Premium Only Content

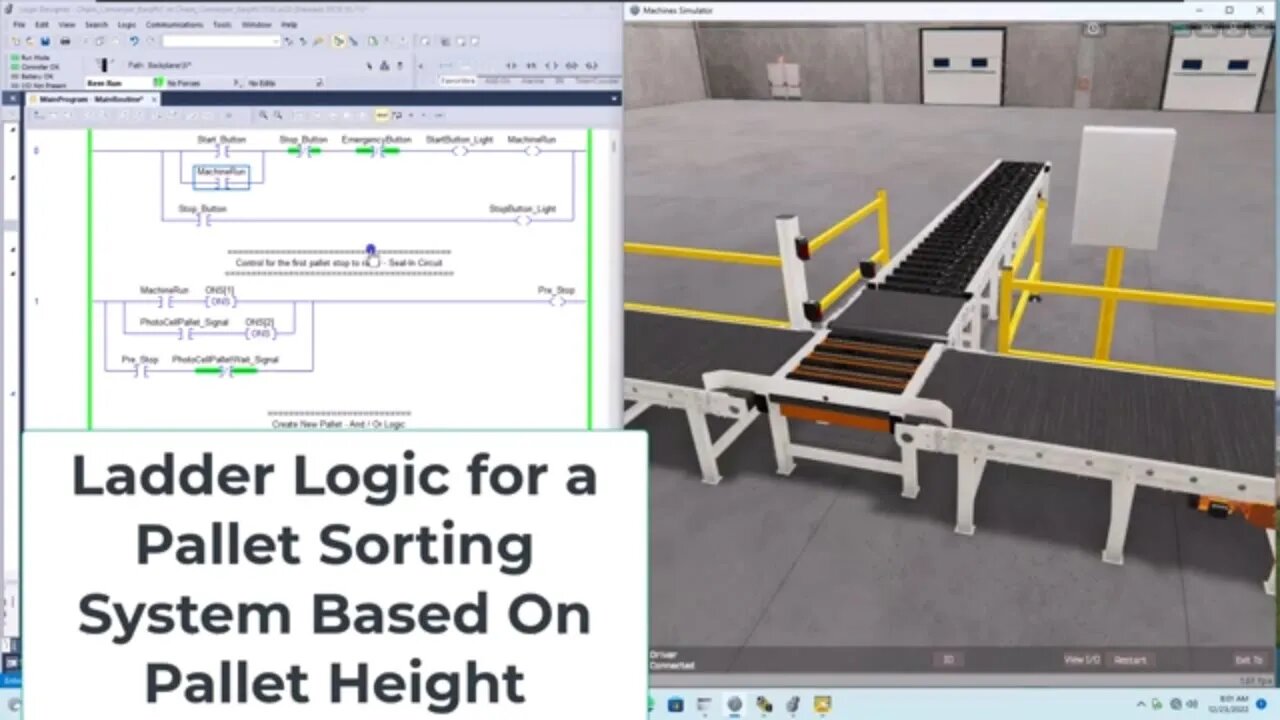

PLC Ladder Logic for a Pallet Sorting Conveyor Based on Pallet Height

PLC Ladder Logic for a Pallet Sorting Conveyor system

Programmable Logic Controllers (PLCs) are a crucial component in many industrial automation systems, and ladder logic is a popular programming language used to create control programs for PLCs. In this article, we will explore how ladder logic can be used to control a pallet sorting conveyor system.

A pallet sorting conveyor system typically consists of multiple conveyor belts and sensors that are used to sort incoming pallets based on certain criteria, such as size or destination. The PLC is responsible for receiving input from the sensors, making decisions based on this input, and activating the appropriate conveyor belt to sort the pallet.

To control such a system using ladder logic, we first need to define the input and output (I/O) points for the PLC. The inputs may include sensors that detect the presence of a pallet on the conveyor, as well as sensors that measure the size or destination of the pallet. The outputs may include the control signals for the conveyor belts, as well as any indicators or displays that are used to communicate the status of the system to the operator.

Next, we can create a ladder logic program that defines the logic for sorting the pallets. This may involve creating multiple rungs on the ladder, each of which represents a different sorting decision. For example, one rung may be used to sort pallets based on size, while another rung is used to sort pallets based on destination.

To create a rung, we can use logical operators such as AND, OR, and NOT to define the conditions that must be met in order for the rung to be activated. For example, we might use an AND operator to specify that a pallet must be detected by both a size sensor and a destination sensor in order to be sorted by a particular conveyor belt.

Once the ladder logic program has been created, it can be uploaded to the PLC and tested to ensure that it is functioning as intended. If any errors are detected, the program can be modified and re-uploaded until the system is operating correctly.

In conclusion, ladder logic is a powerful tool for controlling a pallet sorting conveyor system using a PLC. By defining the input and output points and creating a logical program using logical operators, we can create a control system that accurately sorts incoming pallets based on various criteria.

0:00 Intro

0:30 Explaining the Ladder Logic

7:50 Running the Pallet Sorting System

8:05 Watching the Ladder Logic control the machine

10:55 Testing Machine E-stop

11:20 Machine Start with proper recovery

Thank you for watching the video.

Learn, Implement, Succeed

Visit:

https://www.allen-bradley-plc-training.com/

Other social media:

LinkedIn: https://www.linkedin.com/in/shane-welcher-sr/

Facebook: https://www.facebook.com/OnlinePLCSupport

#ladderlogic #plc #plcLadderLogic #ladderdiagram

-

2:12

2:12

Shane Welcher

2 years agoPIDE 4 to 20MA signal Reverse Reacting

106 -

LIVE

LIVE

Mally_Mouse

22 hours ago🎮 Let's Play!!: Stardew Valley pt. 33

197 watching -

LIVE

LIVE

VapinGamers

1 hour agoForlight 84/Fortnite: Rum Bot Testing - Gaming, Coding and Other Things - !rumbot !music

52 watching -

LIVE

LIVE

OhHiMark1776

3 hours ago🟢 11-21-25 ||||| Two Morrows make a Day-to-Day? ||||| Livestream (2025)

69 watching -

9:57:30

9:57:30

GrimmHollywood

10 hours ago🔴LIVE • GRIMM HOLLYWOOD x SILVER FOX • GOLDEN YEARS • FINAL DAY • FLARE RACE • ARC RAIDERS •

1.4K1 -

1:11:24

1:11:24

The Daily Signal

4 hours ago $1.33 earned🚨BREAKING: Democrat Steals $5 Million from FEMA, Trump-Mamdani Meeting Gets Bizarre

3.7K2 -

1:02:11

1:02:11

BonginoReport

6 hours agoJ.D. Vance Threatens to Kill JD Vance?! - Nightly Scroll w/ Hayley Caronia (Ep.183)

90.9K35 -

3:09:50

3:09:50

Nerdrotic

16 hours ago $12.50 earnedWarner Bros Fire Sale! | Last Ronin CANNED | WICKED For Good REVIEW - Friday Night Tights 381

36.9K9 -

2:58:21

2:58:21

Akademiks

3 hours agoMeg Thee Stallion Back LYING again? Offset vs Finesse2x. 6ix9ine house robbed.. HERES WHO DID IT

16.7K -

LIVE

LIVE

SpartakusLIVE

3 hours agoFriday Night HYPE w/ YOUR King of Content

159 watching