Premium Only Content

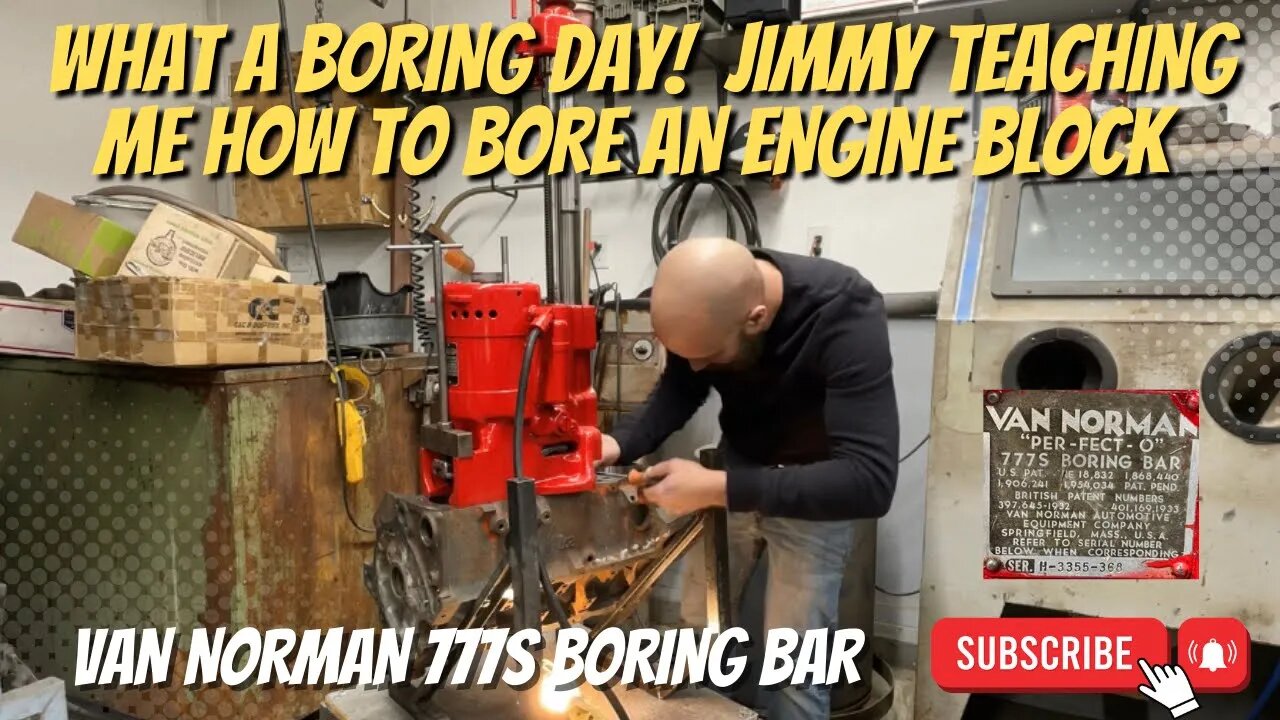

Learning How To Bore an Engine With a Van Norman 777s… Quite the Boring Day! #engine

Well, it was quite the boring day.... get it? I am finally feeling better after being down for three weeks from being sick so naturally I decided to back to working on automotive stuff. I have all the parts now to build Todd's 388 cubic inch small block stroker and the Jimmy and I have already done a little work to the engine block. Before we assemble this small block Chevy engine for the 1980 Camaro Z/28, we will need to bore, hone, and chamfer the cylinders. Before I was down for the count, Jimmy had been giving me a crash course lesson in how to use a Van Norman 777S boring bar. Well, today I am going to get a crash course on how to operate it. In this video we go over on how to set it up, measure for the boring cuts, and also explain the overall process. Jimmy has worked in and owned machine shops for many many decades, longer than I have been alive. He has been building race engines, dragster chassis, and all other kind of engines of street and strip applications. Jimmy has definitely lived the machine shop life!! So before we install the crankshaft, pistons, camshaft, cylinder hears, etc... we will need to machine this four bolt main engine block. The goal with this build is to get around 500 horsepower out of a small block while remaining street friendly and use pump gas. I will say, this was a timely process where I learned a lot and teamwork was key. Engine machining is a trade I want to learn more about and Jimmy is going to assist me with that. I will also be doing a video at some point covering the honing and chamfering of this build. Stay tuned!

#machineshop #builtnotbought #learning

-

1:04:59

1:04:59

Man in America

11 hours ago“Summoning the Demon” — The AI Agenda Is FAR WORSE Than We Know w/ Kay Rubacek

46.5K30 -

2:16:48

2:16:48

Tundra Tactical

9 hours ago $0.11 earned🎯💥 The World’s Okayest Gun Show 🔫😂 | LIVE Tonight on Rumble!

27.2K -

3:36:03

3:36:03

Mally_Mouse

1 day ago🌶️ 🥵Spicy BITE Saturday!! 🥵🌶️- Let's Play: Tower Unite!

53.6K2 -

58:59

58:59

MattMorseTV

9 hours ago $1.49 earned🔴Trump just BROKE Newsom.🔴

68.3K84 -

18:14

18:14

Her Patriot Voice

9 hours agoWho Is WORSE for NYC: Trump Girl or Socialist?

51.1K33 -

3:39:42

3:39:42

SavageJayGatsby

8 hours agoSpicy Saturday with Mally! | Road to 100 | $300 Weekly Goal for Spicy Bites!

49.2K1 -

3:35:50

3:35:50

FomoTV

10 hours ago🚨 Swamp Theater: FBI Raids Bolton 🕵 Still NO Epstein Files, Trump's Troops & the Red Heifer Hoax 🐂 | Fomocast 08.23.25

22.4K7 -

6:04:40

6:04:40

Akademiks

13 hours agoRoc Nation & Meg Thee Stallion did a 7 HOUR Deposition with me. Drake Secret Kid Finally Revealed.

58.7K2 -

24:19

24:19

Stephen Gardner

10 hours ago🚨BREAKING: FBI Raid of John Bolton’s House Reveals THIS!

61K143 -

8:31

8:31

MattMorseTV

12 hours ago $1.19 earnedTexas just did the IMPOSSIBLE.

51.4K68