Premium Only Content

Chain Drive Basics

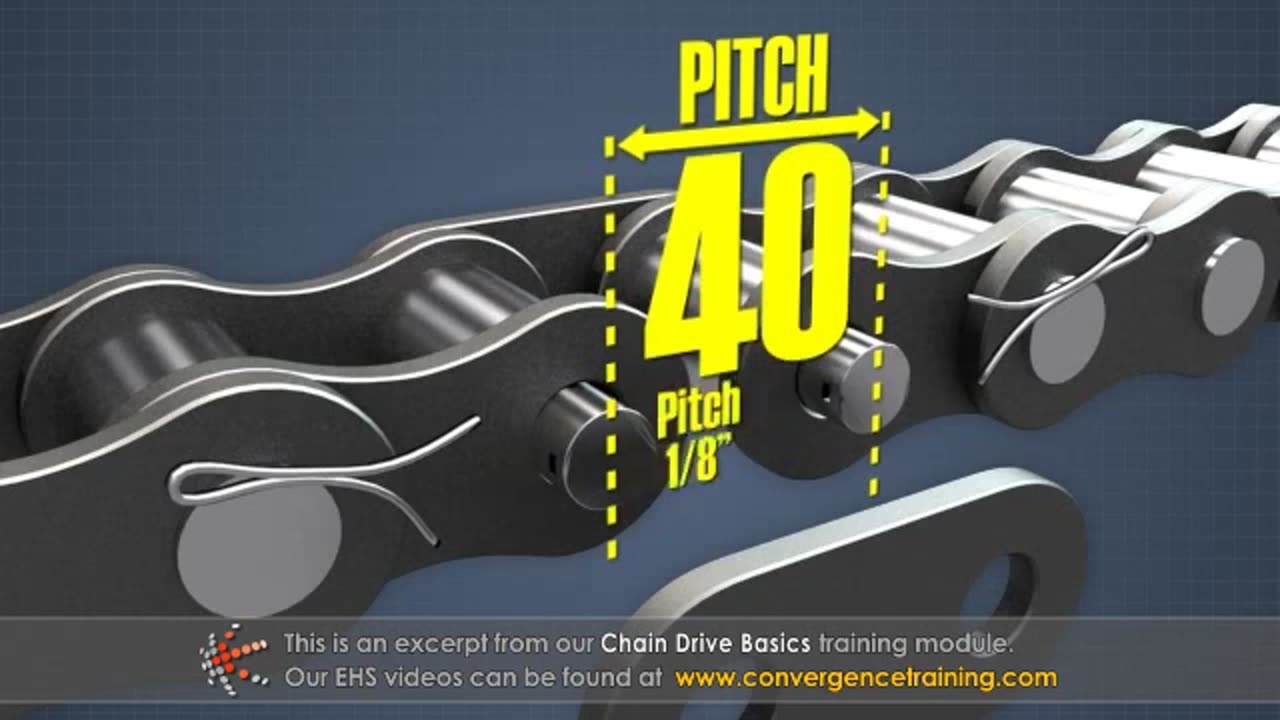

A **chain drive** is a mechanical system used to transmit power between two or more shafts by means of a continuous chain running over sprockets. It is commonly used in bicycles, motorcycles, conveyors, and industrial machinery for power transmission.

---

### **Key Components of a Chain Drive**

1. **Chain**:

- Made of interlinked metal links, providing flexibility and strength.

- Types include roller chains (most common), silent chains, and leaf chains.

2. **Sprockets**:

- Toothed wheels that mesh with the chain.

- Can vary in size to adjust the speed or torque of the driven shaft.

3. **Driver and Driven Shafts**:

- **Driver Shaft**: The input shaft connected to the power source (e.g., motor or engine).

- **Driven Shaft**: The output shaft that receives power from the chain drive.

---

### **How a Chain Drive Works**

1. Power is applied to the **driver sprocket**, causing it to rotate.

2. The sprocket teeth engage the chain links, pulling the chain along.

3. The chain transmits power to the **driven sprocket**, causing it to rotate.

4. This rotation powers the attached machinery or equipment.

---

### **Types of Chain Drives**

1. **Simple Chain Drive**:

- A single chain connects two sprockets (driver and driven).

- Used for straightforward power transmission.

2. **Compound Chain Drive**:

- Multiple sprockets and chains are used for transmitting power to multiple shafts.

- Common in industrial machinery.

3. **Reverted Chain Drive**:

- Used when the driver and driven shafts are on the same axis.

- Includes an intermediate sprocket to transmit power.

4. **Silent Chain Drive**:

- Uses chains with toothed links for quieter operation.

- Suitable for high-speed and precision applications.

---

### **Advantages of Chain Drives**

1. **Durability**: Can handle heavy loads and operate under adverse conditions (dust, moisture, etc.).

2. **Efficiency**: High mechanical efficiency (typically 95-98%).

3. **No Slippage**: Positive engagement between the chain and sprockets prevents slippage.

4. **Adjustability**: Easy to change speed or torque by varying sprocket sizes.

5. **Compact**: Requires less space than belt drives for the same power transmission.

---

### **Disadvantages of Chain Drives**

1. **Maintenance**: Requires regular lubrication and tensioning to prevent wear.

2. **Noise**: Can be noisier than belt drives, especially at high speeds.

3. **Cost**: Higher initial cost compared to belt drives.

4. **Wear and Tear**: Chains and sprockets may wear over time, requiring replacement.

---

### **Applications of Chain Drives**

1. **Bicycles and Motorcycles**: For speed and power transmission.

2. **Conveyors**: In manufacturing and packaging industries.

3. **Agriculture**: Used in tractors, harvesters, and other equipment.

4. **Industrial Machinery**: For heavy-duty applications like cranes and elevators.

---

### **Maintenance Tips**

1. **Lubrication**: Apply proper lubricant to reduce friction and prevent corrosion.

2. **Tension Adjustment**: Keep the chain taut to avoid excessive wear or slippage.

3. **Alignment**: Ensure the sprockets are aligned to prevent uneven wear.

4. **Inspection**: Regularly check for worn-out links or teeth and replace them promptly.

---

Let me know if you’d like more details, such as specific chain types, design calculations, or troubleshooting tips! 😊

-

2:32:43

2:32:43

FreshandFit

12 hours agoAndrew Wilson VS Gary The Numbers Guy Astrology & Numerology Debate!

83.7K46 -

Dr Disrespect

10 hours ago🔴LIVE - DR DISRESPECT - TRIPLE THREAT CHALLENGE - RIVALS, PUBG, WARZONE

197K35 -

1:15:03

1:15:03

Dad Dojo Podcast

8 hours ago $0.93 earnedEP16: Parenting: Then vs Now

23K -

53:58

53:58

Sarah Westall

3 hours agoBlack Pilled vs Learning Reality and Maintaining Perspective, AI Reality w/ Johnny Vedmore

38.5K -

55:01

55:01

LFA TV

1 day agoJan. 6, 2021, vs. Jan. 6, 2025 | TRUMPET DAILY 1.6.25 7pm

28.1K1 -

1:19:27

1:19:27

The Big Mig™

1 day agoLimitless Health with Calley Means

35.5K7 -

1:37:26

1:37:26

Redacted News

7 hours agoBREAKING! Trump Effect is Real Justin Trudeau Resigns in Disgrace

154K215 -

49:08

49:08

Kimberly Guilfoyle

7 hours agoEnding Injustice and the 100 Day Agenda, Live with Joseph McBride and Mark Lucas | Ep. 186

47.5K6 -

56:29

56:29

Candace Show Podcast

6 hours agoYes, Internet. I Am Pregnant...AGAIN. | Candace Ep 126

116K246 -

1:08:16

1:08:16

The Amber May Show

10 hours ago $0.74 earnedU.K. Political Prisoner Tommy Robinson | Cyber Truck Explosion | Soros & Clinton Medal Of Freedom

20.3K1