Premium Only Content

The Basics of Manganese Phosphating (Parkerizing) in HD

AMAZON Store: https://amzn.to/2H7Lq6Y

PATREON: https://www.patreon.com/iv8888

JOIN USCCA LEGAL SELF DEFENSE NETWORK: http://usccapartners.com/IV8888

CHECK OUT OUR MUSIC CHANNEL: https://www.youtube.com/c/Guitarsenal

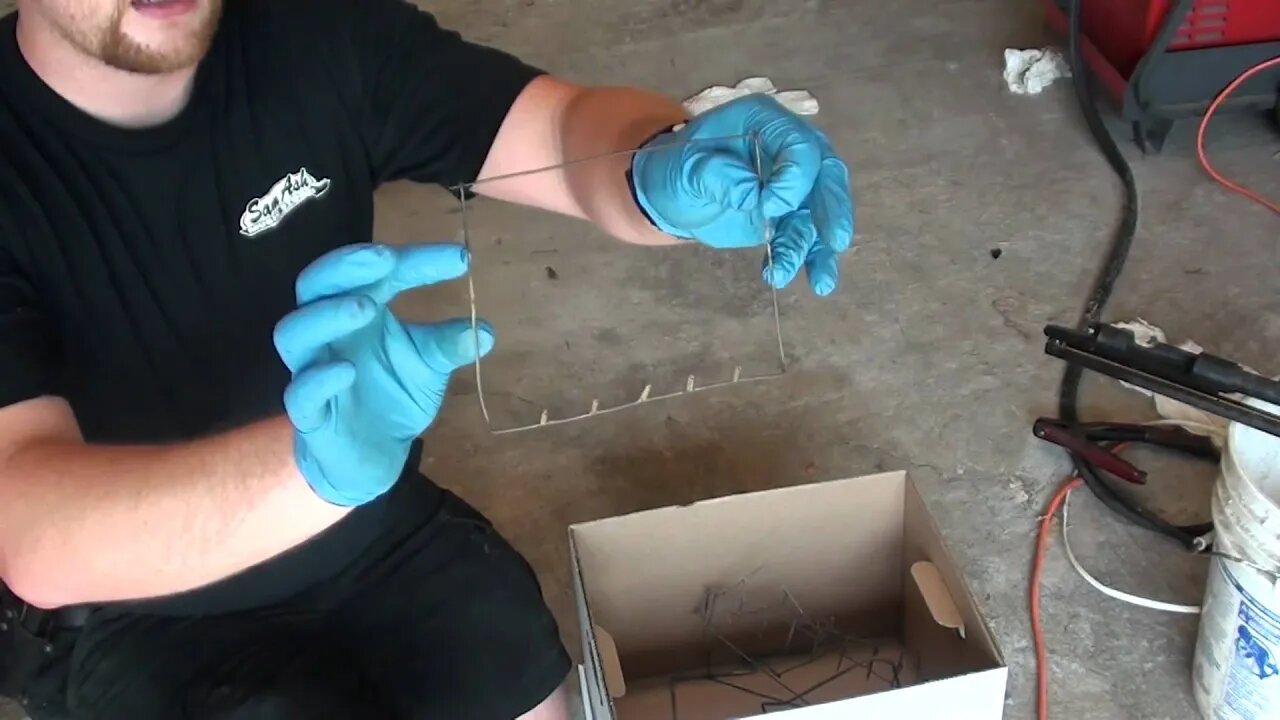

This video shows a fairly good breakdown of the process considering I don't have a camera man to help me film.

I did leave out a few basic things:

1. Invest in a brand new spray bottle and fill it with Acetone or similar degreaser. If you happen to accidentally get a finger print or drop of sweat on your freshly prepared part, you can spray it off with the acetone.

2. Do not skimp on the metal preparation. With the blasting, make sure you are going for a consistent pressure with your air regulator, and that you are going over all the parts of the metal in a even fashion. 90 percent of the finish you get with ANYTHING you are doing, is going to come down to the preparation of the part to be finished. This applies to anything I.E. painting, duracoat, metal refinishing, etc.

3. In terms of degreasing, if you are going to opt for a simple green/purple power bath, make SURE THAT YOU WEAR GLOVES WHILE HANDLING THE METAL FROM THAT POINT ON ESPECIALLY IF YOU DO NOT HAVE A DEGREASER LIKE ACETONE ON HAND TO FIX YOUR MISTAKES. This is very important.

4. You may want to invest in a basic sweat band to keep drops of sweat from falling on your work.

5. If you are doing multiple pieces, make sure you are changing your water rinsing bath out every hour or so.

6. If you want a very traditional parkerizing like you see on WW2 firearms, opt for a zinc phosphating, then allow the parts to sit in a bath of 20-50W motor oil for about 3 months. If you have access to large quantities of cosmoline, that is even better. Warm the cosmoline in a bath and dip the freshly parked parts to insure an even and thorough coating. You will get a beautiful greenish/bluish tint in the metal.

7. With the etching process, do not allow the metal parts to remain in the phosphates for too long after they stop bubbling. At this point, the solutions are actually eating the metal. For instance, if you left a 1911 slide in the heated solutions for say 2days, it would likely be unusable or maybe even gone...lol.

8. If in doubt....DEGREASE, DEGREASE, DEGREASE.

9. Don't skimp on oil/water filters for your compressors.

10. If you really want to be fancy, once you remove your freshly parked part from the tank, blow it bone dry, and instead of following up with a healthy coating or oil, duracoat it.

DISCLAIMER: Our videos are strictly for documentary, educational, and entertainment purposes only. All shooting is performed on state-approved firing ranges under the supervision of trained professionals. Imitation or the use of any acts depicted in these videos is solely AT YOUR OWN RISK. All work on firearms should be carried out by a licensed individual and all state and federal rules apply to such. We (including YouTube) will not be held liable for any injury to yourself or damage to your firearms resulting from attempting anything shown in any of our videos. We do not endorse any specific product and this video is not an attempt to sell you a good or service. We are not a gun store and DO NOT sell or deal in firearms. Such a practice is heavily regulated and subject to applicable laws. We DO NOT sell parts, magazines, or firearms. We are not instructing our viewers on how to modify firearms, accessories or otherwise to change their basic legal function. These videos are free to watch and if anyone attempts to charge for this video notify us immediately. By viewing or flagging this video you are acknowledging the above.

Fair Use: In the rare instance we include someone else’s footage it is covered in Fair Use for Documentary and Educational purposes with the intention of driving commentary and allowing freedom of speech.

-

26:57

26:57

Iraqveteran8888

1 year agoIs It Worth Reloading Your Own Ammo?

10.8K32 -

8:28:19

8:28:19

Dr Disrespect

10 hours ago🔴LIVE - DR DISRESPECT - BATTLEFIELD 1 - FULL GAME

139K7 -

1:39:26

1:39:26

Glenn Greenwald

5 hours agoStephen Miller's False Denials About Trump's Campus "Hate Speech" Codes; Sohrab Ahmari on the MAGA Splits Over Antitrust, Foreign Wars, and More | SYSTEM UPDATE #495

86.8K30 -

1:57:28

1:57:28

Omar Elattar

6 hours agoThe $300M CEO: "The One Skill That Made Me Rich In 15 Different Countries!"

7.19K -

LIVE

LIVE

xXFadedAngelXx

1 hour ago180 HOURGLASS PULL! Wisdom of Sea and Sky (Pokemon TCG Pocket) Then some RL with Meditayte later

13 watching -

8:14

8:14

MattMorseTV

6 hours ago $2.87 earnedTrump just DROPPED the HAMMER.

13.4K12 -

LIVE

LIVE

TruthStream with Joe and Scott

1 day agoThrow Away. Do Not Eat

157 watching -

30:21

30:21

Friday Beers

5 hours ago $2.13 earnedOur Brutal Golf Challenge: Hot Wings Roulette

45.4K1 -

2:58:40

2:58:40

Barry Cunningham

6 hours agoPRESIDENT TRUMP SPEECH AT MAKING HEALTH TECHNOLOGY GREAT AGAIN! EVENT AND MORE NEWS!

66.5K29 -

Dragoon_B

5 hours agoDragoon - Counter Strike - Premier Grind - Breaking 5k Rank

202