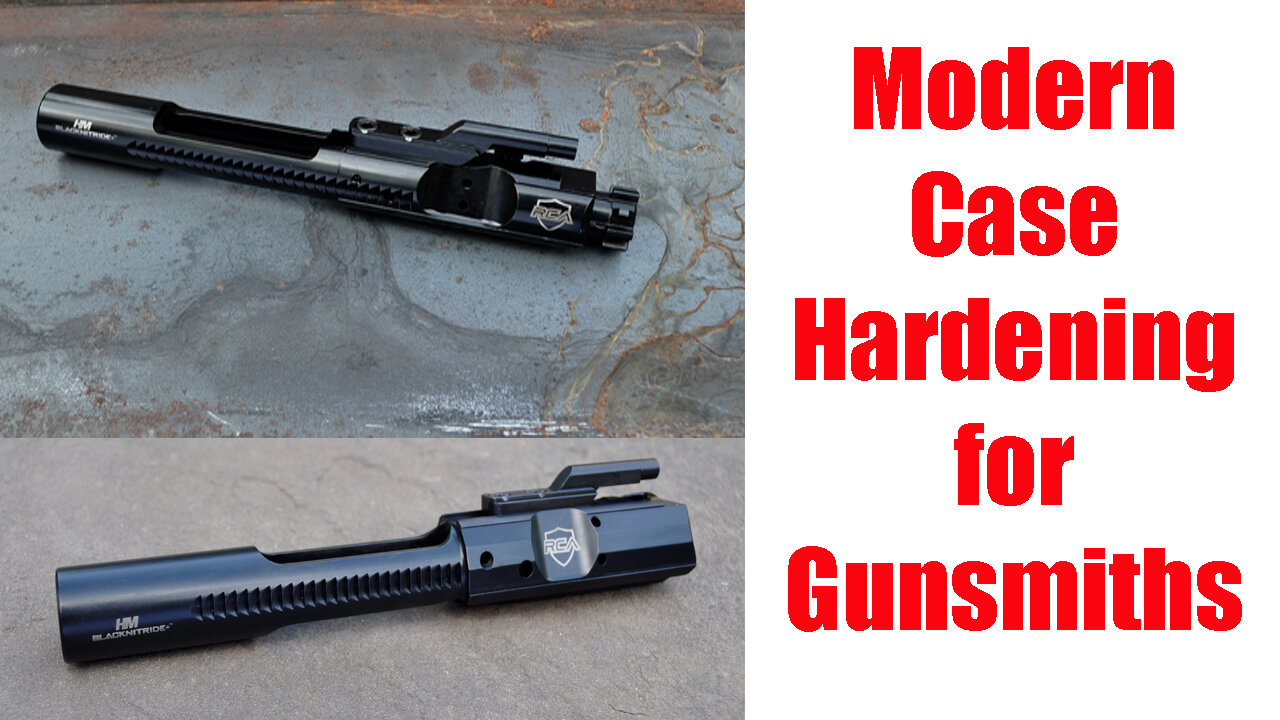

Modern Case Hardening for Gunsmiths

Article and FNC research paper:

https://firearmusernetwork.com/modern-case-hardening/

Modern Case Hardening. Finishes have advanced greatly since basic bluing. Ferritic nitrocarburizing is incredibly durable but was never aesthetically pleasing. Blacknitride+™ and ArmorTi changes that notion.

Ferritic nitrocarburizing (sometimes abbreviated FNC) is a case hardening processes that diffuses nitrogen and carbon into ferrous metals at sub-critical temperatures during a salt bath. Processing at a temperature of over 1,000°F where ferrous alloys and steel are in a ferritic phase provides advantages over other case hardening processes that occur in the hotter austenitic phase.

FNC improves surface integrity aspects by increasing corrosion and scuffing resistance as well as fatigue properties while inducing little shape distortion during the hardening process. By staying in the cooler ferritic phase and using a lower processing temperature, thermal shock is reduced and phase transitions in the steel are avoided.

The process dates back to experiments in the 1950s. Early attempts were difficult to clean and not very environmentally friendly. Degussa in Germany released their Tufftride/Tenifer process. This was commonly used for engine components in locomotives and known for its harsh wear and corrosive resistant properties.

FNC is known by a number of proprietary names, such as Tufftride, Tenifer, Melonite, Nu-Tride, and QPQ (Quench Polish Quench). These processes are commonly used on low-carbon, low-alloy steels, however they can also be used on medium and high-carbon steels. Common applications include spindles, cams, gears, dies, hydraulic piston rods, and powdered metal components.

H&M Metal Processing (Blacknitride.com, 330/745-3075) was originally founded in 1946 as a full-service heat treat factory. In 1948, the family grandfather bought an interest in the company and in the late 1980s, the factory expanded its capabilities to provide salt bath nitriding. Today, H&M is a fourth generation, family-owned company in Akron, Ohio and exclusively specializes in providing its proprietary metal surface treatment, Blacknitride+™.

Blacknitride+ is a QPQ steel hardening process tested for superior corrosion resistance, lower co-efficient of friction, and increase lubricity. With a 50,000 square foot facility staffed with 50 employees in Akron, Ohio and an additional 20,000 square foot Glendale, Arizona facility staffed with five employees, H&M maintains its own in-house metallurgical research and development testing laboratory and FFL license. Blacknitride+ is very hard, slick, and leaves and attractive finish on steel parts.

ArmorTi

Blacknitride+ is for steel parts, however, this type of surface-hardening treatment and finish is also available for titanium. Titanium is a great material for gun building as it is light and strong but the friction is bad, galling is a big problem, and there are issues with impact damage. This creates problems in applications where titanium would otherwise work well. McMillen started Akron Research and Technology (AkronRT.com, 330/745-3075) to address these issues.

Unlike other options, ArmorTi changes the metallurgy of the outer layer of the titanium by diffusing interstitial hardening elements into the surface instead of applying a new material to the outer surface of the titanium. Where traditional titanium anodizing results is an oxide finish intended to reduce galling, it fails to hold up under extreme friction and other heavy load-related conditions found in firearms and many aerospace and automotive applications.

This makes ArmorTi for titanium the equivalent of Blacknitride+ for steel. Like H&M, Akron Research and Technology offers a custom shop for gunsmiths. After making the same type of arrangements, gunsmith can have their titanium guns and parts finished with ArmorTi.

-

7:28

7:28

Firearm User Network

1 month agoMarksmanship Test: Who SHOOTS the best?

48 -

LIVE

LIVE

LFA TV

3 hours agoLFA TV ALL DAY STREAM - TUESDAY 8/26/25

6,028 watching -

1:15:15

1:15:15

JULIE GREEN MINISTRIES

3 hours agoTHE CIA HAS BEEN A GIANT IN THIS LAND THAT WILL BE TAKEN OUT

67.7K109 -

The Bubba Army

23 hours agoBURN The FLAG, Go to JAIL! - Bubba the Love Sponge® Show | 8/26/25

54.5K19 -

29:45

29:45

DeVory Darkins

17 hours ago $7.39 earnedDemocrat Governor suffers EMBARRASSING LOSS to Trump as ICE takes Garcia into custody

27.1K74 -

18:22

18:22

World2Briggs

21 hours ago $2.99 earnedThe New York Rant: Point Blank With No Fluff or BS. A Warning

19.3K7 -

42:52

42:52

The Finance Hub

15 hours ago $4.23 earnedBREAKING: ALINA HABBA JUST SHOCKED THE WORLD!

22.7K36 -

2:00:44

2:00:44

BEK TV

1 day agoTrent Loos in the Morning - 8/26/2025

23K -

12:15

12:15

Nikko Ortiz

19 hours agoMonday Gun Fails

82.3K18 -

8:19

8:19

MattMorseTV

18 hours ago $12.78 earnedTrump is ACTUALLY DOING IT.

76.5K55