Premium Only Content

This video is only available to Rumble Premium subscribers. Subscribe to

enjoy exclusive content and ad-free viewing.

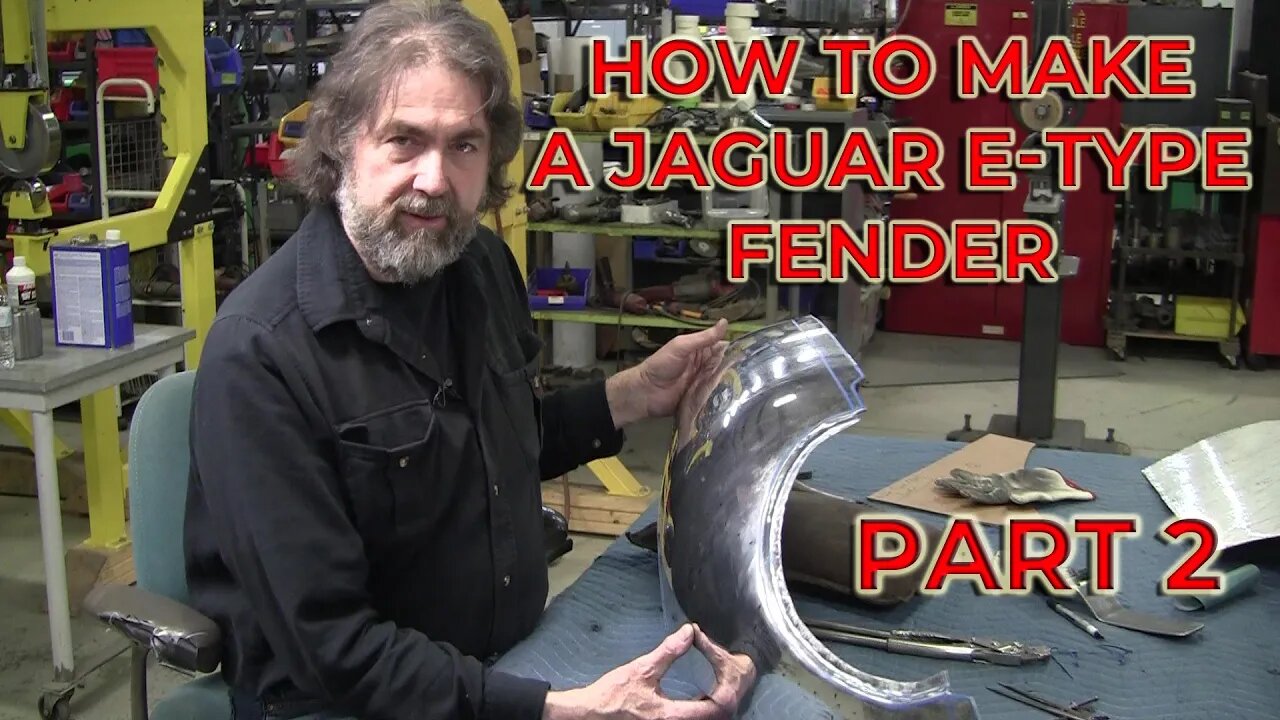

How to build a Jaguar E-Type fender (Part 2)

5 years ago

3

https://www.proshaper.com

Our Amazon Storefront:

https://www.amazon.com/shop/proshaper

Part 2 of how to build and Jaguar E-Type Fender Wray completes the area value of the panel to match the flexible shape pattern. Then using the english wheel as a fulcrum, arranges that panel to fit the gauges created from the original fender. After trimming down the sheet metal Wray uses the tipping wheel and then hammer and dolly to bend the flanges and create the seat for the light.

Email: Wray@Proshaper.com

Website: https://www.proshaper.com

Facebook: https://www.facebook.com/ProShaper/

Instagram: https://www.instagram.com/proshaper/

Twitter: https://twitter.com/ProshaperM

Linkedin: https://www.linkedin.com/company/proshaper/

Loading comments...

-

40:55

40:55

Bent Sprocket Tech

3 years agoAquanut 1 Build (Part 2) - Electrical

16 -

16:08

16:08

Bent Sprocket Tech

3 years agoAquanut 1 Build (Part 4) - Improvements

16 -

22:19

22:19

ProShaper

3 years ago33 Ford Fender repair (Part 2): Forensic Files

153 -

22:19

22:19

ProShaper

3 years ago $0.01 earned33 Ford Fender repair (Part 2): Forensic Files

195 -

10:04

10:04

Bent Sprocket Tech

3 years agoAquanut 1 Build (Part 3) - Testing

12 -

34:21

34:21

Bent Sprocket Tech

3 years agoAquanut 1 Build (Part 1) - Mechanical

8 -

23:47

23:47

ProShaper

3 years ago33 Ford Fender (Part 3) The Patch Panel

62 -

23:47

23:47

ProShaper

3 years ago33 Ford Fender (Part 3) The Patch Panel

44 -

7:43

7:43

Redbeard39

3 years agoFuel Tank Build (Part 2)

18 -

1:02:42

1:02:42

Dialogue works

1 day ago $3.19 earnedJohn Helmer: Trump Ditches Ceasefire? Despite EU & Zelensky Pressure

46.9K18