I turn a Nut into a tiny Adjustable Wrench

In this video I'm turning a stainless steel M20 nut into a tiny adjustable wrench. All three parts are completely made out of one single nut. First I turned the thread and the hexagon away on the lathe. After cutting a slit into it I was able to open it up with the help of a torch. A few heats later I had a very straight and flat piece of stainless steel. I first went then on the milling machine and milled the whole part to the final width of the wrench. I then cut of a piece with the hacksaw to make the body out of it. With a tiny t-slot endmill I was able to mill the t-slot very nicely with a very low feedrate and a lot of oil. After milling the square hole and drilling the deep 2.1mm hole I started to shape the outer contour. Then I moved on by making the movable part of the wrench. I milled it all in one operation with very careful steps to not risk and chatter marks or whatsoever. After filing the square bit round I sanded the rectangular part until it fitted nicely into the body. I then cut the M2 thread and cut the piece off with the hacksaw, assembled it with the body and sanded both parts flush. Then I started rounding off all edges with needle files, sandpaper and finished it with very fine steel wool for a brushed finish. All what's left to do now was making the knurled adjuster nut. For that I forged the remaining of the nut into a square piece, which I could clamp in the four jaw chuck on the lathe. I turned it round, supported it with a live center, put the knurling onto it, drilled and tapped the hole, chamfered it and parted it off. Then it was just a matter of quickly assembling the three pieces.

This was a very cool little project for me. I really like how it turned out. It's a very cool little item in my opinion.

New Video Every Tuesday And Saturday At 6pm ET

-

2:10:26

2:10:26

Roseanne Barr

2 days ago $85.81 earnedDanger Close with Patrick Byrne Part 2 | The Roseanne Barr Podcast #54

180K232 -

37:25

37:25

Squaring The Circle w/ Randall Carlson

1 day ago#010 The Cosmos Speaks: The Tunguska Event Pt.1 - Squaring the Circle: A Randall Carlson Podcast

56.7K24 -

3:15

3:15

scoutthedoggie

1 day agoAirsoft Sniper Silverback TAC-41

69.7K10 -

7:15

7:15

Brad Polumbo

1 day ago $0.02 earnedCommunist TikToker gets exposed 🤣 (as total hypocrite!)

69.4K43 -

23:06

23:06

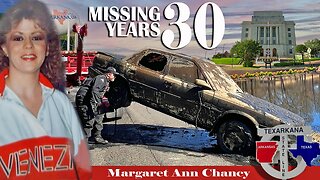

Exploring With Nug

1 day ago $0.04 earned30 Years Later: The Nurse Who Vanished Without a Trace

65.3K3 -

18:23

18:23

DepressedGinger

1 day ago $0.13 earnedDems have *HUGE* fight over who should run, start turning on each other

70.6K64 -

24:00

24:00

CarlCrusher

2 days agoReports of Disappearing Ghost Orbs and Shapeshifting Skinwalkers

52.7K10 -

13:03

13:03

JoBlo Originals

1 day agoSucker Punch - NOT As Bad As You Thought?

53.1K19 -

10:38

10:38

Tactical Advisor

1 day agoModern Lever Actions Overview

46.1K9 -

29:11

29:11

MYLUNCHBREAK CHANNEL PAGE

1 day agoExposing Chicago's Tunnel System?

40.3K80