Premium Only Content

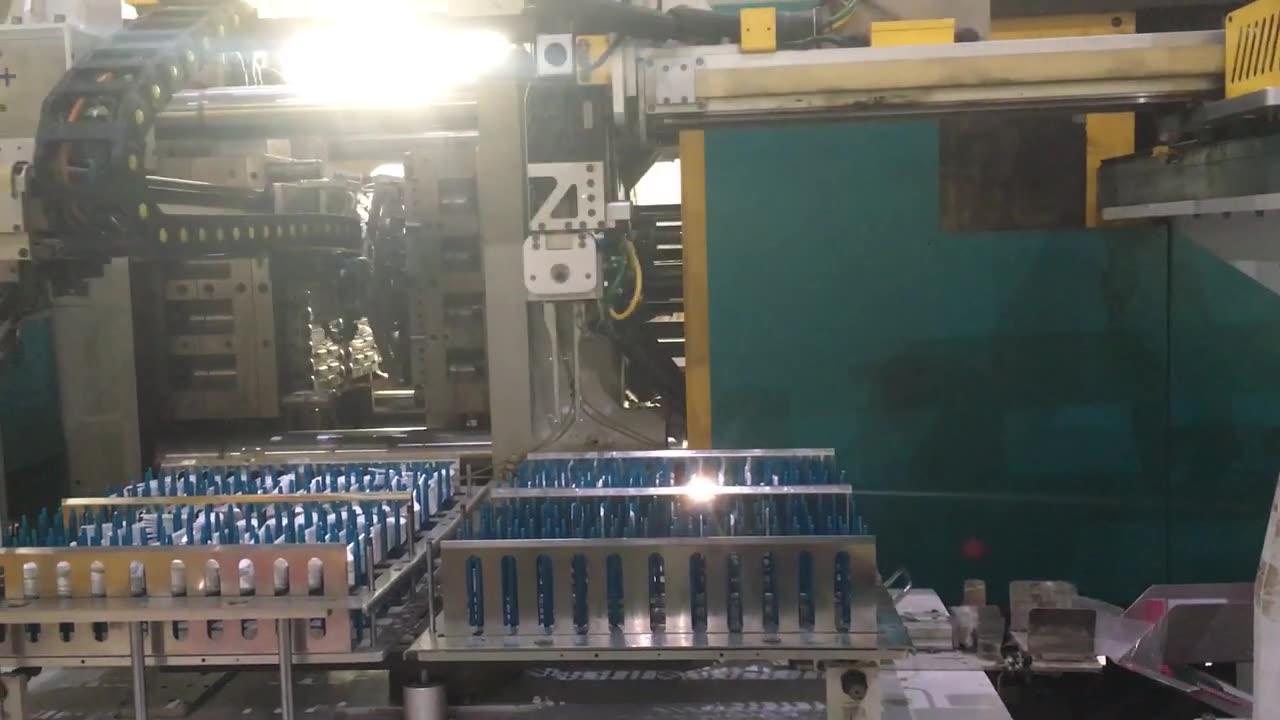

Plastic cutlery Injection Machine

Plastic cutlery Injection Machine

Plastic cutlery injection molding machines are used in the manufacturing process of producing plastic utensils such as forks, knives, and spoons. These machines operate through the injection molding process, which involves melting plastic pellets and injecting the molten material into a mold cavity to form the desired shape. Here is an overview of the key components and steps involved in the plastic cutlery injection molding process:

Key Components of a Plastic Cutlery Injection Molding Machine:

Injection Unit:

This unit is responsible for melting and injecting the plastic material into the mold.

It includes a hopper for holding plastic pellets, a barrel for heating and melting the plastic, and a screw or plunger for injecting the molten plastic into the mold.

Mold:

The mold is a crucial part of the process, as it defines the shape and features of the plastic cutlery.

It consists of two halves (cavities) that come together to form the final product.

Clamping Unit:

The clamping unit holds the mold in place during injection and cooling.

It includes a clamping mechanism to securely close and hold the mold halves together.

Cooling System:

After injection, the plastic inside the mold needs to cool and solidify.

A cooling system helps regulate the temperature and speed up the solidification process.

Ejector System:

Once the plastic has solidified, the ejector system pushes the finished plastic cutlery out of the mold.

Control System:

The control system manages and regulates the entire injection molding process, including temperature control, injection speed, and other parameters.

Plastic Cutlery Injection Molding Process:

Material Loading:

Plastic pellets are loaded into the hopper of the injection molding machine.

Injection:

The plastic pellets are melted in the barrel and injected into the mold cavity.

Cooling:

The molten plastic inside the mold cools and solidifies to take the shape of the cutlery.

Ejection:

The ejector system pushes the finished plastic cutlery out of the mold.

Quality Control:

The produced plastic cutlery undergoes inspection for defects, ensuring quality standards are met.

Packaging:

The final step involves packaging the plastic cutlery for distribution.

When seeking a plastic cutlery injection molding machine, it's essential to consider factors such as the machine's capacity, precision, energy efficiency, and the type of plastic materials it can process. Manufacturers and suppliers of plastic molding machines can provide specific details about their equipment, and you may also explore industry exhibitions and trade shows to learn more about available technologies.

-

25:14

25:14

GritsGG

12 hours agoRank 1 Player Spectates Casual Solos!

2.39K -

LIVE

LIVE

Lofi Girl

2 years agoSynthwave Radio 🌌 - beats to chill/game to

1,736 watching -

4:33:40

4:33:40

FreshandFit

7 hours agoAfter Hours w/ Girls

219K89 -

2:33:36

2:33:36

Badlands Media

8 hours agoOnlyLands Ep. 21: From Trump’s VP Pick to Green Energy Grift

57.7K6 -

1:07:26

1:07:26

Inverted World Live

11 hours agoThe War Against Robots w/ Joe Allen

90.9K4 -

6:08:31

6:08:31

SpartakusLIVE

10 hours agoWARZONE NUKE IS BACK?! || Solo Challenge CHAMPION to start, duos w/ the Dawg later

92.1K1 -

1:00:18

1:00:18

Man in America

12 hours agoBig Pharma’s Empire of Lies Is COLLAPSING as People Turn to Natural Medicine

56K20 -

LIVE

LIVE

Drew Hernandez

14 hours agoGHISLAINE MAXWELL SAYS CLAIMS EPSTEIN WAS INTELLIGENCE ASSET ARE BULLSH*T?!

807 watching -

29:54

29:54

Afshin Rattansi's Going Underground

22 hours agoUkraine: Prof. Anatol Lieven SLAMS Europe’s ‘BLOODY STUPIDITY’ as Trump Negotiates with Putin

31K6 -

15:27

15:27

robbijan

1 day ago $2.45 earnedThe Emperor’s New Labubu & The Spiritual War Behind Everything

52.4K43