Premium Only Content

HACCP for a specific proces

### **HACCP Explained: Food Safety**

**HACCP** (Hazard Analysis and Critical Control Points) is a systematic approach to food safety that identifies, evaluates, and controls hazards that could compromise food safety. It ensures food safety throughout the production process—from raw materials to finished products—by focusing on prevention rather than relying solely on end-product testing.

HACCP is widely used in the food industry to comply with food safety regulations and protect public health.

---

### **The Seven HACCP Principles**

#### **1. Conduct a Hazard Analysis**

- **Objective:** Identify potential biological, chemical, or physical hazards that could occur at various stages of food production.

- **Steps:**

- Evaluate the entire process, from raw materials to delivery.

- List potential hazards (e.g., contamination, improper cooking, foreign objects).

- Determine how these hazards can be prevented, eliminated, or reduced.

---

#### **2. Determine Critical Control Points (CCPs)**

- **Objective:** Identify specific points in the process where control is essential to prevent or reduce a food safety hazard.

- **Examples of CCPs:**

- Cooking temperatures to kill bacteria.

- Storage conditions to prevent spoilage.

- Metal detection to ensure no physical contaminants.

---

#### **3. Establish Critical Limits**

- **Objective:** Define acceptable thresholds at each CCP to ensure food safety.

- **Examples of Critical Limits:**

- Minimum internal cooking temperature: 165°F (74°C) for poultry.

- Maximum refrigeration temperature: 40°F (4°C).

- pH levels or moisture levels in certain products.

---

#### **4. Establish Monitoring Procedures**

- **Objective:** Implement procedures to consistently monitor CCPs and ensure they stay within critical limits.

- **Examples of Monitoring:**

- Using thermometers to check cooking temperatures.

- Conducting regular pH tests.

- Logging refrigeration temperatures daily.

---

#### **5. Establish Corrective Actions**

- **Objective:** Define what steps to take if a CCP exceeds its critical limits.

- **Examples of Corrective Actions:**

- Re-cooking or discarding undercooked food.

- Repairing faulty refrigeration equipment.

- Stopping production until the issue is resolved.

---

#### **6. Establish Verification Procedures**

- **Objective:** Ensure the HACCP plan is working effectively and consistently.

- **Steps:**

- Review monitoring records and corrective actions regularly.

- Perform periodic audits and inspections.

- Validate that critical limits and CCPs are appropriate.

---

#### **7. Establish Record-Keeping and Documentation**

- **Objective:** Maintain accurate records to demonstrate compliance with the HACCP plan.

- **Examples of Records:**

- Hazard analyses and identified CCPs.

- Monitoring logs (e.g., temperature charts).

- Corrective action reports.

- Verification and audit results.

---

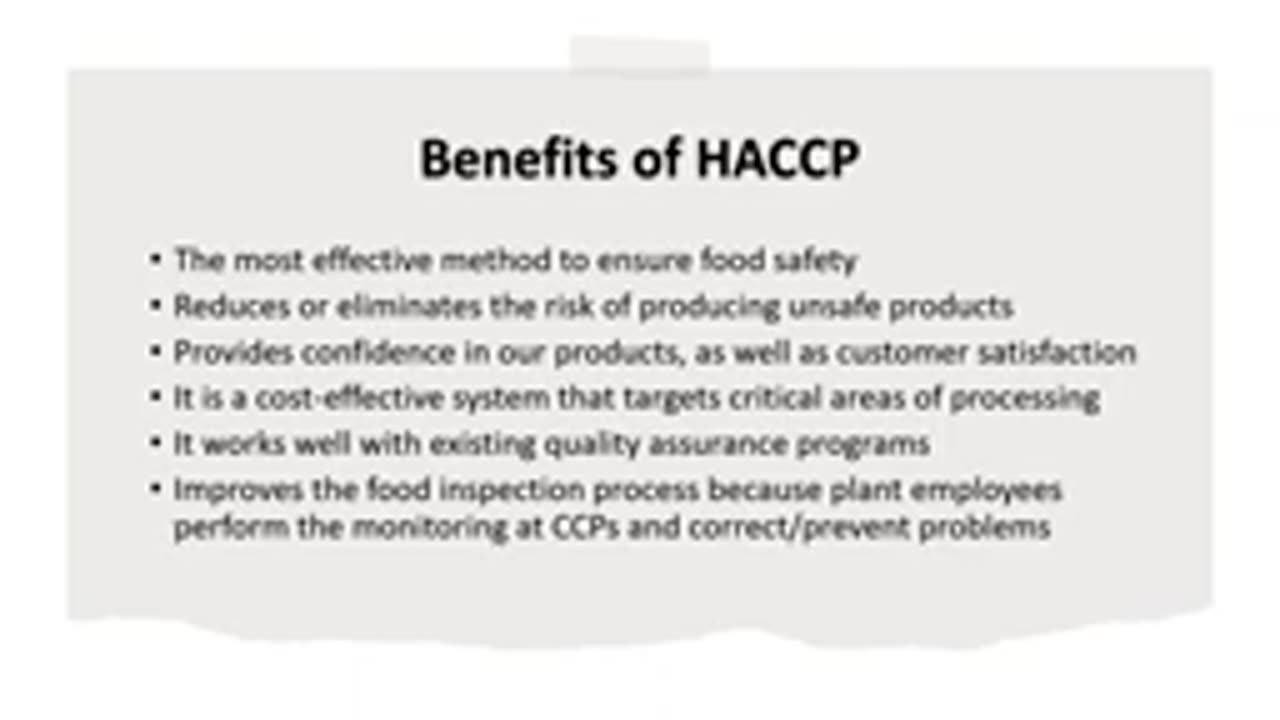

### **Why HACCP is Important**

- Prevents foodborne illnesses by addressing potential hazards proactively.

- Helps businesses comply with legal and regulatory requirements.

- Builds consumer trust by ensuring safe, high-quality food products.

Would you like to explore any of these principles in more detail or learn how to implement HACCP for a specific process?

-

1:31:40

1:31:40

Adam Does Movies

20 hours agoThe Best & Worst Christmas Movies! - LIVE!

41.9K5 -

58:10

58:10

Kimberly Guilfoyle

22 hours agoAmerica is Back & The Future is Bright: A Year in Review | Ep. 183

153K66 -

3:03:27

3:03:27

vivafrei

1 day agoEp. 242: Barnes is BACK AGAIN! Trump, Fani, J6, RFK, Chip Roy, USS Liberty AND MORE! Viva & Barnes

233K231 -

2:05:48

2:05:48

2 MIKES LIVE

3 hours agoTHE MIKE SCHWARTZ SHOW with DR. MICHAEL J SCHWARTZ 12-24-2024

15.2K1 -

1:14:17

1:14:17

MTNTOUGH Fitness Lab

1 day agoNavy SEAL Dom Raso: The Cold, Hard Truth About Modern Brotherhood | MTNPOD #96

11.9K1 -

43:42

43:42

Dad Dojo Podcast

19 hours agoEP14: Every Girl Dad's Biggest Fear and How To Prevent It

7.9K -

55:06

55:06

Bek Lover Podcast

12 hours agoWill Trump Pull Off A Miracle? Other Strange News Podcast...

6.67K4 -

55:53

55:53

PMG

1 day ago $0.01 earned"Hannah Faulkner and Courtney Reed | BEHIND THE LENS OF A TRUMP PHOTOGRAPHER"

5.59K -

8:09:50

8:09:50

Dr Disrespect

1 day ago🔴LIVE - DR DISRESPECT - MARVEL RIVALS - GOLD VANGUARD

225K37 -

1:15:00

1:15:00

Awaken With JP

1 day agoMerry Christmas NOT Happy Holidays! Special - LIES Ep 71

310K253