Premium Only Content

Steel Erection Safety Training

**Steel Erection Safety Training** is crucial for workers involved in constructing steel-framed structures, as the work involves significant hazards such as falls, collapsing structures, and heavy equipment. Proper training ensures compliance with OSHA standards (29 CFR 1926 Subpart R) and reduces risks of injury or fatalities. Below is an outline for effective **Steel Erection Safety Training**:

---

## **1. Overview of Steel Erection Hazards**

- **Common Risks in Steel Erection:**

- Falls from heights.

- Collapsing steel structures.

- Falling tools and materials.

- Equipment-related accidents (e.g., cranes, hoists).

- Exposure to sharp edges and weld points.

- **Statistics and Incident Examples:**

- Highlight real-life cases to emphasize the importance of safety.

---

## **2. OSHA Standards for Steel Erection**

- Overview of **29 CFR 1926 Subpart R** requirements.

- Key focus areas:

- Fall protection.

- Stability and structural integrity.

- Safe hoisting and rigging.

- Use of safety equipment.

---

## **3. Pre-Erection Planning**

- **Site-Specific Safety Plans:**

- Identify potential hazards on-site.

- Develop written plans for safety and structural stability.

- **Safety Meetings and Communication:**

- Daily briefings on specific tasks and hazards.

- Use of clear hand signals for crane operators and riggers.

- **Inspection of Equipment and Materials:**

- Ensure all tools, cranes, and hoists are inspected and in good condition.

---

## **4. Fall Protection**

- **OSHA Fall Protection Requirements:**

- Mandatory use of fall arrest systems for work over **15 feet**.

- Connecting points for lanyards or lifelines must support 5,000 lbs.

- **Fall Arrest Equipment:**

- Harnesses, lanyards, lifelines, and anchor points.

- Inspecting and maintaining fall protection equipment.

- **Controlled Decking Zones (CDZ):**

- Designated areas where workers can operate without full fall protection under certain conditions.

---

## **5. Stability and Structural Integrity**

- **Erection Sequence:**

- Follow engineered plans for proper sequence to maintain stability.

- **Anchor Bolts and Connections:**

- Ensure bolts and welds meet specifications before proceeding.

- **Structural Inspections:**

- Conduct inspections at each stage to confirm stability.

---

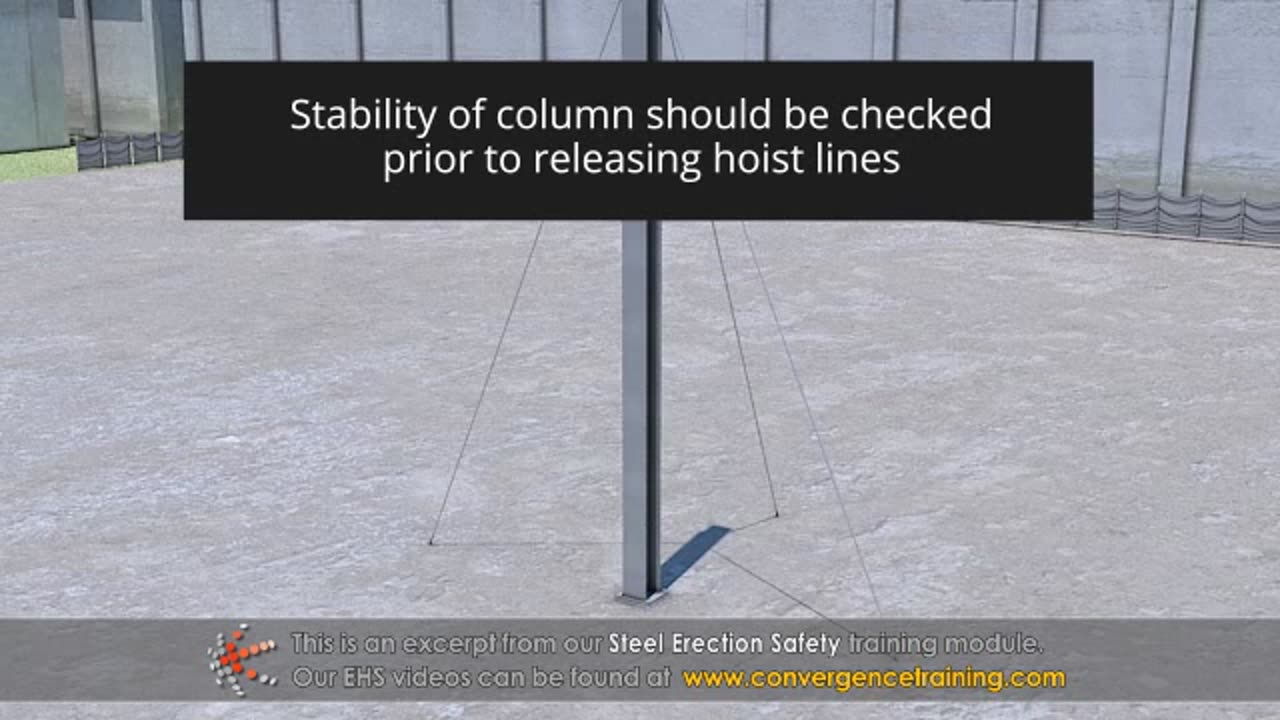

## **6. Crane and Hoisting Safety**

- **Crane Operation Rules:**

- Only qualified operators should handle cranes.

- Adhere to load capacity limits.

- **Rigging Safety:**

- Use proper slings, shackles, and hooks.

- Inspect rigging equipment before use.

- **Hand Signal Training:**

- Train workers on standard crane hand signals for clear communication.

---

## **7. Material Handling**

- **Avoiding Falling Objects:**

- Use tool lanyards and secure materials during lifting.

- **Proper Storage:**

- Store steel beams and materials safely to prevent tipping or rolling.

- **Hoisting Guidelines:**

- Ensure workers are not standing under lifted loads.

---

## **8. Personal Protective Equipment (PPE)**

- Mandatory PPE for steel erection:

- Hard hats.

- Steel-toed boots.

- Cut-resistant gloves.

- Safety glasses.

- Hearing protection, if required.

---

## **9. Emergency Response Preparedness**

- **Evacuation Procedures:**

- Train workers on escape routes and emergency plans.

- **First Aid Training:**

- Ensure workers are trained in basic first aid and CPR.

- **Rescue Equipment:**

- Have rescue harnesses, ladders, and lifting equipment on site.

---

## **10. Hands-On Training and Drills**

- **Practical Exercises:**

- Simulated steel erection tasks with safety protocols.

- Demonstrating proper use of fall protection systems.

- **Emergency Scenarios:**

- Conduct rescue drills for workers in fall-arrest situations.

---

## **11. Review and Compliance**

- Regular refresher training.

- Periodic safety audits to ensure compliance with OSHA standards.

- Open discussions for workers to raise concerns or suggest improvements.

---

### **Key Takeaways:**

- **Plan ahead** to identify and mitigate risks.

- **Use fall protection** and inspect equipment regularly.

- **Communicate clearly** during crane and hoisting operations.

- Maintain a culture of safety awareness on site.

Would you like to focus on creating a detailed checklist or develop materials for specific safety drills?

-

6:54

6:54

HSESafetyInformation

6 months ago6 Must Try Breakfast recipes By Food Fusion

351 -

LIVE

LIVE

Akademiks

4 hours agoYNW Melly MIGHT BE COOKED! Co-D TELLLING? 6ix9ine vs Young Thug . Drake vs Kaicenat? HOLLY

1,154 watching -

4:46:45

4:46:45

Drew Hernandez

11 hours agoHORRIFYING: FULL FOOTAGE OF IRYNA ZARUTSKA MURDER HAS BEEN RELEASED

30.9K25 -

2:42:09

2:42:09

TimcastIRL

7 hours agoNATO Scramble Air Force Over Russian Incursion Into Poland, HIGH ALERT Reported | Timcast IRL

178K99 -

25:46

25:46

Man in America

10 hours agoALERT: Gold Prices FLASH OMINOUS WARNING for the Dollar—Are You READY??

34.8K17 -

58:27

58:27

Sarah Westall

6 hours agoWar Exploding Around the World: Nepal, Israel, Qatar, Venezuela, Thailand, more... w/ Michael Yon

41K13 -

LIVE

LIVE

SpartakusLIVE

8 hours agoThe Most INSANE Snipes EVER || Solo to Duos w/ StevieT - PUBG or Mordor Later?!

406 watching -

1:11:40

1:11:40

Flyover Conservatives

17 hours agoThe Truth About Israel & End Times Nobody Wants to Say - Phil Hotsenpiller | FOC Show

37.9K11 -

LIVE

LIVE

GritsGG

5 hours agoSweaty Ranked Grind! Most Wins in WORLD! 3600+!

208 watching -

![[ Tekken Tuesday ] TNS Tekken Tournament Watch Party](https://1a-1791.com/video/fww1/5b/s8/1/4/a/C/g/4aCgz.0kob-small--Tekken-Tuesday-TNS-Watch-P.jpg) 4:04:31

4:04:31

CHiLi XDD

5 hours ago[ Tekken Tuesday ] TNS Tekken Tournament Watch Party

22.8K4