Premium Only Content

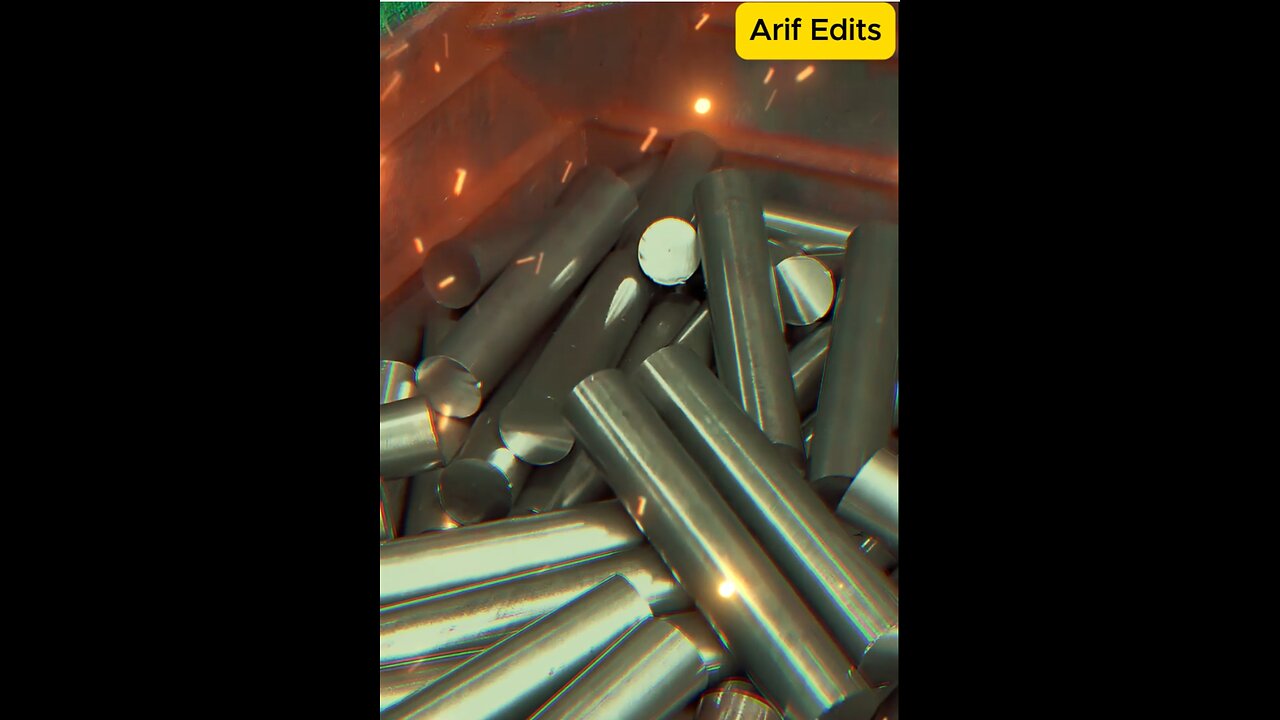

Making a bolt in Factory

The process of making a bolt in a factory involves several precise and automated steps to ensure strength, durability, and accuracy.

Material Selection: The process begins with selecting high-quality steel or other metal alloys. The chosen material is typically in the form of long rods or wire coils.

Cutting: The metal rods are cut into specific lengths based on the required bolt size. This step ensures uniformity in the final product.

Cold Forging: The cut pieces are then fed into a cold forging machine, where they are shaped under high pressure into the basic form of a bolt, including the head and shank.

Thread Rolling: A threading machine is used to roll precise threads onto the bolt's shank. This process ensures strong, accurate threads that allow for easy fastening.

Heat Treatment: To enhance the bolt's strength and durability, it undergoes heat treatment, which hardens the metal and improves its resistance to wear and tear.

Surface Coating: To prevent corrosion and improve appearance, the bolts may be coated with materials such as zinc, nickel, or black oxide.

Quality Inspection: Each bolt is inspected for accuracy, strength, and finish. This ensures that the product meets industry standards before packaging.

Packaging and Distribution: Finally, the finished bolts are sorted, packaged, and distributed to various industries, including construction, automotive, and manufacturing.

-

LIVE

LIVE

Akademiks

3 hours agoWAR IN ATLANTA Episode 5. YOUNG THUG FIRST INTERVIEW about SNITCHING, GUNNA... BREAKS DOWN CRYING!

10,396 watching -

LIVE

LIVE

SpartakusLIVE

6 hours agoVerdansk Duos w/ Nicky || Saturday Spartoons - Variety Later?!

289 watching -

LIVE

LIVE

Badlands Media

20 hours agoDevolution Power Hour Ep. 387

6,495 watching -

DVR

DVR

Man in America

10 hours agoSoaring Gold Exposes the Imminent Crash of the Old System w/ John Perez

15.7K -

LIVE

LIVE

TruthStream with Joe and Scott

10 hours agoTHOMAS AND GROK: AI, Bible decodes, The JESUS Cube live 9/6: 7pm pacific 10 pm Eastern

172 watching -

LIVE

LIVE

BlackDiamondGunsandGear

4 hours agoGet Prepped / After Hours Armory / LIVE SHOW /

93 watching -

LIVE

LIVE

Tundra Tactical

3 hours ago $0.68 earned🛑LIVE NOW!! This spits in the face of the Second Amendment.🛑

169 watching -

LIVE

LIVE

DLDAfterDark

2 hours agoIt's SHTF! Do You Have What You Need?? Let's Review Items & Priorities

112 watching -

28:58

28:58

Stephen Gardner

3 hours ago🚨Explosive allegations: Rosie O’Donnell connects Trump to Epstein scandal!?

4.54K31 -

LIVE

LIVE

SavageJayGatsby

1 day agoSpicy Saturday | Let's Play: Grounded

588 watching