Premium Only Content

The Hidden Engineering of Mount Rushmore

Mount Rushmore, known for its iconic carvings of four U.S. presidents, is not only a remarkable artistic achievement but also a feat of hidden engineering. The massive sculpture, located in South Dakota, required innovative techniques and careful planning to overcome the challenges of working on a granite mountainside.

---

### **Key Engineering Features**

#### **1. Sculpting Granite**

- **Material Challenges:** Granite is an extremely hard and durable rock, which posed significant difficulties for carving. The workers used dynamite for rough shaping, removing nearly 90% of the rock, followed by pneumatic drills and hand tools for finer details.

- **Precision in Dynamite Use:** Engineers and sculptors calculated explosive charges with incredible precision to avoid damaging the intricate parts of the sculptures.

---

#### **2. Stability and Safety**

- **Natural Cracks and Weaknesses:** The granite mountain contains natural fissures. Engineers reinforced vulnerable sections with bolts and concrete to prevent cracking or collapse.

- **Drainage Systems:** Channels were carved to direct water away from the carvings, reducing erosion and weathering effects.

- **Rock Testing:** The team conducted extensive surveys to ensure the granite could support the carvings and withstand the region's freeze-thaw weather cycles.

---

#### **3. Scaling the Carvings**

- **Proportional Accuracy:** A pointing machine, an innovative device for its time, was used to transfer the design from a scale model to the mountain. This ensured each feature was proportionally accurate when magnified to the massive scale.

- **Flexible Design Changes:** Original plans included full torsos of the presidents, but due to budget constraints and rock quality issues, the design was scaled back to focus on the faces.

---

#### **4. Labor and Logistics**

- **Innovative Safety Measures:** Workers used harnesses and scaffolding suspended from the mountain. Despite the inherent dangers, no lives were lost during construction.

- **Power Generation:** Engineers installed an on-site power system to run pneumatic drills and other equipment, a significant challenge in the remote Black Hills.

---

#### **5. Preservation Engineering**

- **Sealing Cracks:** Modern preservation efforts involve sealing cracks with silicone caulking to protect the carvings from moisture intrusion.

- **Laser Scanning:** Engineers and conservationists use 3D laser scanning to monitor wear and tear, ensuring the sculpture's longevity.

---

### **Legacy of Engineering**

The hidden engineering of Mount Rushmore ensured that it would not only be an awe-inspiring piece of art but also a lasting monument. Its construction pushed the boundaries of engineering and sculptural techniques of its time, leaving behind lessons in resilience, precision, and innovation. Today, Mount Rushmore stands as a testament to the collaboration of art and engineering on a monumental scale.

-

LIVE

LIVE

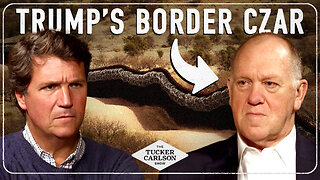

Tucker Carlson

1 hour agoTom Homan’s Plan to Destroy the Cartel Empire, End Child Trafficking, and Secure the Border for Good

7,678 watching -

1:06:28

1:06:28

Russell Brand

2 hours agoWho Ordered the Hit on Russia’s General Krylov? - SF516

35.1K29 -

LIVE

LIVE

The Charlie Kirk Show

1 hour agoThe CR Quagmire + An Hour of PBD + Catholic in Hollywood | Davis, Patrick Bet David, Rep. Burlison

7,533 watching -

LIVE

LIVE

Grant Stinchfield

1 hour agoDon't Focus on the Drones... Focus on the Mysterious Floating Orbs!

579 watching -

LIVE

LIVE

The Dana Show with Dana Loesch

1 hour agoSPENDING BATTLE COUNTDOWN | The Dana Show LIVE On Rumble!

526 watching -

59:38

59:38

The Dan Bongino Show

3 hours agoThings Have Changed, It's Trump's GOP Now (Ep. 2390) - 12/18/2024

449K899 -

LIVE

LIVE

Viss

1 hour ago🔴LIVE - Is Delta Force the Best Casual Extraction Shooter? - Delta Force

244 watching -

53:22

53:22

The Rubin Report

2 hours agoElon Musk's Major Announcement Reveals His Next Target & It's Huge

27.9K25 -

2:15:29

2:15:29

Steven Crowder

4 hours ago🔴 The True Cost of Fat Pride: How It's Destroying America

226K133 -

2:24:25

2:24:25

Matt Kohrs

11 hours agoFed's FOMC Decision Day Chaos || The MK Show

66K3