Premium Only Content

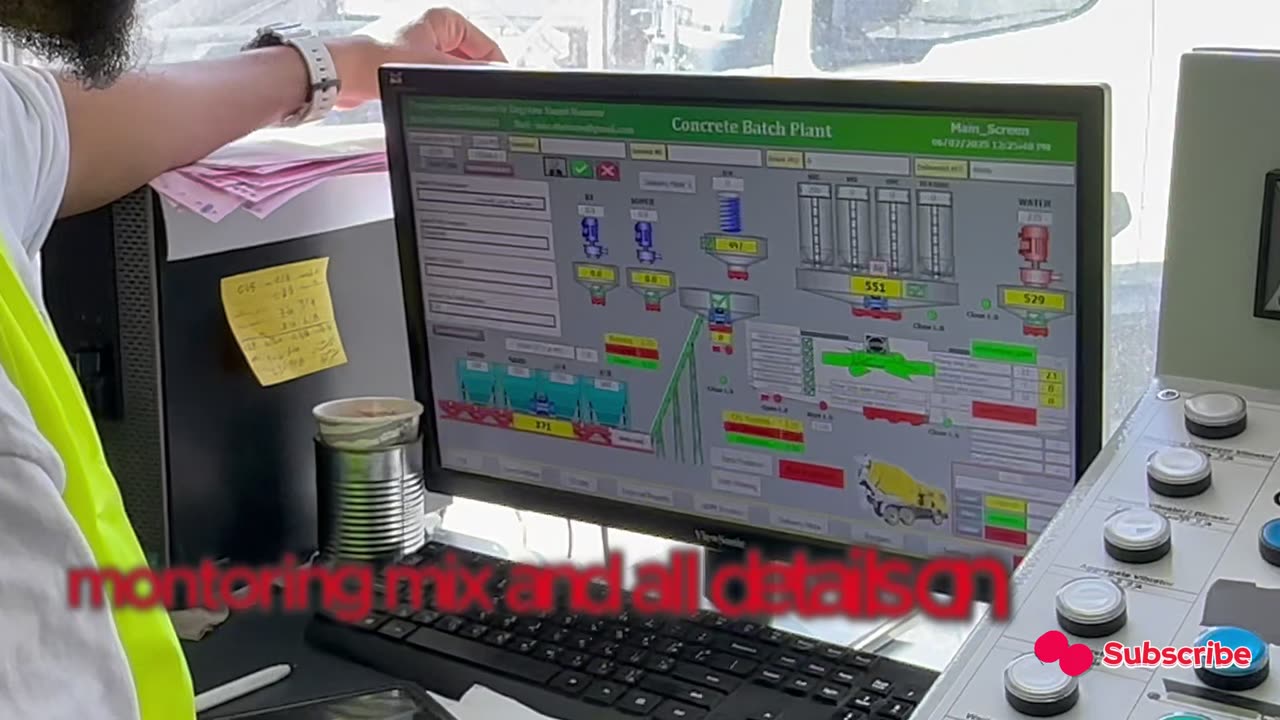

Batching Plant Tour of Control Room, Stockpile Area for Concrete Plant vlog

well-organized stockpile area is crucial for the efficient and consistent operation of a concrete batching plant, especially in a large-scale project like NEOM in Duba. This area serves as the central hub for storing all the raw materials needed for concrete production. Let's explore the key aspects of such a stockpile area:

Materials Stockpiled:

The Duba NEOM concrete plant stockpile area would likely house the following materials:

Aggregates:

Fine Aggregate (Sand): Various types of sand, potentially including dune sand, manufactured sand, or imported sand, depending on the project specifications and availability. Different gradations of sand might be stored separately.

Coarse Aggregate (Gravel/Crushed Stone): Different sizes and types of coarse aggregate, such as crushed rock (granite, limestone, basalt), gravel, or a combination. These are typically separated by size (e.g., 10mm, 20mm, 40mm) to allow for precise mix design control.

Cementitious Materials:

Cement: Different types of cement (e.g., Ordinary Portland Cement, blended cements) are stored in silos or dedicated storage areas, protected from moisture.

Supplementary Cementitious Materials (SCMs): These can include fly ash, silica fume, or slag, stored in silos or bags, depending on the material and quantity.

Admixtures: Chemical admixtures, which enhance concrete properties, are stored in liquid tanks or containers, clearly labeled and organized.

Water: A reliable water source is essential. This may involve storage tanks or access to a municipal water supply.

Other Materials: Depending on the specific concrete mixes being produced, other materials might be stored, such as fibers (steel, polypropylene), pigments, or specialized aggregates.

Stockpile Area Structure and Organization:

Designated Storage Areas: Clearly demarcated areas for each material to prevent contamination and ensure easy identification. This includes separate bays or bins for different sizes and types of aggregates.

Material Separation: Physical barriers (walls, dividers) or sufficient spacing between stockpiles to prevent mixing or contamination of different materials. This is critical for maintaining mix consistency.

Access Roads: Well-maintained access roads for trucks delivering materials and for equipment (loaders, excavators) to move materials within the stockpile area. These roads should be designed for efficient traffic flow and minimal congestion.

Drainage: Proper drainage systems to prevent water from accumulating in the stockpile area, which can affect the moisture content of aggregates and lead to environmental issues. This might involve sloping the ground, drainage ditches, or other methods.

Environmental Protection: Measures to minimize dust generation (e.g., water spraying, wind barriers), prevent runoff of materials, and control noise. This is particularly important in environmentally sensitive areas like NEOM.

Inventory Management: Systems for tracking material quantities, including visual inspection, weighing systems, or automated inventory management software. This ensures sufficient stock and avoids shortages.

Safety: Clear safety signage, designated walkways, and proper lighting to ensure the safety of workers and prevent accidents. Regular safety inspections and training are essential.

Security: Fencing, gates, and security cameras to prevent unauthorized access and theft of materials.

Equipment and Infrastructure:

Loading Equipment: Wheel loaders, excavators, or other equipment for moving and handling materials. The type and size of equipment will depend on the scale of the operation.

Conveyors: Conveyor belts might be used to transport materials from the stockpile area to the batching plant.

Weighing Systems: Weighbridges or other weighing systems to accurately measure the quantities of materials being used in the concrete mix.

Silos: Storage silos for cement and other fine materials, often equipped with weighing systems and dust control measures.

Water Tanks: Storage tanks for water used in the concrete mix.

Bins and Hoppers: Storage bins and hoppers for aggregates, designed for easy loading and unloading.

Visiting the Stockpile Area:

When visiting a stockpile area like the one in Duba NEOM, you would likely observe:

Large mounds of aggregates of different colors and sizes, neatly organized into separate piles.

Silos for cement and other fine materials.

Storage areas for admixtures and other materials.

Heavy equipment, such as loaders and excavators, moving materials around.

Dust control measures, such as water sprays or wind barriers.

Workers wearing safety gear, overseeing the operations.

Signage indicating material types, storage locations, and safety warnings.

By understanding the layout, organization, and operation of the stockpile area, you can gain a better appreciation for the complexity and scale of concrete production in a large project like NEOM.

-

LIVE

LIVE

The Bubba Army

21 hours agoICE Raid Protests SPREAD to more cities! - Bubba the Love Sponge® Show | 6/12/25

6,011 watching -

14:26

14:26

Degenerate Jay

1 day agoShould Star Wars Be Done With Luke Skywalker?

2152 -

44:01

44:01

Esports Awards

17 hours agoFrom Football Fields to Esports Arenas: The Journey of Sc0utOP | Origins Podcast #11

1.15K1 -

UPCOMING

UPCOMING

BEK TV

16 hours agoTrent Loos in the Morning 6/12/2025

2.02K -

12:29

12:29

Clownfish TV

19 hours agoTerry Moran is TOAST.

10.2K13 -

5:25

5:25

The Shannon Joy Show

13 hours ago🎭UN's Puppets & the Bio-Terror Script - Event 201 Was Just the Beginning🔥

4.91K5 -

LIVE

LIVE

PudgeTV

1 hour ago🟠 Mafia II: Definitive Edition | Live Playthrough | Gaming on Rumble

310 watching -

27:21

27:21

ArturRehi

19 hours agoNATO's NEW Tank Powerhouse: Poland Buys 6 Billion $ of Tanks K2s from South Korea! Ukraine Update

5.05K4 -

5:38

5:38

DropItLikeItsScott

21 hours ago $0.90 earnedCheck out the New BREEK ARMS 3QD LOK System. It is EPIC

4.65K1 -

LIVE

LIVE

Lofi Girl

2 years agolofi hip hop radio 📚 - beats to relax/study to

977 watching