E-book: Oil Pyrolytic Vortex Burner 10-40kW with a Blue Flame Burning Various Types of Waste Oils

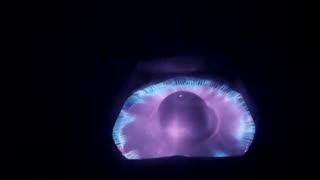

The actual burning that you see in the video is just the final visible stage of many degrees of burning and mixing of flames inside the burner, where the combustion occurs with the addition of pressurized air in a multiple-stage swirling flushing of burning vapors that occurs continuously inside the burner.

Proper combustion can be controlled by primary, secondary, and tertiary access to pressurized air, air volume, and air pressure, nozzle orientation, and proper construction. The process that occurs there takes place at very high temperatures and pressures than the surrounding atmospheric pressure. All of this together ensures the best possible combustion!

II worked on this burner for many years, developed many variants, and this one is the best in terms of operation, simplicity, low power consumption, and provides very high performance and amazing combustion cleanliness. Everything is designed so that any DIY enthusiast can make it at home from common materials found at a scrap yard. This is also described in the book. No electronics are needed! No compressor is needed either!

The electric power consumption of the burner is 60-120W per hour of operation for one or two blowers, depending on the desired performance (220VAC). The burner can also be operated on 12VDC. The consumption is 1.5-3 liters of used oil per hour.

Unique features and advantages of this burner over the competition:

- Burns all types of oil without residue.

- Burns oil mist at extremely high temperatures.

- After burning, dry ash remains depending on the oil used.

- It can be made from residues found in scrap yards and junkyards.

- It can be made at home.

- It can be made very cheaply. No advanced technology is required.

- It emits no visible emissions or chimney smoke.

- Any toxic substances contained in the oil vapour are burned off by high temperatures in several stages.

- It has a small footprint and fits into boilers, possibly with a little modification by the user.

Advantages for the burner user:

- Zero fuel costs, fuel is free.

- Increase in heating system performance.

- Reduction of emissions compared to the original wood and coal heating

- Replaces the gas burner with minimal modification to the gas boiler.

- Easy maintenance and operation.

- Easy to repair, any mechanic, welder, locksmith can repair.

- Low cost of burner production as discarded stuff can be used everywhere.

- Low cost of burner installation. Sometimes requires a slight modification of the boiler.

- It is possible to operate the burner without any electronics.

- The user can repair and stop everything himself.

Application and application areas of the pyrolytic burner:

- Use for heating in family houses.

- Use in companies in process plants for heating liquids

- Use in companies as heating.

- Use in heating of gymnasiums, club rooms, workshops, warehouses.

- Use for melting metals, alloys and metal casting.

- Use for heating metals for forging.

- Use for steam generation.

Technical specifications:

- Burner output 10-27kw with one fan.

- Burner output 10-40kW with two fans

- Current consumption at 220V 60W depending on fan or 120W.

- Oil consumption 1,5-1,7l per hour, or 2-3 l per hour in

more powerful version with two fans.

A license for one person for an e-book, which describes how to make the burner described above and shown in the preview, can be purchased from me for 40 EUR

Video pyrolytic oil burner.

-

0:20

0:20

Zejda

7 months agoE-book: Oil Pyrolytic Vortex Burner 10-40kW with a Blue Flame Burning Only High-Temperature Vapors

33 -

0:12

0:12

Zejda

7 months agoOil Pyrolytic Vortex Burner 10-40kW with a Blue Flame How to made burner for Waste Oils

30 -

12:19

12:19

VOGMAN

1 year agoSimple easy build DIY waste oil burner - by VOGMAN

1642 -

7:20

7:20

VOGMAN

1 year agoWaste Oil Burner - Improvements - by VOGMAN

881 -

0:19

0:19

Juniormints11

3 years ago $0.01 earnedwaste oil burner

1751 -

35:23

35:23

Mark Young

1 year agoFirebox "Wood Flame" Gas Burner -Trangia Alternative? Comprehensive Review

42 -

0:59

0:59

intelligenceisneeded

1 month agowaste oil burner

269 -

0:32

0:32

outdoorswithWade

2 years agoMy first waste oil burner

83 -

0:25

0:25

outdoorswithWade

2 years ago $0.01 earnedWaste oil forge

49 -

0:15

0:15

intelligenceisneeded

1 month agowaste oil burner furnace

265