Premium Only Content

Rigger Interview Questions _ Answers (India _ Gulf) _ Rigger Job Interview Questions _ Answers

Here’s a comprehensive list of **rigger interview questions and answers** tailored for job interviews in **India** and the **Gulf countries**, where safety standards and technical expertise are crucial.

---

## **General Rigger Interview Questions and Answers**

### **1. What is a rigger's primary role?**

**Answer:**

- A rigger is responsible for setting up, attaching, and securing loads to cranes or lifting equipment for safe transportation or lifting operations. They ensure all rigging equipment is properly inspected and used according to safety guidelines.

---

### **2. What are the key tools and equipment used by a rigger?**

**Answer:**

- Chain slings

- Wire rope slings

- Shackles

- Hooks

- Turnbuckles

- Spreader bars

- Hoists

- Load binders

---

### **3. What are the steps you take to inspect rigging equipment?**

**Answer:**

1. Check for visible damage, such as cracks, cuts, or wear.

2. Inspect slings for broken wires, corrosion, or elongation.

3. Verify identification tags are intact and legible.

4. Ensure hooks have working safety latches and no deformation.

5. Test the functionality of load limiters and safety mechanisms.

---

### **4. What is the importance of load charts in lifting operations?**

**Answer:**

- Load charts provide information on the crane's maximum lifting capacity at different boom lengths, angles, and radii. It ensures the load does not exceed safe limits, preventing overloading and accidents.

---

### **5. How do you calculate the sling angle factor?**

**Answer:**

- **Formula: Sling Angle Factor = 1 / cos(θ)**

- Where **θ** is the angle between the sling and the horizontal plane.

- Example: If the sling angle is 45°, the factor is 1 / cos(45°) = 1.414.

- Use this factor to determine the increased tension in the sling.

---

### **6. What is the difference between a shackle and a hook?**

**Answer:**

- **Shackle:**

- A U-shaped device with a pin or bolt used to connect slings, ropes, or chains.

- **Hook:**

- A curved device used to secure and lift loads, typically with a safety latch.

---

### **7. How do you ensure the stability of a load during lifting?**

**Answer:**

- Use proper rigging techniques to center the load.

- Attach slings symmetrically to distribute weight evenly.

- Keep the load balanced and close to the ground while lifting.

- Use taglines to control swinging and prevent rotation.

---

### **8. What are taglines, and why are they used?**

**Answer:**

- Taglines are ropes attached to a load to control its movement during lifting. They prevent the load from swinging, rotating, or colliding with nearby objects.

---

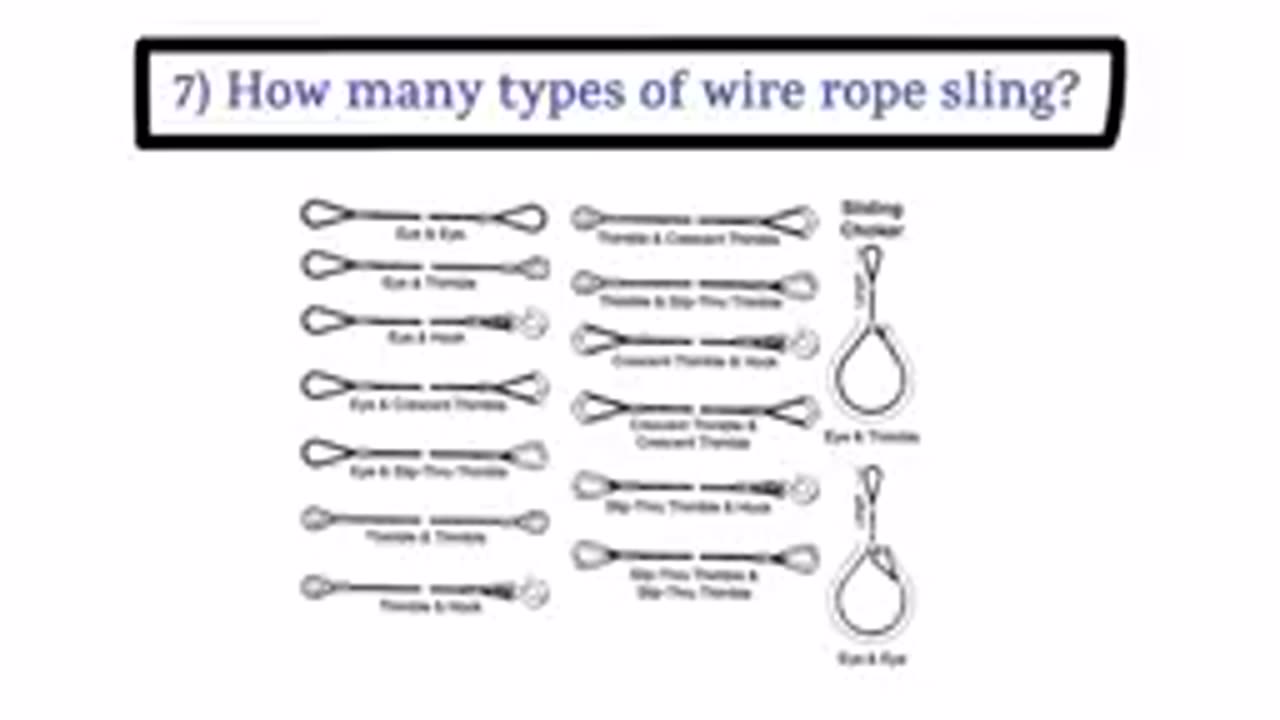

### **9. What are the different types of slings?**

**Answer:**

1. **Wire Rope Slings:**

- Used for heavy loads and high-temperature environments.

2. **Chain Slings:**

- Durable and resistant to abrasion, ideal for rugged conditions.

3. **Web Slings:**

- Lightweight and flexible, suitable for delicate loads.

4. **Round Slings:**

- Made from synthetic fibers, used for odd-shaped or fragile loads.

---

### **10. What is the breaking strength of rigging equipment?**

**Answer:**

- The breaking strength is the maximum load that rigging equipment can handle before failure. It’s critical to stay well below this limit and adhere to the **Working Load Limit (WLL)**, which includes a safety factor.

---

### **11. How do you handle an emergency during lifting operations?**

**Answer:**

- Stop all operations immediately.

- Inform the supervisor or safety officer.

- Evacuate the area if necessary.

- Follow site-specific emergency procedures and ensure the situation is under control before resuming work.

---

### **12. What are common rigging safety hazards?**

**Answer:**

- Overloading equipment.

- Using damaged or improperly inspected rigging gear.

- Incorrect sling angles leading to excessive tension.

- Load imbalance or improper securing.

- Working near energized power lines.

---

### **13. What is the difference between SWL and WLL?**

**Answer:**

- **SWL (Safe Working Load):**

- The maximum load equipment can handle under normal conditions.

- **WLL (Working Load Limit):**

- The maximum load equipment can safely lift, accounting for safety factors.

---

### **14. What is a load moment indicator (LMI)?**

**Answer:**

- An LMI is a device on cranes that monitors the load weight, boom angle, and radius. It alerts operators if the load exceeds safe limits to prevent overloading.

---

### **15. What should you check before starting lifting operations?**

**Answer:**

1. Inspect rigging equipment for damage.

2. Verify the crane's load chart and capacity.

3. Check ground stability and crane outriggers.

4. Ensure clear communication between the operator and rigging team.

5. Identify potential hazards like overhead obstacles or power lines.

---

### **16. How do you maintain communication during lifting operations?**

**Answer:**

- Use standard hand signals or two-way radios.

- Establish clear communication protocols with the crane operator.

- Assign a designated signaler to prevent confusion.

---

### **17. What does a rigger's hand signal for "Stop" look like?**

**Answer:**

- Extend one arm horizontally and wave it back and forth to signal the crane operator to stop all movements immediately.

---

### **18. What is the safety factor for rigging equipment?**

**Answer:**

- The safety factor typically ranges between 4:1 and 6:1, depending on the type of equipment and regulations.

---

### **19. What is a critical lift, and how do you handle it?**

**Answer:**

- A critical lift involves loads that are:

- Near the crane's maximum capacity.

- Over hazardous areas like people or structures.

- Non-standard or complex.

- **Handling Steps:**

- Conduct a detailed risk assessment.

- Prepare a lifting plan approved by a competent authority.

- Use additional precautions, such as backup slings and supervisors.

---

### **20. What certifications are required for riggers in India and the Gulf?**

**Answer:**

- **India:**

- Certificate of training from an accredited institution (e.g., NSDC or equivalent).

- **Gulf:**

- Certifications like **Third Party Rigger Certification** (TUV, Lloyd’s, or DNV).

- Compliance with OSHA or LOLER standards is often required.

---

Would you like a printable version, mock interview simulation, or more technical questions?

-

LIVE

LIVE

Timcast

1 hour agoBomb DETONATED At Harvard, Attacks On Ice Agents SKYROCKET

26,695 watching -

1:55:31

1:55:31

Steven Crowder

3 hours agoTucker Carlson & MAGA: Everyone is Missing the Point

235K194 -

1:11:22

1:11:22

The Rubin Report

2 hours agoWatch Joe Rogan’s Face as Elon Musk Exposes How Dems Are Cheating in Plain Sight

23.4K32 -

1:01:07

1:01:07

VINCE

4 hours agoThe Walls Are Closing In On The Deep State | Episode 160 - 11/03/25

183K121 -

LIVE

LIVE

LFA TV

19 hours agoLIVE & BREAKING NEWS! | MONDAY 11/3/25

3,688 watching -

1:31:18

1:31:18

Graham Allen

4 hours agoErika Fights Back: Vows To EXPOSE TRUTH & DEMANDS Trial Goes Public!! Left Says Her Grief Is FAKE!

130K79 -

2:08:47

2:08:47

Badlands Media

9 hours agoBadlands Daily: November 3, 2025 – Tariff Wars, SNAP Panic & Brennan Gets Confronted

53.9K14 -

2:59:32

2:59:32

Wendy Bell Radio

8 hours agoThings Will Get Worse Before They Get Better

78K97 -

1:18:28

1:18:28

The Big Mig™

4 hours agoICE Will Use Private Bounty Hunters, LFG

20.1K9 -

1:08:17

1:08:17

Chad Prather

11 hours agoHow to Get Along With People You Don’t Even Like (Most of the Time)

113K31