Premium Only Content

How A Custom 1911 Is Built

In this latest video from Nighthawk Custom, see the entire process of a pistol going from raw steel to an immaculate custom handgun. Follow the journey of an Agent 2 being built from beginning to end. We take U.S. billet steel and cut it down to size before machining those billets into intentionally oversized parts. Those parts are then individually hand fit by a skilled gunsmith, creating a perfect fit and a truly custom pistol.

From there, the pistol will undergo multiple inspections, making sure that every detail is right. After each part is individually inspected, the pistol will be sent out to finish. Upon returning from finish, the pistol will be reassembled and inspected to ensure no blemishes exist in the finish. It is then that the front and rear sights are installed. Once the sights have been installed, the pistol will be taken out to function test and targeting. Function testing ensures that the pistol will run while targeting sees two or three rounds shot through a single hole. The pistol will then receive a thorough cleaning before heading to our Sales department. One of our experienced account managers will then ship the gun to the dealer or FFL it is intended for.

-

2:30

2:30

Nighthawk Custom

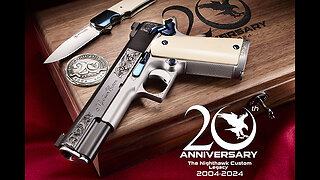

1 month agoNighthawk Custom 20th Anniversary 1911 - A Pistol 20 Years in the Making

109 -

1:47:55

1:47:55

Game On!

15 hours ago $4.69 earnedWhat Was THAT!? Sweet 16 Day 2 Preview and Best Bets!

23.2K4 -

![Elon Musk’s DOGE Team Drops 17 Jaw-Dropping Facts About U.S. Govt Fraud, Waste & Abuse [EP 4495-8AM]](https://1a-1791.com/video/fwe2/44/s8/1/a/Q/3/w/aQ3wy.0kob-small-Elon-Musks-DOGE-Team-Drops-.jpg) LIVE

LIVE

The Pete Santilli Show

16 hours agoElon Musk’s DOGE Team Drops 17 Jaw-Dropping Facts About U.S. Govt Fraud, Waste & Abuse [EP 4495-8AM]

1,138 watching -

1:09:22

1:09:22

JULIE GREEN MINISTRIES

3 hours agoLIVE WITH JULIE

75.9K129 -

21:01

21:01

Shea Whitney

3 hours ago $0.25 earned30 *EPIC* Amazon SPRING PRIME DAY Deals PART 2!🔥

7.74K -

9:32

9:32

IsaacButterfield

5 hours ago $0.19 earnedEvil Men in JAIL With Women...

4.96K4 -

12:22

12:22

NinjaGamblers

3 hours ago $0.14 earnedHow to Win at Blackjack with the Reverse D'Alembert Strategy

4.5K1 -

19:15

19:15

Melonie Mac

20 hours agoCrystal Dynamics laid off a bunch of people - what does this mean for Tomb Raider?

35.8K40 -

12:48

12:48

Degenerate Jay

1 day ago $2.53 earnedThe Fox X-Men Are Back! Avengers Doomsday Secrets Revealed!

17.5K6 -

28:29

28:29

CatfishedOnline

1 day agoFamily Has To Stop Dad From Marrying A Romance Scammer!

29.7K8