Premium Only Content

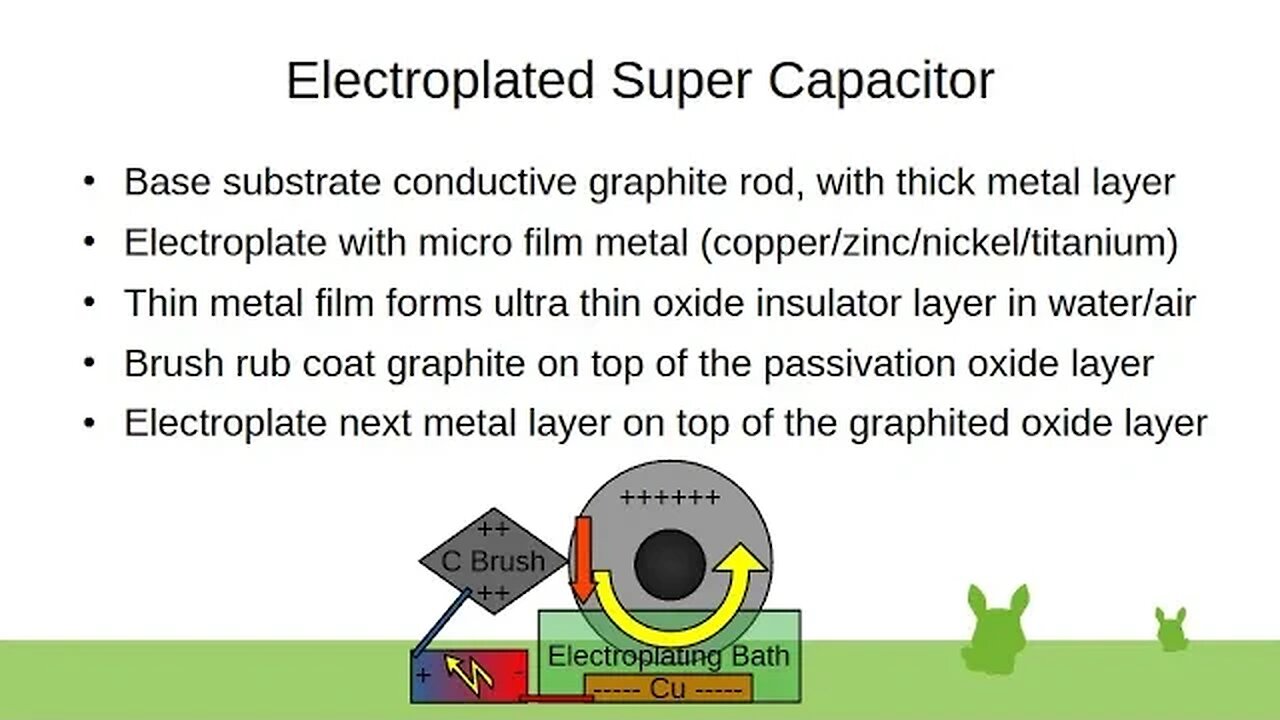

Electroplated Super Capacitor

Electroplating process for super atom thick process for graphite rod super capacitors (non-electrolytic solid state thin film super capacitor, no dual layer, direct capacitance, central rod can be even charred wood). Capacitor does not explode because of water steaming at above 100C temperatures. Brush rub coat graphite on top of the thin passive oxide layer on the electroplate to get it conductive, then electroplate then next thin metal layer, into a super packed super capacitor. After coating with graphite, the surface becomes nearly frictionless, not applying more graphite, like saturating/limiting the graphite layer height, minimizing the total layer volume. The super capacitor grows on the spinning graphite rod cylinder on a production line or as even small batches or individual parts. Can be used to make metal foils in sheet rolls, for metal-air fuel cells. Metals detach from plastic mold/support by heating the metal close to the plastic melting point.

-

0:40

0:40

Jkauppafi

12 hours agoUltra-Light Box-Arrow-Batwing Drone-Kite-Plane Frame (Battery)

-

LIVE

LIVE

Lofi Girl

2 years agoSynthwave Radio 🌌 - beats to chill/game to

355 watching -

4:30:47

4:30:47

BigN1ck

6 hours agoPhasmo and chill

11.3K1 -

10:03

10:03

The Pascal Show

22 hours ago $8.38 earnedNEW STATEMENT! D.A. Breaks Silence Since Emmanuel Haro Presser... Trying To Shut Up Social Media?!

29.1K5 -

LIVE

LIVE

LethalPnda

3 hours ago🔫 "Bullets, Bad Decisions & Farlight 84" I @Mystivis

181 watching -

21:22

21:22

GritsGG

18 hours agoPlugged in MnK on Warzone & We Hit Shots!

181K5 -

1:23:30

1:23:30

TruthStream with Joe and Scott

2 days agoJaime Harlow is back! #483

28.4K22 -

1:32

1:32

Gaming on Rumble

2 days agoWhat is the Rumble Creator Program?!?! | Lvl UP

74.3K5 -

10:34:09

10:34:09

Rallied

18 hours ago $22.42 earnedSolo Challenges ALL DAY

273K9 -

1:39:43

1:39:43

Brandon Gentile

2 days agoTOP Money Expert: Bitcoin Will Keep Setting All-Time Highs Beyond $10m

26.6K3