Premium Only Content

Crane Inspection - How To Inspect Crane - Crane Inspection Important Points_2

### **Crane Inspection: Important Points and Guidelines**

This guide covers the key steps and critical points to consider during a crane inspection, ensuring safe and efficient crane operations.

---

## **1. Types of Crane Inspections**

1. **Pre-Operational Inspections (Daily/Before Use):**

- Conducted at the start of each shift to identify immediate safety hazards.

2. **Periodic Inspections:**

- Performed monthly or quarterly based on usage and regulatory requirements.

3. **Annual Inspections:**

- Comprehensive checks carried out by certified inspectors.

---

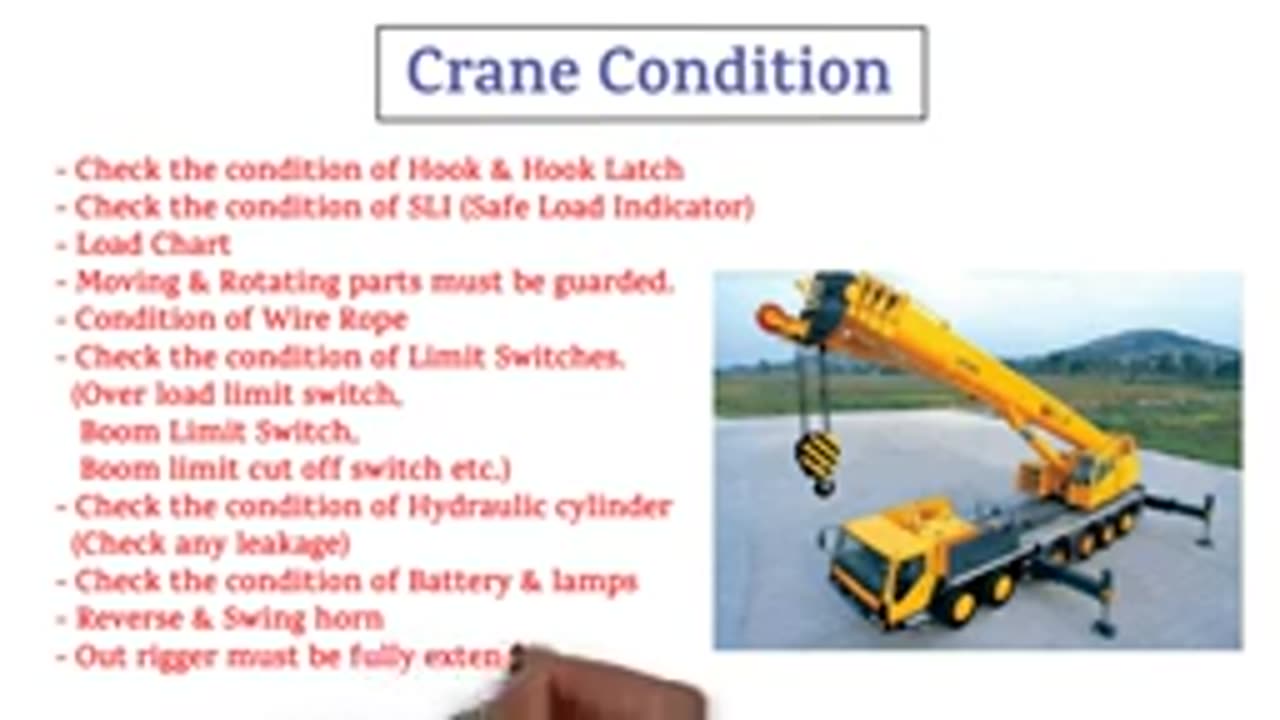

## **2. Key Crane Inspection Points**

### **2.1. Structural Components**

- **Boom and Jib:**

- Check for cracks, bends, corrosion, or dents.

- Ensure proper alignment and smooth operation.

- **Frame and Chassis:**

- Inspect for structural damage, rust, or missing bolts.

- Confirm that outriggers extend and lock securely.

---

### **2.2. Load Handling Equipment**

- **Hooks:**

- Inspect for cracks, deformation, or wear.

- Ensure the safety latch is functional.

- **Wire Ropes:**

- Look for kinks, fraying, broken wires, or corrosion.

- Check for proper spooling on the drum without overlapping.

- **Sheaves:**

- Ensure they are free of cracks and turn smoothly.

- Inspect grooves for wear and proper alignment.

---

### **2.3. Hydraulic Systems**

- **Hoses and Connections:**

- Check for leaks, cracks, or bulges.

- Ensure secure connections at fittings.

- **Cylinders:**

- Inspect for dents or leaks around seals.

- Test for smooth operation during boom movement.

- **Fluid Levels:**

- Verify hydraulic oil levels are within acceptable limits.

---

### **2.4. Mechanical Systems**

- **Hoist Mechanism:**

- Ensure the hoist drum operates smoothly without jerking.

- Inspect brake systems for wear and proper functioning.

- **Slewing Ring (Rotating Mechanism):**

- Check for cracks, missing bolts, and smooth rotation.

- **Gearboxes and Bearings:**

- Look for signs of overheating, noise, or wear.

- Confirm lubrication levels are adequate.

---

### **2.5. Electrical Systems**

- **Control Panel:**

- Test all switches, buttons, and joysticks for functionality.

- **Warning Alarms and Indicators:**

- Verify operational status of alarms, lights, and load moment indicators (LMI).

- **Wiring:**

- Check for exposed or frayed wires, loose connections, or overheating.

---

### **2.6. Safety Systems**

- **Anti-Two-Block Device:**

- Test to ensure it prevents the hook block from contacting the boom tip.

- **Emergency Stop:**

- Confirm the emergency stop button halts all operations immediately.

- **Load Limiters:**

- Ensure the crane stops lifting when the load exceeds its rated capacity.

---

### **2.7. Mobility and Stability**

- **Tires or Tracks:**

- Inspect for wear, proper inflation, and alignment.

- For tracked cranes, check for loose or damaged tracks.

- **Outriggers and Pads:**

- Ensure full extension and proper locking.

- Verify pads or mats are used on soft or uneven surfaces.

- **Counterweights:**

- Check for secure attachment and proper weight according to the load chart.

---

## **3. General Inspection Guidelines**

1. **Documentation:**

- Verify the availability of load charts, operator manuals, and previous inspection records.

2. **Environment:**

- Ensure the crane operates on stable, level ground.

- Check for overhead obstacles (e.g., power lines, structures).

3. **Tagging:**

- Tag the crane as "Out of Service" if defects are identified.

- Do not operate until all issues are repaired and re-inspected.

---

## **4. Inspection Tools and Equipment**

- Flashlight for detailed visual inspections.

- Measuring tools (e.g., calipers) for wear assessment.

- Torque wrench for verifying bolt tightness.

- Lubrication equipment for maintaining moving parts.

---

## **5. Recordkeeping**

- Maintain detailed logs for:

- Inspection dates.

- Inspector’s name and qualifications.

- Observations and corrective actions taken.

- Repairs or replacements performed.

---

## **6. Common Issues to Watch For**

1. **Structural Damage:**

- Cracks, bends, or corrosion in load-bearing parts.

2. **Hydraulic Leaks:**

- Fluid seeping from hoses or cylinders.

3. **Wire Rope Wear:**

- Broken strands, kinks, or flattened sections.

4. **Operational Malfunctions:**

- Jerky movements, excessive noise, or slow response times.

---

## **7. Frequency of Inspections**

- **Frequent Use:**

- Daily or before each shift for cranes in constant operation.

- **Moderate Use:**

- Weekly or biweekly for cranes used occasionally.

- **Regulatory Compliance:**

- Follow local, national, and manufacturer guidelines for inspection intervals.

---

## **8. Safety Precautions During Inspection**

- Use personal protective equipment (PPE) such as gloves, helmets, and safety boots.

- Block or immobilize moving parts before inspection.

- Avoid working under suspended loads.

---

### **End of Guide**

Would you like help preparing a detailed checklist or visual aids for crane inspections?

-

LIVE

LIVE

EXPBLESS

48 minutes agoArena Breakout (This Game Is Hard But Fun) How Much Can We Make Today? #RumbleGaming

17 watching -

4:40

4:40

GritsGG

15 hours agoTwo Easter Eggs on Call of Duty Warzone!

27.5K1 -

2:08:19

2:08:19

Side Scrollers Podcast

22 hours agoNetflix Execs to TESTIFY Over LGBTQ Agenda + IGN DESTROYS Xbox Game Pass + More | Side Scrollers

67.3K18 -

5:08:55

5:08:55

Dr Disrespect

20 hours ago🔴LIVE - DR DISRESPECT - BABY STEPS - THE VERY VERY LAST CHAPTER

142K17 -

10:28

10:28

BlabberingCollector

16 hours agoAsk Blabs, Episode 5 | Answering Your Wizarding World Related Questions

19K1 -

18:09

18:09

Forrest Galante

5 days agoI Survived 24 Hours In The World's Deadliest Jungle

202K32 -

LIVE

LIVE

Lofi Girl

2 years agoSynthwave Radio 🌌 - beats to chill/game to

263 watching -

2:15:09

2:15:09

Badlands Media

20 hours agoOnlyLands Ep. 27: Power Hour Hangover, Trump’s Wartime Shift, and Portland in Flames

131K31 -

22:21

22:21

DeVory Darkins

10 hours ago $21.73 earnedRioters attack Portland ICE Facility as Democrats make shocking admission

35.9K136 -

2:06:06

2:06:06

TimcastIRL

12 hours agoTrump DOJ Announces INTERVENTION In Portland Over Nick Sortor Arrest | Timcast IRL

255K430