Premium Only Content

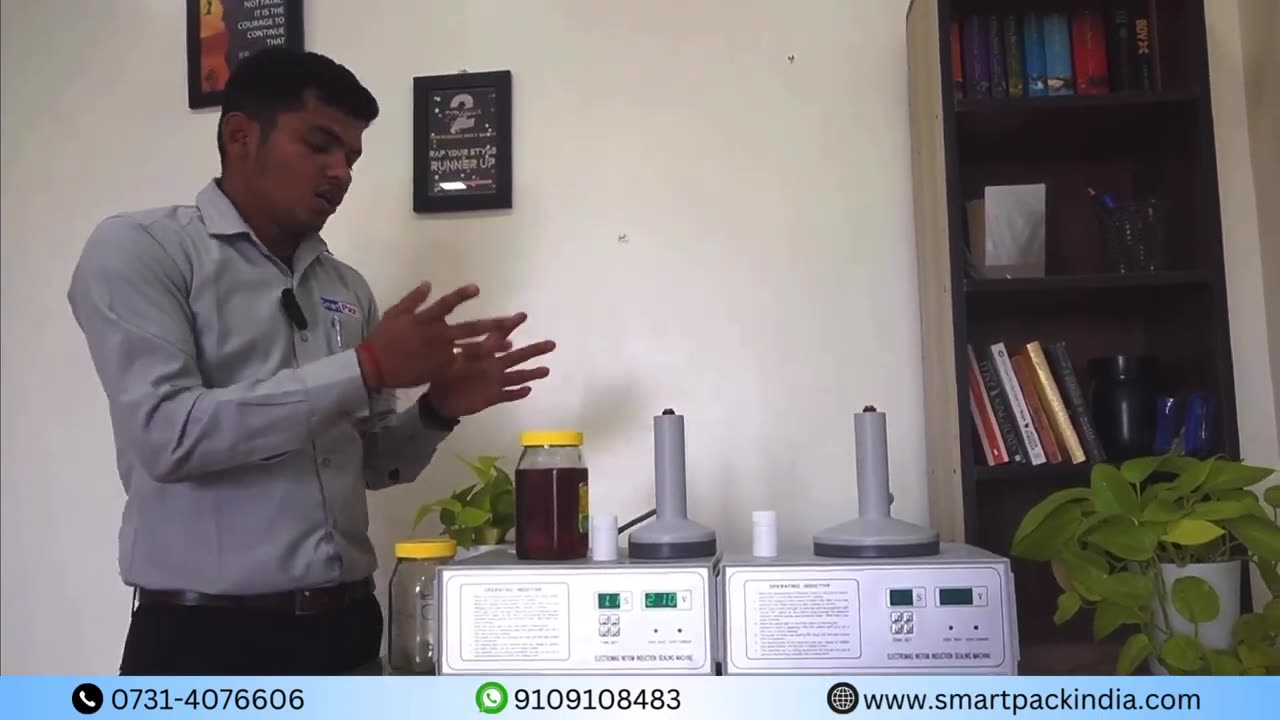

INDUCTION SEALING MACHINE (PACKAGING MACHINE)

Smart packaging is committed to providing sustainable and eco-friendly packaging solutions that not only reduce waste but also offer advanced functionality and efficiency. By integrating sensors, data storage, and communication capabilities into their packaging systems,

An induction sealing machine, also known as an induction cap sealing machine, is a device used to seal containers with a tamper-evident seal using induction heating. It is commonly used in the food, beverage, pharmaceutical, and chemical industries to ensure product safety and extend shelf life.

The induction sealing process involves placing a foil seal over the container's opening, which is then heated by an induction field generated by the machine. The heat melts the polymer coating on the foil, which then bonds to the container's rim, creating a hermetic seal. The induction sealing process is fast, and efficient, and can be used on a variety of container sizes and materials, including glass, plastic, and metal.

Induction sealing machines can be manual or automatic, depending on the production volume and level of automation required. Automatic induction sealing machines are often integrated into packaging lines, with the sealing process synchronized with other packaging operations. Some machines may also be equipped with advanced features, such as automated cap sorting and feeding systems, to further increase productivity.

We feel happy to make our customers satisfied with our products and services in the field of packaging machinery.

-

6:10:35

6:10:35

Grant Cardone

1 day agoHow to Build Wealth in 2025 - Grant Cardone LIVE!

54.2K -

LIVE

LIVE

Nhailed

4 hours agoHalo tourney 4pm EST.

52 watching -

LIVE

LIVE

Phyxicx

1 hour agoBrrrap Pack Halo Tournament! - 6/28/2025

34 watching -

LIVE

LIVE

Sgt Wilky Plays

5 hours agoBRRRAP!!! Pack Halo Classic

19 watching -

1:20:15

1:20:15

Jeff Ahern

6 hours ago $4.93 earnedThe Saturday Show with Jeff Ahern

166K7 -

LIVE

LIVE

Meisters of Madness

4 hours agoThe Halo Classic - 3

113 watching -

LIVE

LIVE

ZWOGs

6 hours ago🔴LIVE IN 1440p! - #MensMentalHealth w/ @crgoodw1n then Halo 3 Tournament w/ Omega - Come Hang Out!

52 watching -

8:43:27

8:43:27

GritsGG

11 hours agoWe Are Winning Every Game! Win Streaking! 👑 2998+ Ws

66.4K -

8:28

8:28

nospeedlimitgermany

3 days ago $4.97 earnedFord Mustang GT 5.0 V8 421 PS Top Speed Drive German Autobahn No Speed Limit POV

54.1K15 -

7:19:07

7:19:07

SilverFox

10 hours ago🔴LIVE - Fox FINALLY plays FORTNITE

35.5K1