Premium Only Content

Fall Prevention and Protection - Construction Worksite Safety_2

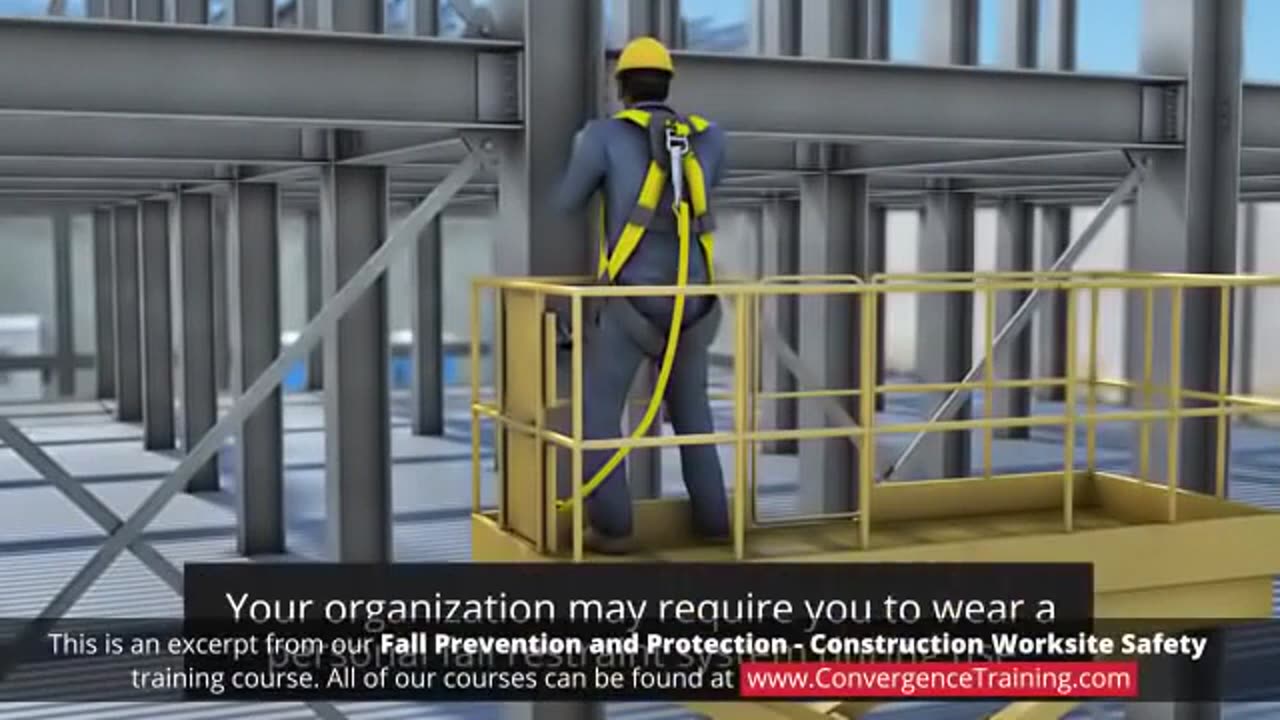

**Fall Prevention and Protection on Construction Worksites** is a critical component of construction site safety, as falls are one of the leading causes of injury and death in the industry. The goal is to prevent falls from happening and protect workers if a fall occurs. Here’s an overview of effective strategies for fall prevention and protection:

### **1. Fall Prevention:**

**Fall prevention** focuses on eliminating the risk of a fall before it happens. This involves the use of safety systems and practices designed to keep workers from getting into dangerous situations where a fall could occur.

#### **a. Use of Guardrails and Barriers:**

- Guardrails, toe boards, and barriers should be installed on all open edges, platforms, and walking/working surfaces where workers are at risk of falling.

- These safety devices should meet OSHA (Occupational Safety and Health Administration) standards for height and strength.

#### **b. Safe Work Practices:**

- Workers should be trained to recognize fall hazards and follow safe practices to avoid risky situations, such as using ladders or scaffolding safely, not leaning over edges, and maintaining a three-point stance when climbing.

- Always use personal protective equipment (PPE) correctly, and ensure it fits well and functions properly.

#### **c. Safe Access and Egress:**

- Workers should have access to safe means of entering and exiting elevated work areas, such as stairs, ladders, or ramps.

- Avoid using makeshift or unapproved means of access like boxes or scaffolding materials.

#### **d. Fall Hazard Assessment:**

- Conduct a thorough hazard assessment of the worksite to identify potential fall hazards, such as unprotected edges, holes, and elevated platforms.

- Implement engineering controls, such as eliminating unprotected edges or adding proper walkways and barriers.

### **2. Fall Protection:**

When fall prevention measures cannot fully eliminate the risk, **fall protection** must be used to minimize the severity of falls and injuries if they occur.

#### **a. Personal Fall Arrest Systems (PFAS):**

- **Harnesses and Lanyards**: Workers should wear fall arrest harnesses with appropriate lanyards or lifelines when working at heights where fall hazards cannot be eliminated. These systems arrest the fall, preventing a worker from hitting the ground or other objects.

- **Anchorage Points**: Secure and reliable anchorage points should be provided for the fall arrest systems to ensure they function effectively in stopping a fall.

- **Shock-Absorbing Components**: Lanyards should have shock-absorbing components to reduce the impact force on the worker during a fall.

#### **b. Safety Nets:**

- Safety nets should be used under elevated work areas where fall protection is required but not feasible through other means. These nets catch workers if they fall and prevent serious injuries.

- Nets should be placed as close to the working surface as possible, and the mesh size should be small enough to catch debris and prevent workers from falling through.

#### **c. Scaffolding:**

- **Scaffold Guardrails**: Scaffolds must have guardrails, midrails, and toe boards to prevent falls. Ensure scaffolding is erected and dismantled by qualified personnel, and regularly inspect scaffolding for structural integrity.

- **Secure Platforms**: Work platforms on scaffolds should be level and secure to avoid shifting, tipping, or collapse.

#### **d. Ladders:**

- Ladders must be stable and of the correct type and height for the task. Workers should always maintain three points of contact (two hands and one foot or two feet and one hand) when climbing or descending.

- Extension ladders should be placed at a 4:1 ratio (base to height) to prevent them from tipping.

#### **e. Elevated Work Platforms (EWPs):**

- EWPs such as aerial lifts or scissor lifts should be equipped with fall protection devices (guardrails, restraining devices) and should be used following safe operating procedures.

- Ensure that operators are properly trained and that the equipment is inspected before use.

### **3. Training and Education:**

- **Worker Training**: All workers should be trained in recognizing fall hazards, using fall protection systems properly, and understanding the importance of personal protective equipment. This includes proper use of harnesses, fall arrest systems, ladders, and scaffolds.

- **Supervisory Training**: Supervisors should be trained to identify fall hazards, ensure proper safety measures are in place, and enforce safety protocols.

### **4. Inspections and Maintenance:**

- **Routine Inspections**: Conduct regular inspections of fall protection systems, such as harnesses, lanyards, guardrails, and scaffolds, to ensure they are in good condition.

- **Equipment Maintenance**: Maintain all fall protection equipment according to the manufacturer’s guidelines. Any equipment that is worn, damaged, or defective should be replaced immediately.

### **5. Fall Protection Plans:**

- A **Fall Protection Plan** should be developed for each job site that identifies specific fall hazards and outlines the safety measures to prevent falls. This plan should include:

- Hazard assessments

- Safe work procedures

- Selection of appropriate fall protection systems

- Training requirements

- Emergency procedures in case of a fall.

### Conclusion:

Fall prevention and protection are essential to ensuring a safe worksite for construction workers. By using appropriate protective systems, maintaining proper equipment, and following safe work practices, the risk of falls can be significantly reduced. Regular training, hazard assessments, and adherence to safety standards are crucial in achieving a fall-free work environment.

-

2:04:11

2:04:11

Melonie Mac

10 hours agoGo Boom Live Ep 32! Soul Reaver Remastered!

56.1K10 -

39:11

39:11

Sarah Westall

8 hours agoDigital Slavery and Playing with Fire: Money, Banking, and the Federal Reserve w/ Tom DiLorenzo

65.6K8 -

1:38:38

1:38:38

2 MIKES LIVE

12 hours ago2 MIKES LIVE #157 ILLEGALS, PROTESTORS AND DRONES!

44.7K1 -

1:01:03

1:01:03

LFA TV

1 day agoTHE LATEST SPENDING BILL IS AN ABOMINATION! | UNGOVERNED 12.18.24 5pm EST

46.1K48 -

1:43:34

1:43:34

Redacted News

12 hours agoBREAKING! WARMONGERS PUSHING TRUMP TO LAUNCH PRE-EMPTIVE WAR WITH IRAN | Redacted News

159K282 -

1:00:26

1:00:26

Candace Show Podcast

11 hours agoPiers Morgan x Candace Owens | Candace Ep 123

100K269 -

2:06:51

2:06:51

Darkhorse Podcast

14 hours agoFollow the White Rabbit(s): The 256th Evolutionary Lens with Bret Weinstein and Heather Heying

67.4K31 -

3:08:08

3:08:08

Scammer Payback

12 hours agoCalling Scammer Live

39.3K3 -

1:21:25

1:21:25

Mally_Mouse

15 hours agoLet's Yap About It - LIVE!

87K10 -

5:35

5:35

Cooking with Gruel

1 day agoMaking Fresh Salted Caramel

70K7