Premium Only Content

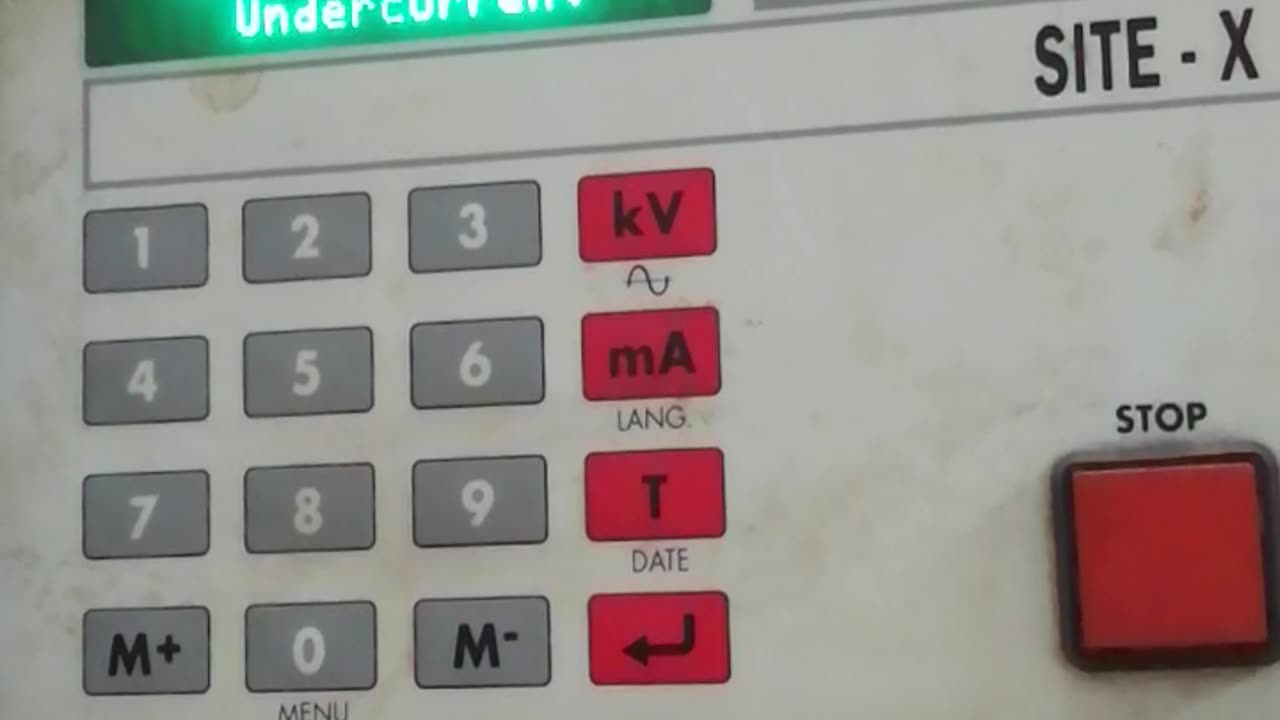

X ray machine repairing and calibration

Initial Assessment: The technician begins by diagnosing the issue. This might involve interviewing staff to understand any problems they've noticed and conducting preliminary tests.

Safety Precautions: Ensuring the safety of both the technician and others in the vicinity is paramount. This includes shutting down the machine, posting warning signs, and using appropriate personal protective equipment.

Accessing the Machine: Depending on the issue, the technician may need to access the X-ray machine's components. This could involve removing panels or covers.

Diagnostic Testing: Specialized tools and equipment are used to diagnose the specific problem. This might involve testing the X-ray generator, the control panel, or other components.

Repair or Replacement: Once the problem is identified, the technician can proceed with repairing or replacing the faulty components. This could involve soldering, rewiring, or replacing electronic parts.

Calibration: After the repair, the X-ray machine needs to be calibrated to ensure it operates accurately and safely. This involves adjusting settings and conducting test runs.

Quality Assurance: Rigorous testing is conducted to ensure the X-ray machine is functioning correctly. This includes verifying that radiation levels are within acceptable limits and that image quality is optimal.

Documentation: Detailed records of the repair process, including what was done and any replaced components, should be maintained for regulatory compliance and future reference.

Safety Checks: Before the machine is put back into regular use, additional safety checks are performed to ensure there are no radiation leaks or other safety hazards.

Training: Staff who operate the X-ray machine should be trained on any changes or updates made during the repair process.

Final Approval: Once the X-ray machine passes all safety and performance tests, it can be approved for regular use again.

-

15:34

15:34

Misha Petrov

12 hours agoReacting To TikTok’s Most DELUSIONAL Takes!

1.29K4 -

1:52:24

1:52:24

Squaring The Circle, A Randall Carlson Podcast

1 day ago#032 Flournoy Holmes' Artwork Helped Define The Southern Rock Phenomenon of The Early 1970's

1.83K2 -

19:56

19:56

inspirePlay

1 day agoWalking with Lions & Facing Africa’s Wild Side | Safari Adventure with the Grid Championship Crew!

7 -

10:50

10:50

RTT: Guns & Gear

1 day agoBudget Friendly Carry 2011: EAA Girsan Brat 2311

2181 -

3:49:06

3:49:06

Alex Zedra

13 hours agoLIVE! New Game | Nuclear Nightmare

87.1K11 -

25:08

25:08

MYLUNCHBREAK CHANNEL PAGE

1 day agoUnder The Necropolis - Pt 2

270K61 -

1:45:59

1:45:59

Spittin' Chiclets

1 day agoCanadian Chokejob - Game Notes Live From Chicago - 12.28.2024

251K31 -

9:18

9:18

Space Ice

22 hours agoThe Guyver - Alien Bug Suits, Exploding Dragons, & Mark Hamill - Weirdest Movie Ever

159K25 -

9:31

9:31

Silver Dragons

1 day agoSilver Has Failed - Can it Set the Record Next Year? THIS BANK SAYS YES!

1.44K2 -

7:08

7:08

GBGunsRumble

16 hours agoGBGuns Range Report 28DEC24

206