Premium Only Content

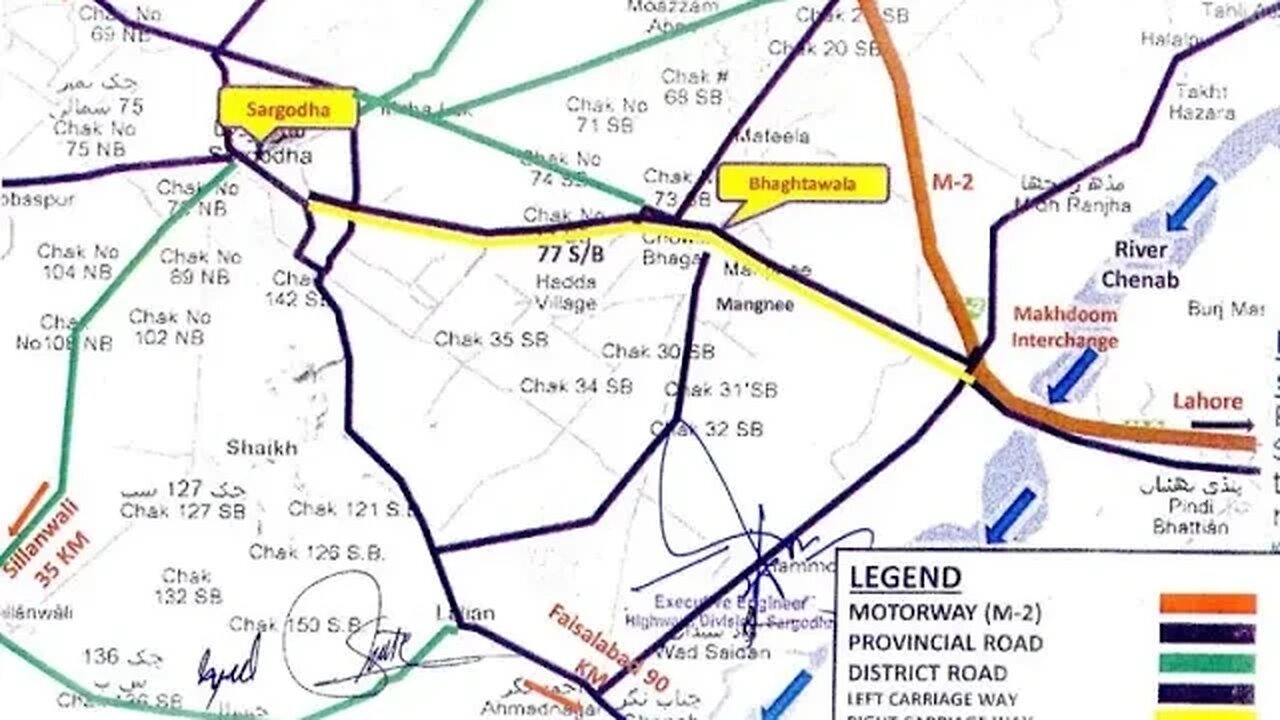

Rehabilitation Of Dualized Road from Sargodha to Makhdoom Interchange (M2) L=42 Km (

Rehabilitation Of Dualized Road from Sargodha to Makhdoom Interchange (M2) L=42 Km (Right Carriage Way), District Sargodha - Roads

Project Title Rehabilitation Of Dualized Road from Sargodha to Makhdoom Interchange (M2) L=42 Km (Right Carriage Way), District Sargodha - Roads

Scheme No. 01332104176

GS NO. 2361 (2022-23)

Location Sargodha to Makhdoom Interchange (M2)

P&DB Sector Infrastructure Development

ADP Sector Infrastructure

Sub-Sector Roads

Sponsoring Ministry/ Agency C&W Department

Execution Agency C&W Department

Operation & Maintenance C&W Department

PC-I Cost Rs. 1636.00 million (28-Sep-2021)

Administrative Approval 28-Sep-2021

Actual Cost / Expenditure Rs. 712.72 million

Planned Start Date 28-Sep-2021

Planned End Date 30-June-2025

Actual Start Date 28-Sep-2021

Gestation Period 03 Years & 09 Months

Beneficiaries General Public & Transporters

% Financial Utilization 44%

Contractor M/s Tayyab Manzoor Tarrar

Supervisory Consultant ESSIR

Design Consultant C&W Department

Design Life Period Ten-years

Date of Visit 13-September-2022

PSDP No

Focal Person Executive Engineer (Highway, Jhelum)

4. Observations

4.1 Schedule:

1. The scheme was ahead of schedule as the physical progress of work was observed to be more than the planned progress (Table 8, Figure 5).

• Planned Physical Progress: 28% as of Sep 2022

• Actual Physical Progress: 35%

• Actual Financial Progress: 44%

Due to difference in the physical and financial progress, the cost of the project may be enhanced by 10% as shown by variance at completion in Table 7 under Earned Value Analysis.

4.2 Cost

2. The funds allocated for financial year 2023-24 are 54% of PC-I phasing as shown in Table 5 which may result in delayed completion of the project.

3. The financial utilization of FY 2022-23 is 88% in the first quarter therefore further funding is required to complete the project as soon as possible as shown in Table 5.

4.3 Risks and Constraints:

4. The difference in physical and financial progress may result enhanced project cost and it may also cause price escalation.

4.4 Scope

5. The project informatory board is required to be fixed at site of work.

6. The length of the road as of project nomenclature was observed to be 42Km. but as per agreement, the project length is 41.50Km. While as of satellite measurement illustrated in the Annex-A, the project length observed to be 41Km. The sponsoring/executing agency need to justify the difference in length of road as of nomenclature, contract agreement and satellite measurements (Annex-A).

7. The protected U-Turns needed to be provided to avoid accidents, as shown in Figure 6.

8. The un-authorized U-turns are needed to be closed to avoid accidents, as shown in Figure 7.

9. The bitumen spray coat is required to be cleaned from the surface of New Jersey Barrier, as shown in Figure 8.

10. The shoulders are needed to be compacted and vegetation needed to be removed, as shown in Figure 9.

11. A sensor wire is needed to be fixed to ensure the level and required thickness of Asphaltic base coarse, as shown in Figure 10.

12. The workers are required to provide with PPEs while safety measures are needed to be taken during asphalt paving, as shown in Figure 12.

13. The safety ribbons and safety barriers are needed to be used during work instead of wooden pieces, as shown in Figure 13. HSE measures need to be taken as per NEBOSH/OSHA Guidelines.

14. The construction joint of the Asphalt is needed to be aligned in order to improve the riding quality, as shown in Figure 14.

15. The side slope is required to be as per standard drawings to ensure the water drainage from the road while the drain is needed to be constructed at the end of property line to avoid encroachments on right-of-way, as shown in Figure 15.

16. The Los Angeles Abrasion Machine present at site was unfunctional and needed to be used to ensure quality of the WBM material, as shown in Figure 16.

17. The core cutter machine needed to be fixed as it was not provided for checking the asphalt thickness, as shown in Figure 17.

18. The calibration certificates and calibration stickers are required to be fixed on the field laboratory equipment, as shown in Figure 18.

19. The Housekeeping required in the Lab, as shown in Figure 19.

20. The filter paper required to be used having weight as per specification, as shown in Figure 20.

21. The non-functional compressive strength checking machine needed to be fixed, as shown in Figure 21.

22. The cost of excavated kurb-stones from existing center median needed to be deducted, as shown in Figure 22.

23. The right-of-way needed to be cleared, as shown in Figure 23.

24. The Electric poles needed to be shifted away from main carriage way, as shown in Figure 24.

25. The encroachments and plantations needed to be removed from main carriage way, as shown in Figure 25.

26. The encroachments in the asphaltic road are needed to be removed, as shown in Figure 26.

-

LIVE

LIVE

Sean Unpaved

1 hour agoQuarterbacks, Coaches, & Contracts: Sanders' Draft Drama, Meyer vs. Harbaugh, & McLaurin's Big Deal

131 watching -

2:11:45

2:11:45

Steven Crowder

4 hours agoDonald Trump Vs American Crime: Chicago is Next & Libs Are Freaking Out

183K180 -

LIVE

LIVE

Grant Stinchfield

35 minutes agoDemocrats Try to Turn California Into Predator Playground with Proposed "Child Predator Dream Bill"

172 watching -

LIVE

LIVE

Rebel News

59 minutes agoCdn troops in Ukraine? Poilievre backs self-defence, Hamas thugs cancel Ottawa Pride | Rebel Roundup

350 watching -

DVR

DVR

Neil McCoy-Ward

1 hour ago⚠️ OUTRAGE! What They Just Announced For YOUR HOME!!! 🚨

3.82K -

LIVE

LIVE

IrishBreakdown

2 hours agoNotre Dame and Miami Set To Reignite Intense Rivalry

825 watching -

LIVE

LIVE

The Charlie Kirk Show

1 hour agoChicago Next! + The Blue Slip Problem | Sen. Tuberville, Alex Clark | 8.25.2025

3,171 watching -

1:20:52

1:20:52

Benny Johnson

3 hours ago🚨Trump LIVE Now: Signs Executive Order ENDING Cashless Bail | Dem Cities PANIC, Which City NEXT?...

39K30 -

1:31:26

1:31:26

The White House

4 hours agoPresident Trump Signs Executive Orders, Aug. 25, 2025

26K17 -

LIVE

LIVE

The Mel K Show

2 hours agoMORNINGS WITH MEL K - Starving the Globalist Funded Color Revolution in America 8-25-25

790 watching