Premium Only Content

Clean in place System | CIP | 3D Animation Tank Cleaning Equipment | #ssec #cleaninplace #cip

Please click the below links for more details: 👇

Product Link: https://www.ssengrindia.com/ln/dpm/CI...

Contact us: https://b24-jupuge1.bitrix24.site/crm...

Clean in place System | CIP | 3D Animation Tank Cleaning Equipment | #ssec #cleaninplace #cip

In the modern landscape of manufacturing and production, maintaining stringent hygiene standards is paramount. Whether it's in the food and beverage industry, pharmaceuticals, cosmetics, or any sector that deals with sensitive materials or products, the cleanliness of equipment and machinery cannot be compromised. Clean-in-Place (CIP) systems have emerged as a revolutionary solution to ensure efficient and thorough cleaning of equipment without the need for disassembly, saving time, labor, and reducing the risk of contamination.

Understanding Clean-in-Place (CIP) Systems:

Clean-in-Place (CIP) refers to a method of cleaning the interior surfaces of equipment, pipes, and other machinery without the need for manual disassembly. This is achieved by circulating cleaning solutions, detergents, and sanitizing agents through the equipment, effectively removing residue, contaminants, and other unwanted materials. The primary goal of a CIP system is to maintain consistent hygiene and minimize downtime between production runs.

Components of a CIP System:

A typical Clean-in-Place system consists of several key components that work together to ensure effective cleaning:

1. CIP Tanks: These tanks hold cleaning solutions and can be equipped with heaters, agitators, and recirculation systems to ensure proper mixing and temperature control.

2. Pumps: Pumps are used to move the cleaning solutions through the equipment being cleaned. They maintain the required flow rates and pressures for effective cleaning.

3. Spray Devices: Nozzles, jets, and spray balls are used to distribute the cleaning solution inside the equipment evenly, ensuring all surfaces are thoroughly cleaned.

4. Control Systems: Modern CIP systems are automated and controlled using advanced software. This allows for precise control of cleaning parameters such as temperature, flow rate, and duration.

Advantages of Clean-in-Place Systems:

1. Efficiency: CIP systems reduce the need for manual cleaning, significantly reducing downtime between production cycles. This boosts overall operational efficiency and productivity.

2. Consistency: Automated CIP systems ensure that cleaning processes are consistent and adhere to predetermined parameters, eliminating the risk of human error.

3. Cost Savings: While the initial investment in a CIP system might be substantial, the long-term cost savings from reduced labor, less water and chemical usage, and decreased downtime can be substantial.

4. Reduced Contamination Risk: CIP systems minimize the chances of cross-contamination, ensuring that equipment is thoroughly cleaned before the next production cycle begins.

Challenges and Considerations:

While Clean-in-Place systems offer numerous advantages, there are a few challenges and considerations to keep in mind:

1. System Design: Proper design and engineering of a CIP system are critical to ensure effective cleaning and prevent dead zones where cleaning solutions might not reach.

2. Validation: Ensuring that the CIP system is working as intended requires regular testing and validation to confirm its efficacy.

3. Compatibility: Different products and materials might require different cleaning agents and procedures, necessitating flexibility in the CIP system's design.

4. Training: Operators must be well-trained to operate and maintain CIP systems effectively. A lack of understanding can lead to improper cleaning or system malfunctions.

Importance of using Chemicals in CIP Cycles Design Considerations for CIP Systems When designing a CIP system, there are several design elements to keep in mind to ensure the constructed system fully performs its intended function.

YouTube: https://www.youtube.com/ssengineersconsultants

LinkedIn: https://www.linkedin.com/company/ss-engineers-&-consultants

Twitter: https://www.twitter.com/ssengrindia

Facebook: https://www.facebook.com/ssengineersandconsultantspvtltd

Website: https://www.ssengrindia.com

-

LIVE

LIVE

Steven Crowder

2 hours ago🔴BREAKING: Tulsi Drops Major Receipts Proving Obama Treason over Trump Russia Hoax

78,874 watching -

LIVE

LIVE

Nikko Ortiz

18 minutes agoLive - Most Painful Clips

235 watching -

UPCOMING

UPCOMING

The Mel K Show

23 minutes agoMORNINGS WITH MEL K - Seditious Conspiracy to Defraud the PEOPLE of the United States of America 7-23-25

-

45:25

45:25

The Rubin Report

1 hour ago'Shark Tank' Legend Destroys Economy Narrative w/ One Fact

11.7K4 -

LIVE

LIVE

Law&Crime

3 hours ago $1.39 earnedLIVE: Bryan Kohberger Sentencing — ID v. Bryan Kohberger

910 watching -

LIVE

LIVE

LFA TV

14 hours agoLFA TV ALL DAY STREAM - WEDNESDAY 7/23/25

5,595 watching -

UPCOMING

UPCOMING

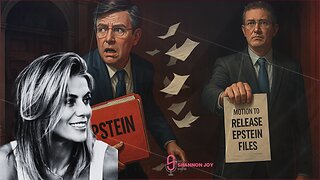

The Shannon Joy Show

1 hour ago🔥🔥Running Scared!! Speaker Mike Johnson SHUTS DOWN The House To Avoid The Massie Vote To Release The Epstein Files!🔥🔥

243 -

UPCOMING

UPCOMING

Grant Stinchfield

17 minutes agoIt's NOT Mortgage Fraud... It's Election Fraud! Strip Sen. Schiff of His Seat Now!

-

1:01:05

1:01:05

VINCE

3 hours agoOBAMA: Is It Treason Then? | Episode 91 - 07/23/25

178K83 -

1:14:59

1:14:59

The Officer Tatum

1 hour agoBREAKING: Tulsi Gabbard RELEASES NEW EVIDENCE On Obama, + MORE | EP 145

20.5K6