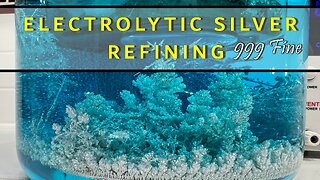

Nano Colloidal Silver Generation

30 Volts, 1 liter distilled water with SodiumCarbonate to a 100TDS, 10 oz pure silver bar as anode, #12ga pure silver wire as cathode, magnetic stirring. Cover from UV LIGHT. Math: 1 liter x 20 ppm desired x 15 and that divided by constant milli-amps current set for the process = minutes of production time. I use 20 milliamps of current. That means I need to shut electrolysis power off after 15 minutes. (300/20=15) Fraday's Law. 20ppm of ionic silver was made. I want particles in the 1 - 10 nanometer range so I must use a specific reducing agent at a specific amount to make that happen. I add 1ml of double filtered green tea water extract slowly!, some ions will reduce already. Now put into microwave for 2 minutes. That is about 70 Centigrade. Back to stirring now. It has turned into the most beautiful yellow. Filter with clean coffee filter. Let cool off, never refrigerate. TDS when room temperature should be 100, same as start. All ionic silver was converted. Yellow = 3nm - 30 nm size AGNPs. You could put an additional gelatin cap on these particles which could make it even better. Another subject. Good work! ☺

Colloidal silver test with laser light in darkness showing strong beam in the liquid. Tyndall effect.

-

2:05

2:05

Stroppy

1 year agoHow I Make Colloidal Silver

5897 -

0:53

0:53

loooping8

2 years ago $0.17 earnedMy compact 3 colloidal silver generator

1.21K -

6:15

6:15

s1mpletruths

11 months agoMaking 200ml of 2000ppm colloidal silver honey.

1021 -

13:49

13:49

Anthony Thomas Fine Metals & Gems

8 months ago $0.15 earnedExperimental Silver Cell

881 -

8:18

8:18

maersknet

10 months agoColloidal silver water 1 liter 10 ppm

524 -

20:55

20:55

RainCountryHomestead

10 months ago $7.29 earnedHow to Make Colloidal Silver Soap

9.35K30 -

1:19:21

1:19:21

bigwindy

11 months agoNano Minerals - Nano Silver/ Silverwater

53 -

1:19:13

1:19:13

All videos

3 months agoColloidal Silver Teaching Demonstration by Brother Steve

351 -

46:52

46:52

Alter Ether

5 months agoSUPER SILVER! THE MANY BENEFITS OF COLLOIDAL SILVER! POWER UP!

4792 -

0:58

0:58

AmericanLibertySilver

3 months agoColloidal Silver vs Structured Silver

21