Premium Only Content

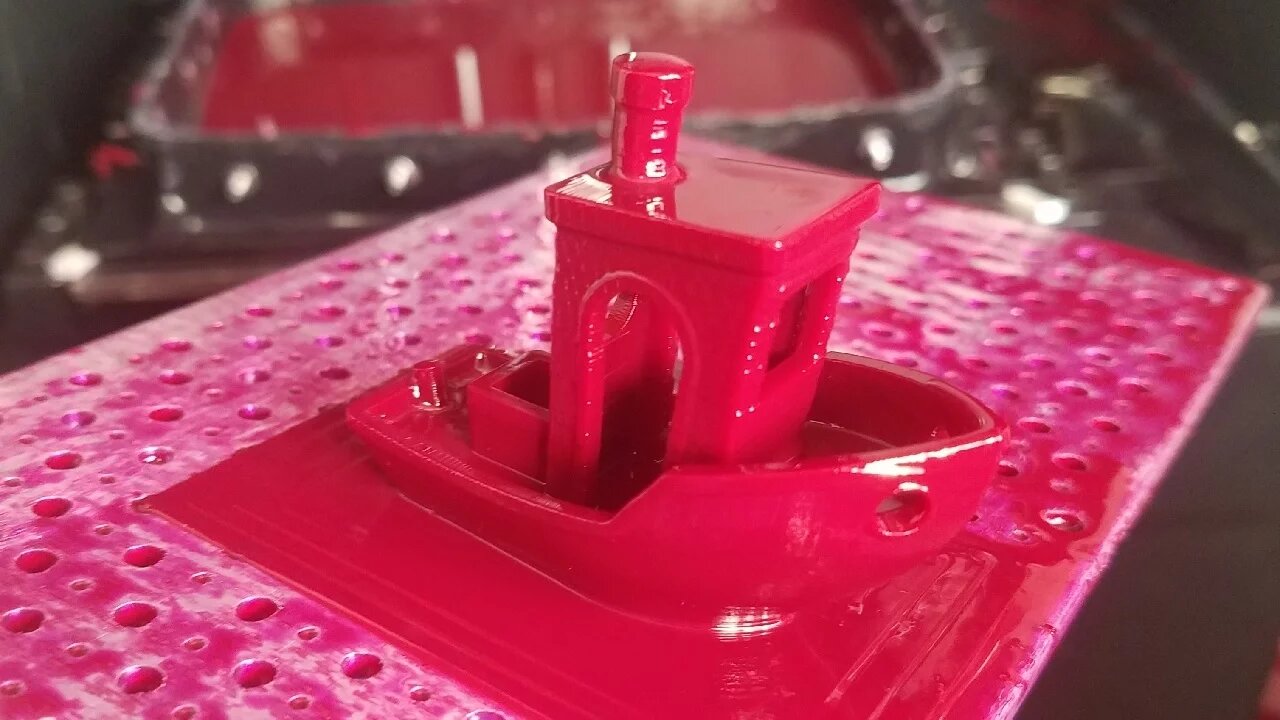

Improve Build Plate Adhesion on Your 3D Printer

We've all been there, failed print after failed print. I want to show you some simple improvements to nearly eliminate print failures from parts separating from the build platform.

#garagescience #maker #doityourself

I managed to modify the build platform on my DLP 3Dprinter to include a large array of closely spaced holes to not only allow resin to pass through the plate and thereby lowing the separation forces but to also allow resin to cure into the holes slightly and increase the adhesion of the part to the build platform.

There is definitely a lot of patience that goes into making a modification like this you can modify your printer and it'll look almost like a CNC mill did it.

I also created a handy tool to easily separate parts without needing a scraper, I'll go over how to create this tool in the video.

The third aspect of this improvement is an overview on creating custom rafts to print parts onto. Since many resins tend to warp and curl on long thin edges (especially on overcured areas) such as the rafts used to attach parts to a printer build plate, having a graduated raft helps to significantly reduce the chances of part separation due to warping on the edges of the raft.

If you made it this far through the video description then you probably had the patience to stick all the way through the video. I applaud your loyalty to my humble Youtube channel. If you haven't already, remember to subscribe and share this video with other 3D Printer lovers. Be sure to like this video as well and leave me a comment about anything I can improve on future videos.

Check me out on FB here: https://www.facebook.com/GarageScience/

I am also on instagram @garage_science

-

58:18

58:18

Flyover Conservatives

1 day agoThe Truth About Halloween that You DIDN’T Know - Holiday Special - Historian Bill Federer | FOC SPECIAL Show

51K7 -

3:10:46

3:10:46

Ellie_roe

7 hours agoEllie and Errys Halloween Spooktacular || Random Horror Games

24.2K1 -

50:27

50:27

Sarah Westall

9 hours agoBig Banks Caught Rigging Market, IMF tells World to “Buckle Up” w/ Andy Schectman

43.6K17 -

13:54

13:54

Degenerate Jay

16 hours ago $1.15 earned5 Best Superhero Movies To Watch On Halloween

22.9K5 -

59:03

59:03

NAG Podcast

9 hours agoSarah Fields: BOLDTALK W/Angela Belcamino

39.4K9 -

1:21:41

1:21:41

Glenn Greenwald

11 hours agoGlenn Takes Your Questions: On the Argentina Bailout, Money in Politics, and More; Plus: Journalist Jasper Nathaniel on Brutality and Settler Attacks in the West Bank | SYSTEM UPDATE #541

92K47 -

3:10:08

3:10:08

Barry Cunningham

9 hours agoPRESIDENT TRUMP TO USE NUCLEAR OPTION? FOOD STAMPS END! | SHUTDOWN DAY 31

55.6K45 -

1:06:56

1:06:56

BonginoReport

17 hours agoThe Battle Between Good & Evil w/ Demonologist Rick Hansen - Hayley Caronia (Ep.168)

105K39 -

1:12:57

1:12:57

Kim Iversen

11 hours agoBill Gates Suddenly Says “Don’t Worry About Climate Change”?

94.1K67 -

1:05:12

1:05:12

Michael Franzese

11 hours agoI Waited 50 Years to Tell You What Happened on Halloween 1975

47.6K20