Premium Only Content

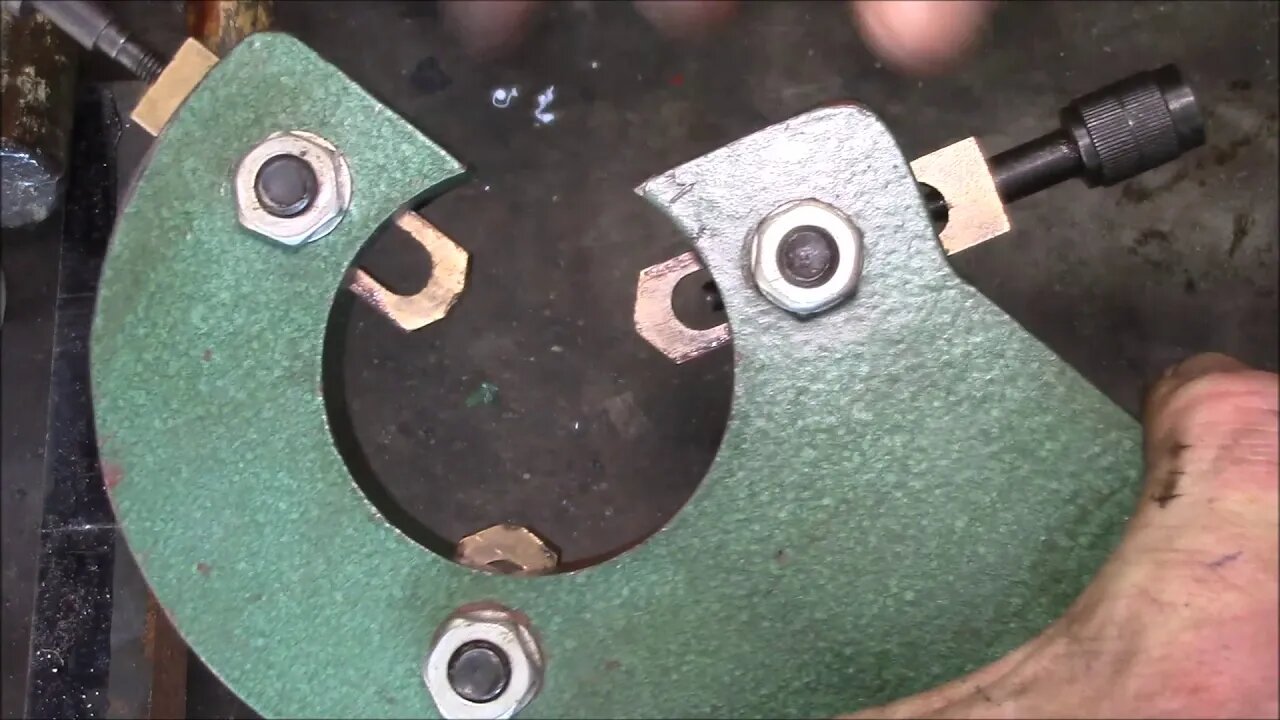

Tuning up the Grizzly G4000 Lathe Steady Rest

Cleaning up the slots in the lathe steady rest to make it easier to use.

In hindsight, I should have done this years ago. However, with use, the original paint that had been jamming up the slots in the steady rest had softened to the point it came out easily. Used a small triangle file to remove any roughness and bits of paint from the bottom, sides and corners of the machined slots. Brass inserts were cleaned up and a light coat of grease in the slots and all the pieces moved easily.

Since changing to the 12L14 steel, the steady rest alone is sufficient for machining the steel shift weights, seen in an earlier video. Before, with hot rolled mild steel, we had to add a live center to hold the material for machining. This saves the time of drilling the center holes on each end of the stock as well as allows for a smaller tooling stick out since there's no longer a need for the carriage to clear the live center.

More to come...

Subscribe for more content like this

Comment, rate, share & click the bell icon

And as always, thanks for watching

-

LIVE

LIVE

I_Came_With_Fire_Podcast

11 hours agoThe Normalization of Political Violence | Right Wing In-Fighting | China Chooses China

98 watching -

UPCOMING

UPCOMING

PandaSub2000

6 hours agoLIVE 10:30pm ET | BUZZ TRIVIA with Chat!

152 -

LIVE

LIVE

ThisIsDeLaCruz

22 minutes agoWhat Fans Never Hear: Pearl Jam’s Audio Engineer Tells His Story

70 watching -

1:39:58

1:39:58

Glenn Greenwald

4 hours agoWhy Did Zohran Win & What Does it Mean? Plus: Dick Cheney, "Hero of the Resistance" | SYSTEM UPDATE #543

98.3K56 -

LIVE

LIVE

This is the Ray Gaming

37 minutes agoRAYmember RAYmember the 5th of November | Rumble Premium Creator

42 watching -

1:44:39

1:44:39

vivafrei

3 hours agoArctic Frost is Bigger Scandal than you Think!! Live with Former Green Beret Ivan Raiklin!

36.6K27 -

Turning Point USA

2 hours agoTPUSA Presents This Is the Turning Point Tour LIVE with Eric and Lara Trump at Auburn University!

32.8K8 -

LIVE

LIVE

XDDX_HiTower

1 hour agoBATTLEFIELD 6 REDSEC! [RGMT CONTENT Mgr.

53 watching -

LIVE

LIVE

Joker Effect

1 hour agoSTREAMER NEWS: What actually occurred at Dreamhack ATL. Frontier Airlines. Kick Staff Trolled me?!

478 watching -

LIVE

LIVE

VapinGamers

1 hour agoBF6 RedSpec - Nothing but Wins and New Rum Bot Testing - !rumbot !music

25 watching