Premium Only Content

Hydrogen Sulfide Awareness Training

Hydrogen Sulfide (H₂S) Awareness Training is essential for workers who may encounter hydrogen sulfide gas in their work environments, such as in oil and gas, wastewater treatment, or agricultural industries. This training aims to inform employees about the dangers of H₂S, how to recognize it, and how to respond safely.

---

### **Hydrogen Sulfide Awareness Training Outline**

#### **1. Introduction to Hydrogen Sulfide**

- **What is H₂S?**

- A colorless gas with a characteristic "rotten egg" odor at low concentrations.

- Naturally occurring in crude oil, natural gas, sewers, and decaying organic matter.

- Importance of H₂S awareness in the workplace.

- Regulatory requirements (e.g., OSHA standard **29 CFR 1910.1000** and ANSI Z390.1).

---

#### **2. Properties and Characteristics of H₂S**

- Chemical properties:

- Formula: H₂S.

- Heavier than air; accumulates in low-lying areas.

- Flammable and explosive at certain concentrations.

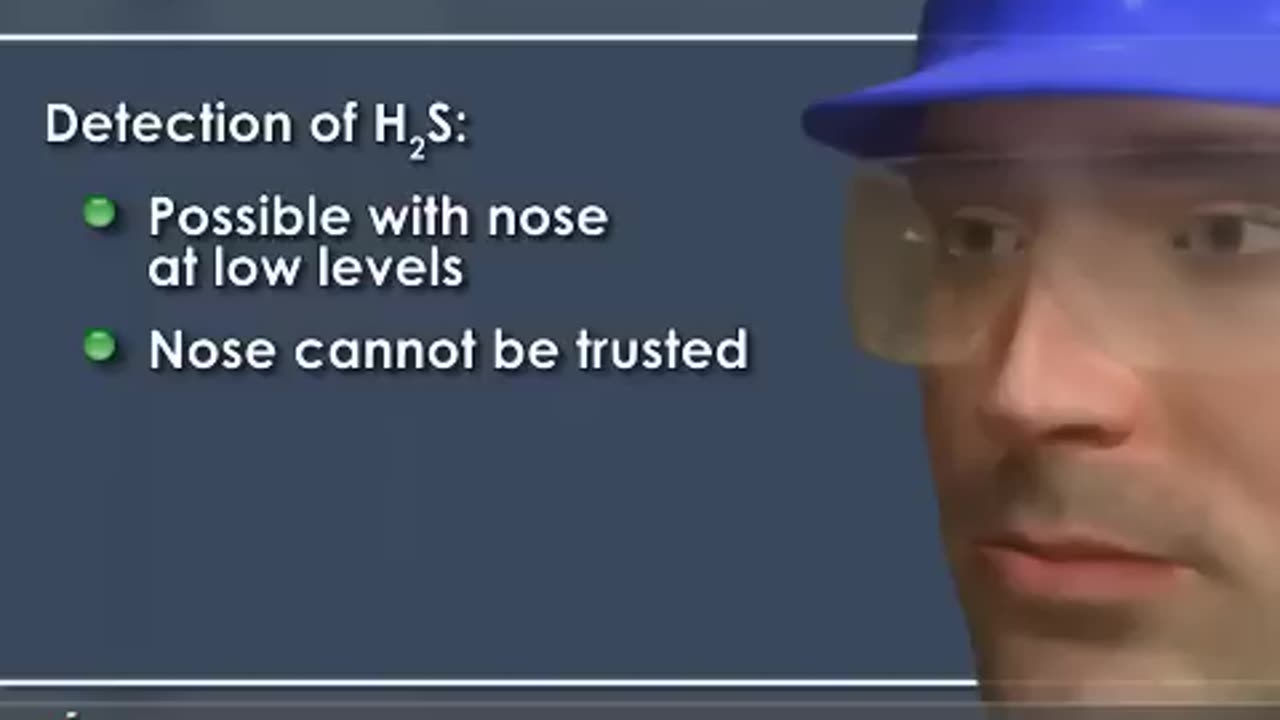

- Detection challenges:

- Odor threshold is unreliable due to olfactory fatigue (loss of smell at higher levels).

---

#### **3. Health Effects of H₂S Exposure**

- Low concentrations:

- Eye and throat irritation.

- Headaches and dizziness.

- Moderate concentrations:

- Nausea, coughing, difficulty breathing.

- High concentrations:

- Unconsciousness or death due to respiratory paralysis.

- OSHA Permissible Exposure Limit (PEL): 20 ppm (ceiling limit).

---

#### **4. Recognizing H₂S Exposure**

- **Concentration and effects:**

- 0.01-1 ppm: Odor threshold (rotten egg smell).

- 10-50 ppm: Eye irritation, dizziness.

- 100 ppm: Immediate danger to life and health (IDLH).

- >300 ppm: Rapid unconsciousness and potential fatality.

- Symptoms of exposure and when to take action.

---

#### **5. Monitoring and Detection Methods**

- Personal H₂S monitors:

- How to wear and interpret alarms.

- Fixed gas detection systems:

- Placement and maintenance.

- Air monitoring protocols for high-risk areas.

---

#### **6. Preventive Measures**

- **Engineering controls:**

- Ventilation and air circulation in confined spaces.

- **Work practice controls:**

- Pre-job risk assessments.

- Avoid working alone in H₂S risk areas.

- **Personal protective equipment (PPE):**

- Respirators (air-purifying or self-contained breathing apparatus).

- Proper use and maintenance of PPE.

---

#### **7. Emergency Response Procedures**

- What to do if H₂S is detected:

- Evacuate the area immediately.

- Use the "buddy system" for safety.

- Rescue procedures:

- Only trained personnel with proper equipment should perform rescues.

- First aid for exposure:

- Move victim to fresh air.

- Administer CPR if trained and necessary.

- Seek medical attention immediately.

---

#### **8. Confined Space Entry**

- Risks of H₂S in confined spaces (e.g., tanks, pits, sewers).

- OSHA confined space entry requirements:

- Permit system.

- Testing for H₂S and other hazardous gases before entry.

- Continuous monitoring during work.

---

#### **9. Employer and Employee Responsibilities**

- **Employer duties:**

- Provide H₂S training, detection equipment, and PPE.

- Implement hazard communication programs.

- **Employee duties:**

- Follow all safety procedures and use equipment as instructed.

- Report unsafe conditions immediately.

---

#### **10. Practical Exercises and Scenarios**

- Hands-on demonstration:

- Using personal H₂S detectors and PPE.

- Simulating H₂S alarm response.

- Emergency drills:

- Practicing evacuation and rescue procedures.

---

#### **11. Quiz and Certification**

- Administer a knowledge assessment.

- Provide certificates to employees who complete the training successfully.

---

Would you like to customize this training for your workplace, or need help with creating materials or a presentation?

-

7:58

7:58

HSESafetyInformation

4 months agoAuthentic Peshawari Rosh _ Namkeen Gosht Recipe __ Traditional KPK and Baluchistan

611 -

LIVE

LIVE

Etheraeon

5 hours agoWorld of Warcraft: The War Within | Timewalking + Battlegrounds | New Emojis Added!

69 watching -

3:34:35

3:34:35

Barry Cunningham

7 hours agoPRESIDENT TRUMP HAS HAD AN AMAZINGLY SUCCESSFUL WEEK! AND MORE NEWS!

88.9K53 -

LIVE

LIVE

Damysus Gaming

1 hour agoDune: Awakening - The Grind Continues - Pushing to Complete More Story!!!

48 watching -

9:03

9:03

MattMorseTV

8 hours ago $0.71 earnedTrump just SHATTERED the RECORD.

5.69K12 -

LIVE

LIVE

BrancoFXDC

55 minutes agoPlaying Warzone - Resurgence

55 watching -

LIVE

LIVE

Lindyrigg87

1 hour agoSaturday Night Gaming

41 watching -

LIVE

LIVE

SavageJayGatsby

2 hours agoSpicy Saturday! w/ Mally Mouse - Wedding in 4 Months!!!

1,499 watching -

LIVE

LIVE

Cripiechuccles

2 hours ago😁💚💙SHATTERDAY WITH CRIPIE💚💙RUMLUV ACTIVATE👌COME IN AND SAY HI!!:😁

61 watching -

LIVE

LIVE

Eternal_Spartan

3 hours agoClair Obscur: Expedition 33 Pt. 5 (Story Finale) | USMC Vet | Come Join the Best Chat on Rumble!!!!

129 watching