Premium Only Content

Johnson Outboard Lower Unit Crack Repair/Rebuild #4

Video #4 of the Johnson GT 150 lower unit crack repair/rebuild is on the weld repair of a crack found in the nose of the lower unit where I believe the water seeped into the case which caused the cracking of the case in winter storage. What you will see being completed in this series of videos will be questionable to many. This is the second lower unit I have repaired in this same fashion, and both went on for many more years of service and saved the owners in the $1000.00 range. If you attempt this I cannot stress enough do not force anything, take your time. Please check video #1 for more of a description.

Link to some tools, including the pinion nut adapter kit:

http://www.sterndrive.info/outboardmotor/id2.html

Link to exploded view of the lower unit: http://www.sterndrive.info/outboardmotor/1978_1998_v4_90_degree_.html

Buy snap ring pliers: https://www.offshoremarineparts.com/93-13-1045.html?gclid=Cj0KCQiA5aTUBRC2ARIsAPoPJk9wFPQBsX-Hotb4B7Ysnl0JFJ8QXMiLgohL8303qvf6221euzjL2qIaAnfrEALw_wcB

At the end of this video I will include a picture of the OMC lower unit diagram that is what the numbers in the video refer to. There will also be a link in the video description to that diagram.

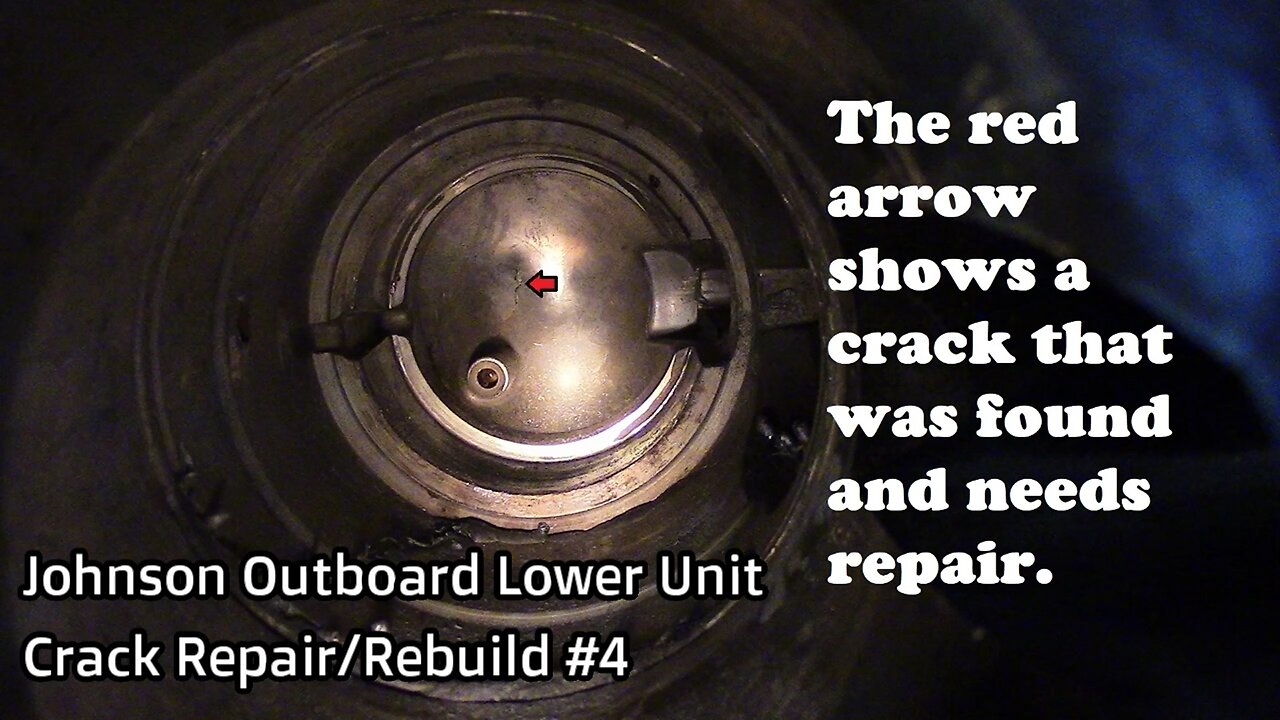

During my inspection of the lower unit I found this crack which is probably where the water got into the case, he probably hit a rock with the lower unit and cracked it but didn’t know.

This is why it is imperative you check the grease for water each year in the fall prior to storage.

Time to make some noise, I beveled out the crack in the nose and need to weld repair that first.

Cast aluminum welding is a time consuming process that is why I am showing this whole section uncut.

I use 100% argon for a shielding gas.

The crack will open while welding it’s easy to see it you must weld it from end to end with penetration so you can sand it smooth.

There are always some small pin holes that need to be gone over after grinding, that’s cast aluminum.

You can see I am not adding filler wire at this time, I am boiling/burning out the contaminants in the base material.

The porosity just keeps coming back you just have to relax and continue until it boils away.

If the contaminants will not boil out you will need to grind them out.

Now to clean up some of the skeg, and complete a little build up there, come back for video #5 to see me repair and straighten the skeg, and grind the inside of the case. Thanks for watching.

https://www.youtube.com/@HRIservicesllcSturgeonBay

https://www.instagram.com/hri_services/

https://www.facebook.com/HRIServicesllc/

https://www.millerwelds.com/

-

LIVE

LIVE

Joker Effect

41 minutes agoINTERVIEWING Rumble Gaming community members: Viewbotting and how they see the current landscape.

425 watching -

1:45:53

1:45:53

Nerdrotic

3 hours ago $9.04 earnedUnravelling the Secrets of Skinwalker Ranch | Forbidden Frontier #115

55.8K4 -

41:56

41:56

Athlete & Artist Show

4 hours ago $0.27 earnedAustin Ekeler: Going From "0 Star Recruit" To Leading The NFL In TD's, New Fan App | FROM THE VAULT

7.53K1 -

2:46:49

2:46:49

Barry Cunningham

9 hours agoNOW THEY FEAR US! | RFKJR STRIKES BACK | JD VANCE ON PRESIDENT TRUMP | AND MORE NEWS!

51.6K24 -

LIVE

LIVE

Spartan

4 hours agoCharlotte Qualifier watch party + Ranked and Expedition 33

97 watching -

6:09:54

6:09:54

bigbossrobinson

7 hours agoLIVE - DOUBLE IMPACT - RESIDENT EVIL 4 & METAL GEAR SOLID Δ: SNAKE EATER

21.8K -

8:18

8:18

MattMorseTV

6 hours ago $5.81 earned2.2 MILLION in ONE YEAR.

35.1K121 -

14:37

14:37

Colion Noir

9 hours agoCanadian Police Chief Urges Citizens To Comply With Home Invaders And Hide

72K87 -

3:10:59

3:10:59

OVERKLOC

4 hours ago🔴LIVE - CHILL SUNDAY GAMING - WHO KNOWS WHAT WE'LL PLAY

14.2K -

5:58:37

5:58:37

FrizzleMcDizzle

6 hours ago $0.61 earnedNightReign - Lies of P: Overture after - Come hang out

14.3K