Premium Only Content

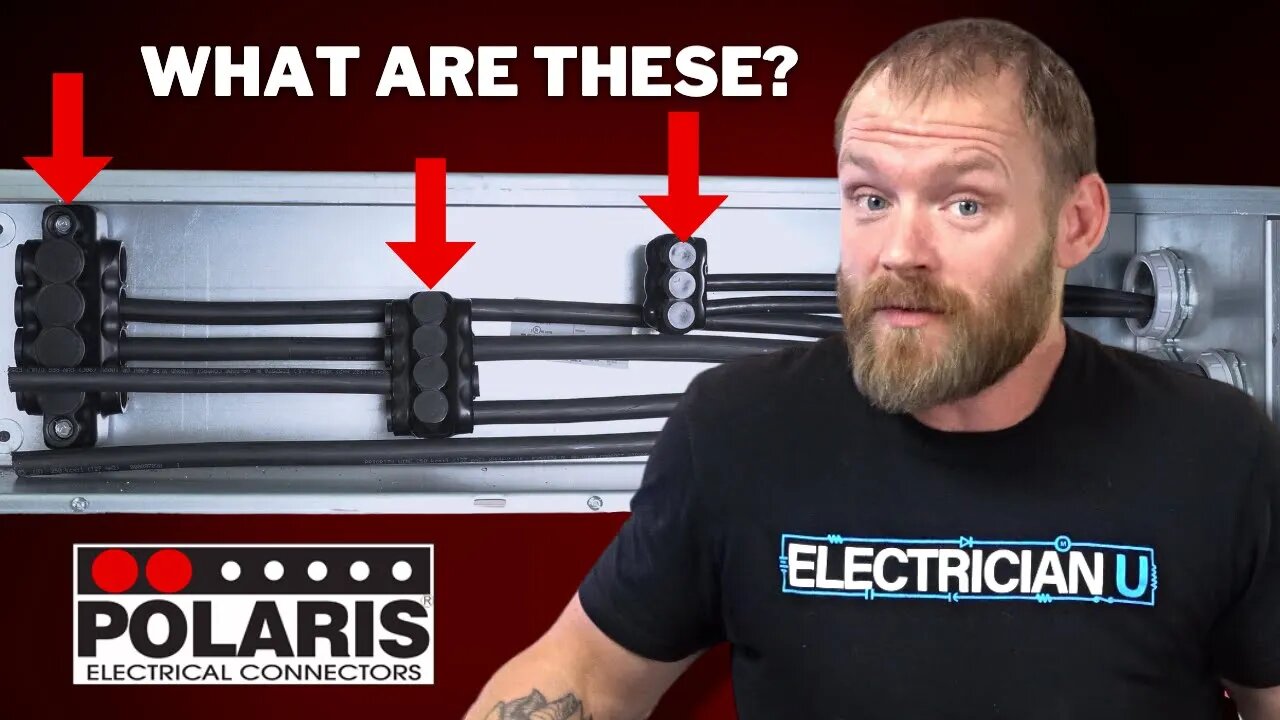

What Are Polaris Taps? How Do You Connect Large Gauge Wires?

Join this channel to get access to perks:

https://www.youtube.com/channel/UCB3jUEyCLRbCw7QED0vnXYg/join

⚡⚡ SPONSOR: Polaris Taps ⚡⚡

https://www.polarisconnectors.com/

We all know to use wire nuts to splice small loose wires in a junction box. But what about the larger ones? What to do there? In today’s episode, Dustin explores one of our shows sponsors- Polaris Connectors- and the multitude of options they provide for the larger wire terminations.

🤘⚡️MEMBERSHIP⚡️🤘

JOIN ELECTRICIAN U - become a member and get:

FREE Continuing Education every year

FREE Practice Exams

FREE Monthly Video Courses

FREE Weekly Live Instructor-Led Classes

FREE Monthly Educational Newsletter

Premium Members-Only Content

Private Discord Channel

Monthly Members-Only Discord Chats

Sign up here --- https://www.electricianu.com/electrician-u-membership/

🎧🎹MUSIC AND VIDEO:🎹🎧

https://www.facebook.com/descantmv

🎬✍️ART AND ILLUSTRATION:✍️🎬

https://www.daverussoart.com

In years past, to splice large wires, we had to use a Kearney (split bolt) connector to join the wires, then apply rubber insulating tape around the entire thing, before wrapping the entire thing with a high grade electrical tape. You may have a need to simply splice a set of wires or have a need to tap off of a larger feeder wire with smaller wires to feed different equipment. Labor intensive and time consuming for sure!! But thanks to Polaris Connectors, they have developed high grade termination blocks that are completely surrounded by a non-conductive rubberized coating. These terminations drastically cut down on installation time and much hated frustrations by the installing electricians!

The Polaris connectors are arranged by size of conductors, quantity of conductors, application needs, and installation environment. First, you choose the size of conductors you are going to be using. They are made with a wide range of cables in mind- #4-#14 on the smaller end, 3/0-#6 somewhere in the middle, up to 750kcmil-250kcmil on the larger end. Wire quantity is also to be considered when using these types of taps. You don’t want to just order the largest (which can be over 12 conductor capacity, although they do offer different options if space is an issue) as the taps are not overly small in size. Pick the quantity of conductors you are working with (add additional spaces if there is a possibility of future expansion) and order accordingly.

Another item to consider is the application itself. The connector can be ordered with the connection ports on one side if you are looking to splice conductors that enter/leave on the same side of the enclosure. They also offer a splice with the connection ports on opposite sides of the connector to be used if the wires are entering/leaving on opposite sides of the enclosure or if you are using it as a butt splice of sorts. If space is an issue in your scenario and you are needing to splice say 6 wires, they even offer a stacked connector that still provides spaces for 6 cables, but the ports are stacked on top of one another in lieu of all on the same plane. In other words, in lieu of 6 ports in one row, you can get them in 2 rows of 3. There are even models that have bolt down holes so you can bolt the splice to the back/bottom of the enclosure so your conductors can be trained out of the way and not just flopping around!

While most of our splicing needs are in a dry environment, there are instances where we would need a splice that is capable of living in a damp environment. Polaris Connectors offer a line of connector that is rated for wet/damp environments as well as a series that is capable of being used in a direct burial option.

A few tips to help when splicing wires that are larger in size. Make sure that you are not over stripping your conductors as this could leave you with exposed conductors that may lead to shorting. You also want to make sure to strip enough insulation from the wires, so the binding screw is in complete contact with the conductor and not insulation. Another tip is to plan where your taps will go within the enclosure ahead of time, and then cut/bend/shape your incoming/outgoing conductors to fit where you plan them to. It also helps to stagger your splices and not pile them all in one place in the enclosure as the splice point itself takes up more room than the conductor alone. The bolt down option of splice keeps your conductors where you place them! Lastly, make sure you are torquing your splices down to the manufacturers recommended torque values.

We hope this helped to show some of the options that are available when it comes to splicing wires. Do you have any tips you use when splicing large wires. Leave us a comment in the comments section and share them. Please continue to follow Dustin and Electrician U as we are constantly updating our content to assist our followers in becoming the best electricians that they can be.

-

0:50

0:50

Electrician U

1 year agoWhat Are Lumens?

13.2K4 -

LIVE

LIVE

OhHiMark1776

2 hours ago🟢 11-21-25 ||||| Two Morrows make a Day-to-Day? ||||| Livestream (2025)

42 watching -

GrimmHollywood

10 hours ago🔴LIVE • GRIMM HOLLYWOOD x SILVER FOX • GOLDEN YEARS • FINAL DAY • FLARE RACE • ARC RAIDERS •

1.4K -

1:11:24

1:11:24

The Daily Signal

3 hours ago $1.33 earned🚨BREAKING: Democrat Steals $5 Million from FEMA, Trump-Mamdani Meeting Gets Bizarre

3.7K -

1:02:11

1:02:11

BonginoReport

5 hours agoJ.D. Vance Threatens to Kill JD Vance?! - Nightly Scroll w/ Hayley Caronia (Ep.183)

90.9K31 -

3:09:50

3:09:50

Nerdrotic

16 hours ago $12.50 earnedWarner Bros Fire Sale! | Last Ronin CANNED | WICKED For Good REVIEW - Friday Night Tights 381

36.9K9 -

LIVE

LIVE

Akademiks

2 hours agoMeg Thee Stallion Back LYING again? Offset vs Finesse2x. 6ix9ine house robbed.. HERES WHO DID IT

818 watching -

LIVE

LIVE

SpartakusLIVE

2 hours agoFriday Night HYPE w/ YOUR King of Content

125 watching -

Blabs Life

2 hours agoPeter Jackson's King Kong: The Official Game of the Movie | Noob Plays

11.6K -

sim_n_shift

3 hours agoARC Raiders: Dropping Into the Chaos

14.5K