Premium Only Content

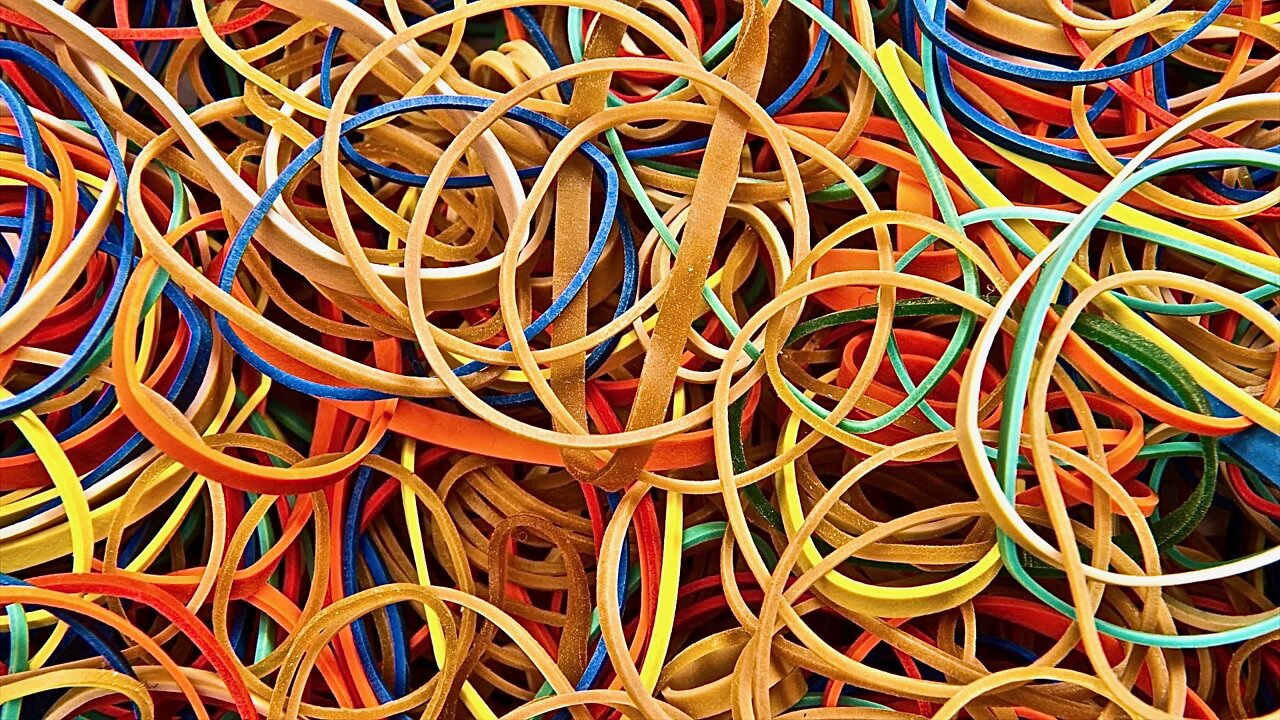

How Rubber Bands Are Made - Intensive Process

Rubber bands are still made from organic rubber because it offers superior elasticity. Natural rubber comes from latex, a milky fluid composed primarily of water with a smaller amount of rubber and trace amounts of resin, protein, sugar, and mineral matter. Most non-synthetic industrial latex derives from the rubber tree (Hevea brasiliensis), but various equatorial trees, shrubs, and vines also produce the substance.

Within the rubber tree, latex is found between the external bark and the Cambium layer, through which the tree's sap flows. Distinct from the sap, latex serves as a protective agent, seeping out of and sealing over wounds in the tree's bark. After being extruded, the rubber tubes are forced over aluminum poles called mandrels and cured in large ovens. Finally, the tubes are removed from the mandrels and fed into a cutting machine that slices them into finished rubber bands.

The Manufacturing

Process

Processing the natural latex

1 The initial stage of manufacturing the harvested latex usually takes place on the rubber plantation, prior to packing and shipping. The first step in processing the latex is purification, which entails straining it to remove the other constituent elements apart from rubber and to filter out impurities such as tree sap and debris.

2 The purified rubber is now collected in large vats. Combined with acetic or formic acid, the rubber particles cling together to form slabs.

3 Next, the slabs are squeezed between rollers to remove excess water and pressed into bales or blocks, usually 2 or 3 square feet (.6 or .9 square meter), ready for shipping to factories. The size of the blocks depends on what the individual plantation can accommodate.

Mixing and milling

4 The rubber is then shipped to a rubber factory. Here, the slabs are machine cut (or chopped) into small pieces. Next, many manufacturers use a Banbury Mixer, invented in 1916 by Femely H. Banbury. This machine mixes the rubber with other ingredients—sulfur to vulcanize it, pigments to color it, and other chemicals to increase or diminish the elasticity of the resulting rubber bands. Although some companies don't add these ingredients until the next stage (milling), the Banbury machine integrates them more thoroughly, producing a more uniform product.

5 Milling, the next phase of production, entails heating the rubber (a blended mass if it has been mixed, discrete pieces if it has not) and squeezing it flat in a milling machine.

Extrusion

6 After the heated, flattened rubber leaves the milling machine, it is cut into strips. Still hot from the milling, the strips are then fed into an extruding machine which forces the rubber out in long, hollow tubes (much as a meat grinder produces long strings of meat). Excess rubber regularly builds up around the head of each extruding machine, and this rubber is cut off, collected, and placed back with the rubber going into the milling machine.

Curing

7 The tubes of rubber are then forced over aluminum poles called mandrels, which have been covered with talcum powder to keep the rubber from sticking. Although the rubber has already been vulcanized, it's rather brittle at this point, and needs to be "cured" before it is elastic and usable. To accomplish this, the poles are loaded onto racks that are steamed and heated in large machines.

8 Removed from the poles and washed to remove the talcum powder, the tubes of rubber are fed into another machine that slices them into finished rubber bands. Rubber bands are sold by weight, and, because they tend to clump together, only small quantities can be weighed accurately by machines. Generally, any package over 5 pounds (2.2 kilograms) can be loaded by machine but will still require manual weighing and adjusting.

Quality Control

Sample rubber bands from each batch are subjected to a variety of quality tests. One such test measures modulus, or how hard a band snaps back: a tight band should snap back forcefully when pulled, while a band made to secure fragile objects should snap back more gently. Another test, for elongation, determines how far a band will stretch, which depends upon the percentage of rubber in a band: the more rubber, the further it should stretch. A third trait commonly tested is break strength, or whether a rubber band is strong enough to withstand normal strain. If 90 percent of the sample bands in a batch pass a particular test, the batch moves on to the next test; if 90 percent pass all of the tests, the batch is considered market-ready.

Music: Twilight Streets by Dhruva Aliman

Amazon - https://amzn.to/2B9tGa7

https://music.apple.com/us/artist/dhruva-aliman/363563637

https://dhruvaaliman.bandcamp.com/album/road-of-fortunes

http://www.dhruvaaliman.com/

Spotify - https://open.spotify.com/artist/5XiFCr9iBKE6Cupltgnlet

#Howitsmade #Rubber #manufacturing

-

6:57

6:57

Seeker Land

3 months agoMAN AND BEAST - Part 13

66 -

LIVE

LIVE

Spartan

1 hour agoStellar Blade Hard Mode with death counter (First Playthrough)

57 watching -

1:02:11

1:02:11

VINCE

4 hours agoPelosi Is Passing The Torch - Who's Next? | Episode 164 - 11/07/25 VINCE

157K114 -

LIVE

LIVE

GloryJean

2 hours agoWINNING All Day Long Baby 😎

74 watching -

LIVE

LIVE

SOLTEKGG

2 hours agoGOING FOR THE WIN WORLD RECORD - BF6 Giveaway

36 watching -

1:06:37

1:06:37

Chad Prather

16 hours agoApplying The POWER Of Christ To Your Life!

83.2K33 -

LIVE

LIVE

LFA TV

15 hours agoLIVE & BREAKING NEWS! | FRIDAY 11/7/25

3,592 watching -

1:05:59

1:05:59

Crypto Power Hour

16 hours ago $0.21 earnedTop 10 Cryptocurrency Staking Platforms

76.6K10 -

35:53

35:53

Mike Rowe

1 day agoBreaking Down Bill Gates' 3 Tough Truths About Climate | Alex Epstein #457 | The Way I Heard It

90.2K53 -

23:22

23:22

Stephen Gardner

1 day ago🚨BREAKING: Mamdani Won and What Trump EXPOSES About It is SHOCKING!!

65.1K147