Premium Only Content

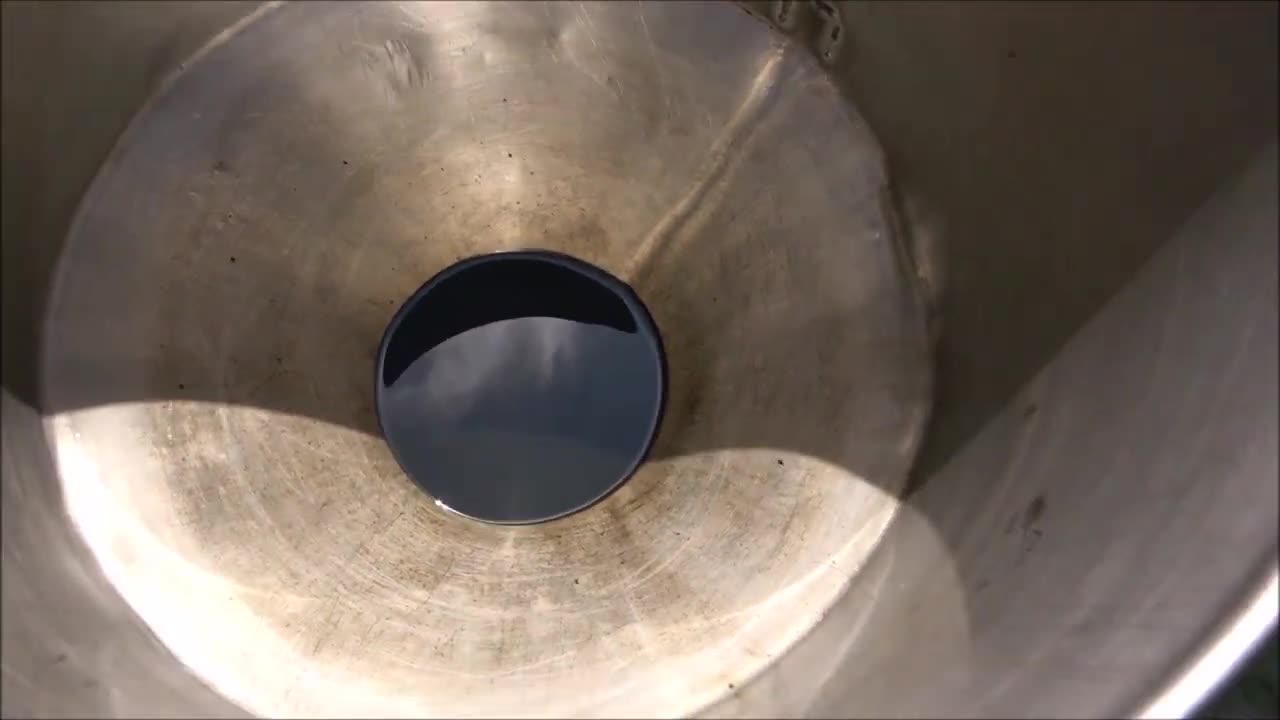

Oil Reformer vs Oil Distiller.

Reforming typically operates at elevated temperatures, similar to destructive distillation, but in a continuous process. This process transforms a uniform, mostly heavy hydrocarbon feedstock into a variety of different hydrocarbon fuels, ranging from diesel fractions to petroleum gas. In semi-continuous reformers, also known as coking distillers, the feedstock is further broken down into solid carbon, which needs to be removed from the reactor cylinder before any subsequent distillation.

Continuous oil distillation generally occurs at temperatures no higher than the actual boiling point of the oil. As a result, only oil is produced, while impurities, additives, and bitumen—substances with higher boiling points—are separated from the oil. In this process, no destructive distillation takes place. The base oil can then be chemically cleaned and used either as a base for lubricants or as diesel fuel.

Therefore, if the goal is to produce a variety of products, reforming is the preferred method. The oil distiller can be effectively used for a secondary distillation of reforming outputs, such as petrol engine oil, automatic transmission fluids, or tire pyrolysis oil.

Website: https://www.ferromit.com/index.html

Contact: https://www.ferromit.com/contact.html

Construction plans: https://www.doubloonbay.net

#wmo #reformer #refinery #blackdiesel #automobile #fuel #pyrolysis

-

2:08:25

2:08:25

Side Scrollers Podcast

21 hours agoEXCLUSIVE: Marty O’Donnell BREAKS SILENCE On Bungie Drama + Kotaku Hypocrisy + MORE | Side Scrollers

31.7K5 -

Wahzdee

3 hours agoBack on BF2042 – Which Sniper Is Actually Worth It?

9231 -

2:31:49

2:31:49

MattMorseTV

21 hours ago $0.72 earned🔴Trump's Oval Office BOMBSHELL.🔴

39.7K55 -

25:14

25:14

GritsGG

17 hours agoRank 1 Player Spectates Casual Solos!

23.8K -

LIVE

LIVE

Lofi Girl

2 years agoSynthwave Radio 🌌 - beats to chill/game to

546 watching -

4:33:40

4:33:40

FreshandFit

11 hours agoAfter Hours w/ Girls

261K139 -

2:33:36

2:33:36

Badlands Media

12 hours agoOnlyLands Ep. 21: From Trump’s VP Pick to Green Energy Grift

83.1K21 -

1:07:26

1:07:26

Inverted World Live

15 hours agoThe War Against Robots w/ Joe Allen

115K5 -

6:08:31

6:08:31

SpartakusLIVE

15 hours agoWARZONE NUKE IS BACK?! || Solo Challenge CHAMPION to start, duos w/ the Dawg later

114K1 -

1:00:18

1:00:18

Man in America

16 hours agoBig Pharma’s Empire of Lies Is COLLAPSING as People Turn to Natural Medicine

71.9K34