Premium Only Content

#157 Selective Laser Sintering (SLS)

Selective Laser Sintering (SLS) is an additive manufacturing or 3D printing technology used to create three-dimensional objects by selectively fusing or sintering layers of powdered material. It is a popular method for producing complex and durable parts, particularly in industries such as aerospace, automotive, healthcare, and product design. Here's how SLS works and some of its key features:

Process: SLS begins with a bed of powdered material, typically a thermoplastic polymer, metal, or ceramic. A high-power laser selectively fuses the powdered material layer by layer, according to a 3D computer-aided design (CAD) model.

Layer-by-Layer Fusion: The laser is directed to the specific areas of each layer where fusion is required, based on the design. As the laser passes over the powdered material, it heats it to the point of sintering, causing the particles to fuse together and form a solid layer.

Powder Bed: After each layer is sintered, a new layer of fresh powder is spread over the previous one. This process is repeated iteratively until the entire object is built up, with each layer fusing to the layer below it.

Support Structures: SLS doesn't require support structures like some other 3D printing methods (e.g., Fused Deposition Modeling or FDM) because the unsintered powder acts as support for the object during printing. This reduces the need for post-processing work to remove supports.

Material Versatility: SLS can use a wide range of materials, including various polymers (e.g., nylon, polyamide, PEEK), metals (e.g., aluminum, titanium), and ceramics. The choice of material depends on the specific application and desired properties of the final object.

Complex Geometries: SLS is well-suited for producing complex and intricate designs, including parts with internal channels or structures that would be difficult or impossible to create using traditional manufacturing methods.

Durability: SLS-produced parts are known for their durability and strength. This makes them suitable for functional prototypes, end-use parts, and components subjected to mechanical stress.

Accuracy and Resolution: SLS can achieve high levels of accuracy and resolution, allowing for fine details and tight tolerances in printed objects.

Post-Processing: While SLS parts typically require less post-processing than some other 3D printing methods, they may still need surface finishing or additional treatments depending on the specific application.

Production Applications: SLS is used in various industries for prototyping, custom manufacturing, and low to medium-volume production. It's particularly valuable for rapid prototyping, where multiple design iterations can be quickly produced and tested.

One of the advantages of SLS is its ability to create functional, end-use parts directly from digital designs, which can significantly reduce lead times and production costs. However, it can be more expensive than some other 3D printing methods due to the specialized equipment and materials required. Despite this, its versatility and ability to produce high-quality parts make it a popular choice for a wide range of applications.

www.antharas.co.uk/ companies website or top book distributors!

#BusinessStrategy

#Entrepreneurship

#Leadership

#Management

#Marketing

#Finance

#Startups

#Innovation

#Sales

#SmallBusiness

#CorporateCulture

#Productivity

#SelfDevelopment

#SuccessStories

#PersonalBranding

#Networking

#Negotiation

#BusinessEthics

#TimeManagement

#GrowthStrategies

#MarketAnalysis

#BusinessPlanning

#FinancialManagement

#HumanResources

#CustomerExperience

#DigitalTransformation

#Ecommerce

#SocialMediaMarketing

#BusinessCommunication

#ChangeManagement

-

14:15

14:15

AV

1 year ago#1151 Press release - AUKUS real-time AI trials

312 -

LIVE

LIVE

SpartakusLIVE

4 hours agoBattlefield 6 - REDSEC w/ The Boys || WZ or Arc Raiders Later?

5,190 watching -

2:50:16

2:50:16

TimcastIRL

3 hours agoSupreme Court May OVERTURN Gay Marriage, SCOTUS Hearing Set For TOMORROW | Timcast IRL

155K75 -

LIVE

LIVE

Barry Cunningham

4 hours agoBREAKING NEWS: PRESIDENT TRUMP HOSTS A STATE DINNER | FOX NATION PATRIOT AWARDS!

6,531 watching -

LIVE

LIVE

Alex Zedra

2 hours agoLIVE! New Game | The See Us

158 watching -

LIVE

LIVE

ThisIsDeLaCruz

1 hour agoOn The Road With Pantera

111 watching -

LIVE

LIVE

meleegames

1 hour agoMelee Madness Podcast #58 - They Changed What ‘It’ Was & It’ll Happen to You

37 watching -

megimu32

2 hours agoOn The Subject: Why K-Pop Demon Hunters Feels Like 90s Disney Again

9858 -

1:38:28

1:38:28

Glenn Greenwald

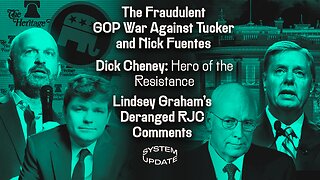

6 hours agoThe Fraudulent GOP War Against Tucker and Nick Fuentes; Dick Cheney: Hero of the Resistance; Lindsey Graham's Deranged RJC Comments | SYSTEM UPDATE #544

82.9K91 -

LIVE

LIVE

ThePope_Live

1 hour agoRedsack with the boys Cheap, Jah and Nova!

108 watching