Premium Only Content

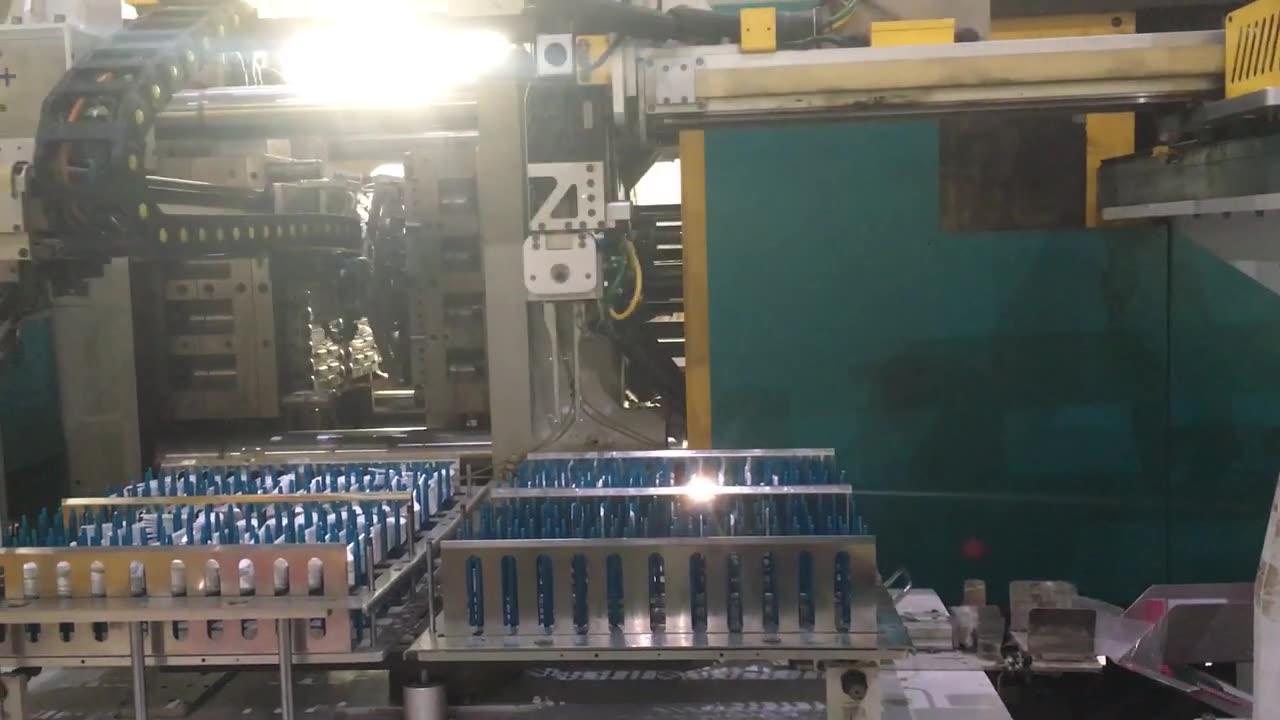

Plastic cutlery Injection Machine

Plastic cutlery Injection Machine

Plastic cutlery injection molding machines are used in the manufacturing process of producing plastic utensils such as forks, knives, and spoons. These machines operate through the injection molding process, which involves melting plastic pellets and injecting the molten material into a mold cavity to form the desired shape. Here is an overview of the key components and steps involved in the plastic cutlery injection molding process:

Key Components of a Plastic Cutlery Injection Molding Machine:

Injection Unit:

This unit is responsible for melting and injecting the plastic material into the mold.

It includes a hopper for holding plastic pellets, a barrel for heating and melting the plastic, and a screw or plunger for injecting the molten plastic into the mold.

Mold:

The mold is a crucial part of the process, as it defines the shape and features of the plastic cutlery.

It consists of two halves (cavities) that come together to form the final product.

Clamping Unit:

The clamping unit holds the mold in place during injection and cooling.

It includes a clamping mechanism to securely close and hold the mold halves together.

Cooling System:

After injection, the plastic inside the mold needs to cool and solidify.

A cooling system helps regulate the temperature and speed up the solidification process.

Ejector System:

Once the plastic has solidified, the ejector system pushes the finished plastic cutlery out of the mold.

Control System:

The control system manages and regulates the entire injection molding process, including temperature control, injection speed, and other parameters.

Plastic Cutlery Injection Molding Process:

Material Loading:

Plastic pellets are loaded into the hopper of the injection molding machine.

Injection:

The plastic pellets are melted in the barrel and injected into the mold cavity.

Cooling:

The molten plastic inside the mold cools and solidifies to take the shape of the cutlery.

Ejection:

The ejector system pushes the finished plastic cutlery out of the mold.

Quality Control:

The produced plastic cutlery undergoes inspection for defects, ensuring quality standards are met.

Packaging:

The final step involves packaging the plastic cutlery for distribution.

When seeking a plastic cutlery injection molding machine, it's essential to consider factors such as the machine's capacity, precision, energy efficiency, and the type of plastic materials it can process. Manufacturers and suppliers of plastic molding machines can provide specific details about their equipment, and you may also explore industry exhibitions and trade shows to learn more about available technologies.

-

UPCOMING

UPCOMING

Barry Cunningham

13 hours agoCHARLIE KIRK MEMORIAL SERVICE FEATURING PRESIDENT TRUMP AND JD VANCE AND MANY OTHERS!

4.64K2 -

22:13

22:13

iCkEdMeL

1 hour agoMass Shooting at Wedding Reception — Witnesses Say Shooter Yelled “Free Palestine”

102 -

0:36

0:36

Danny Rayes

2 days ago $0.40 earnedFacebook Needs To Be Stopped...

1.89K3 -

LIVE

LIVE

Total Horse Channel

16 hours agoAMHA World Show 2025 9/21

1,227 watching -

1:29:02

1:29:02

Game On!

1 day ago $6.26 earnedTHEY'RE BACK! NFL Wise Guys Return For Week 3 BEST BETS!

26.3K2 -

6:16

6:16

China Uncensored

1 hour agoHow Trump Plans on Stopping Russia and China—Without Firing a Shot!

3.7K7 -

33:13

33:13

Ohio State Football and Recruiting at Buckeye Huddle

13 hours agoOhio State Football: 10 Things We Learned Watching Washington's Win over Colorado State

2.25K -

1:14:04

1:14:04

NAG Entertainment

14 hours agoKickback w/ Leon - Rocket League: Road to GC

8.59K -

30:13

30:13

Degenerate Plays

1 hour agoBritish Insults Are Hilarious - Call of Duty: Modern Warfare 2 (2009) : Part 2

3.94K1 -

6:42

6:42

NAG Daily

18 hours agoCharlie Kirk: His Words. His Vision. His Movement.

29.6K26