Premium Only Content

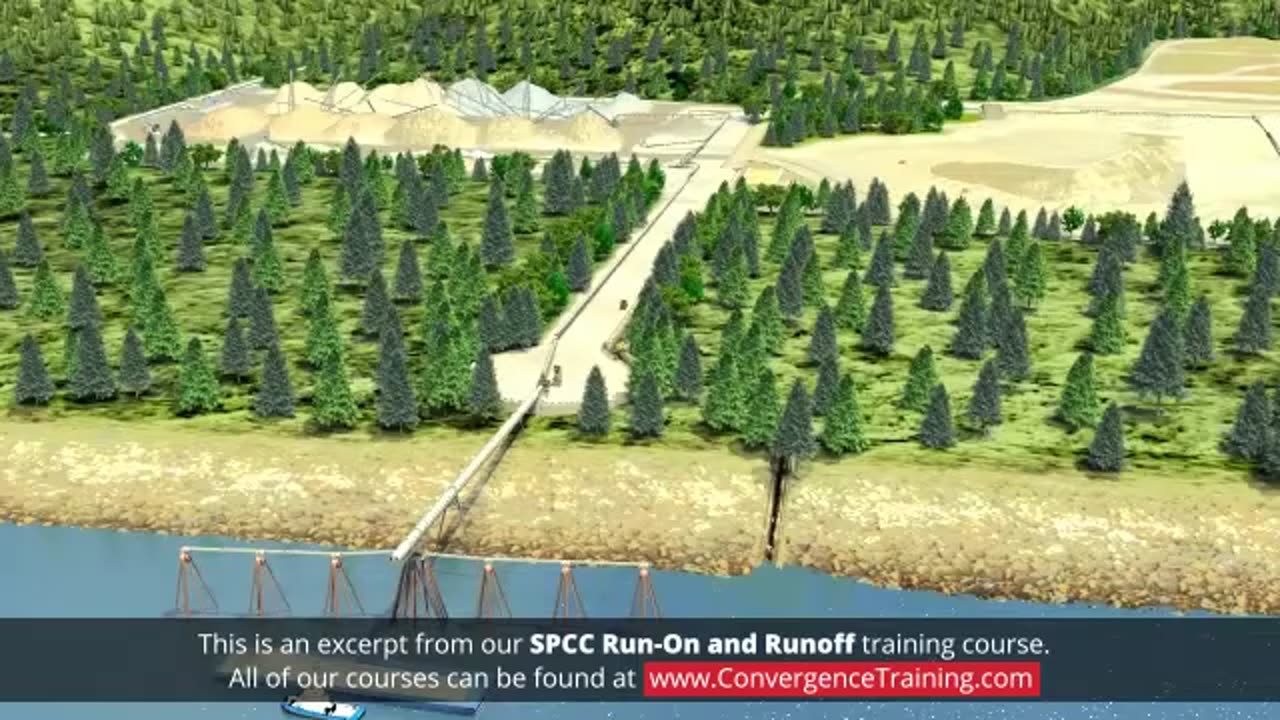

SPCC Run On and Runoff Training

### **SPCC Run-On and Runoff Training**

This training focuses on the requirements and best practices for managing *run-on* and *runoff* in facilities regulated under the Spill Prevention, Control, and Countermeasure (SPCC) rule. It ensures participants understand how to prevent oil discharges into navigable waters or adjoining shorelines by properly addressing stormwater, drainage systems, and secondary containment structures.

---

### **Training Objectives**

1. Understand the SPCC rule's requirements related to run-on and runoff.

2. Identify potential sources of oil contamination in stormwater.

3. Learn best practices for managing run-on and runoff to prevent spills and pollution.

4. Develop and implement effective secondary containment and diversion systems.

5. Conduct inspections and maintain compliance with SPCC standards.

---

### **Key Training Modules**

#### **1. Overview of the SPCC Rule**

- **What is SPCC?**

- EPA regulation (40 CFR Part 112) aimed at preventing oil discharges into waterways.

- **Applicability**

- Facilities with aggregate aboveground oil storage exceeding 1,320 gallons or 42,000 gallons in buried tanks.

- **Run-On and Runoff in SPCC Plans**

- How run-on (external water entering the site) and runoff (site water leaving) relate to spill prevention.

---

#### **2. Understanding Run-On and Runoff Risks**

- **Potential Hazards**

- Run-on can carry water into storage or containment areas, displacing oil.

- Runoff can spread oil spills to navigable waters or storm drains.

- **Sources of Oil-Contaminated Runoff**

- Leaking equipment or tanks.

- Overflows or spills during transfers.

- Rainfall mixing with oily residues on surfaces.

---

#### **3. Best Practices for Run-On and Runoff Control**

- **Secondary Containment Design**

- Ensure containment structures are sized to hold 110% of the largest tank and additional precipitation.

- Install berms, dikes, or trenches to redirect run-on water away from oil storage areas.

- **Stormwater Management Systems**

- Use oil-water separators or filtration systems to treat contaminated runoff.

- Divert clean stormwater away from oily areas using slope grading, curbs, or drainage systems.

- **Inspection and Maintenance**

- Regularly inspect secondary containment for cracks or damage.

- Ensure drain valves are securely closed except during authorized draining.

- **Spill Response Planning**

- Maintain spill kits and ensure workers are trained on how to deploy them quickly.

- Establish emergency protocols for stormwater management during spills.

---

#### **4. Monitoring and Testing**

- **Water Quality Monitoring**

- Test runoff water for oil or hazardous materials before discharge.

- Understand regulatory discharge limits (e.g., NPDES permit requirements).

- **Leak Detection Systems**

- Use sensors or alarms in containment areas to detect breaches or overflows early.

---

#### **5. SPCC Compliance Documentation**

- **Updating SPCC Plans**

- Include site-specific details on run-on and runoff management.

- Document inspection schedules, maintenance records, and spill response drills.

- **Inspection Checklists**

- Use standardized forms to assess berm integrity, drainage systems, and spill containment areas.

---

### **Interactive Exercises**

1. **Site Walkthrough and Hazard Identification**

- Participants identify run-on and runoff risks in a mock facility or using real facility plans.

2. **Containment Design Workshop**

- Hands-on exercise to calculate secondary containment capacity and design flow diversion systems.

3. **Emergency Drill**

- Practice spill response and stormwater containment during a simulated heavy rainfall event.

---

### **Training Deliverables**

- **Workbook:** Covers SPCC rule requirements, best practices, and sample inspection forms.

- **Sample SPCC Plan Addendum:** Specific to run-on and runoff management.

- **Certificate of Completion:** Verifies participants have completed the training.

---

Would you like me to help create a detailed SPCC training agenda or checklist specific to your facility?

-

7:58

7:58

HSESafetyInformation

9 months agoAuthentic Peshawari Rosh _ Namkeen Gosht Recipe __ Traditional KPK and Baluchistan

801 -

1:56:01

1:56:01

Inverted World Live

3 hours agoHome is Where The Great Pacific Garbage Patch is | Ep. 148

35.5K6 -

LIVE

LIVE

Drew Hernandez

22 hours agoTHE CURRENT STATE OF MAGA 2025 W/ GUEST: OWEN SHROYER

934 watching -

34:21

34:21

Stephen Gardner

4 hours agoThey have NO IDEA what they just UNLEASHED!!

12.1K46 -

3:08:15

3:08:15

Decoy

4 hours agoFinally

34.2K10 -

2:55:01

2:55:01

TimcastIRL

4 hours agoTrump Calls Democrat RETARDED, Whistleblower EXPOSES Democrat FRAUD | Timcast IRL

177K51 -

LIVE

LIVE

Akademiks

3 hours agoMeg Thee Stallion spent $2 mil on lawyers to win $59k vs Milagro! 50 Cent BURIES Diddy. SNAKES HIM!

1,039 watching -

LIVE

LIVE

SpartakusLIVE

4 hours agoI'M BACK from Florida || The RETURN to the Spartan Stronghold

456 watching -

1:38:45

1:38:45

Joker Effect

3 hours agoWhy is everything so DIFFICULT?! Cuffem, Gypsy Crusader, WVAGABOND is getting SUED?! IDuncle is mad!

16.1K1 -

54:46

54:46

Flyover Conservatives

22 hours agoInside the Kill Zones: Kidnappings, Camps & the War on Nigerian Christians Exposed - Judd Saul | FOC Show

20.6K1